At a Glance

- The healthcare and pharmaceutical sector is changing rapidly with the integration of latest technologies.

- Digitization is on the agenda of major (and even most of the small-scale) pharma companies to enhance end-to-end operations management.

- Pharma companies face challenges pertaining to manufacturing, quality control, serialization, supply chain management, process automation and more. Businesses can address these challenges with the help of cutting-edge tools and technologies.

The year 2020 has been particularly demanding for the healthcare and pharmaceutical industry. The increased need for newer or existing therapeutics and demand for a vaccine to curb the ongoing Covid-19 pandemic has put pharmaceutical manufacturers at the frontline. The challenges and pain areas that the pharma sector was dealing with became all the more prominent in 2020.

Pharmaceutical operations management has seen many changes in the past decade and these changes have accelerated because of rapid digitization. Top executives and decision-makers are looking for transformation technologies that can streamline operations, fortify quality control and optimize supply chain management. The manufacturers are looking at ways to transition from batch to continuous manufacturing. To say that the pharmaceutical and biotechnology sector is navigating through times of transformation would not be an exaggeration.

According to Mckinsey and Company, more than 65 percent reduction in deviations and over 90 percent faster closure times have been recorded in first real-life use cases of pharma manufacturing labs (that adapted emerging technologies such as automation and advanced analytics amongst others).

This period of transformation and disruptions is particularly testing for operations management in the pharmaceutical manufacturing sector. Here is a look at some of the challenges in pharmaceutical industry in this area:

1.The Shortcomings of Batch Manufacturing:This rather conventional method of manufacturing comes with its set of problems such as increased efforts and costs. Production in batches also entails batch-wise quality control increasing employees’ downtime. Batch manufacturing is also cumbersome to manage as it requires multiple storage facilities, multiple process reports, various checkpoints and overall increased chances for errors. Pharmaceutical Operations require agility and customized production and the batch manufacturing process falls short by being a rather ‘set’ process.

2.Quality Control and Quality Assurance Challenges:Quality is very obviously a non-negotiable aspect in the pharma industry. In Pharmaceutical operational management, regular quality checks and observing all deviations are a must. However, maintaining quality comes with its set of challenges. Many manufacturers often struggle with clearing quality control checks for raw materials as well as manufactured batches. There is a need to test every batch for generic and customer-specific potency requirements thoroughly, ensure proper storage conditions at every facility, report and record observations, perform in-process quality testing, etc.

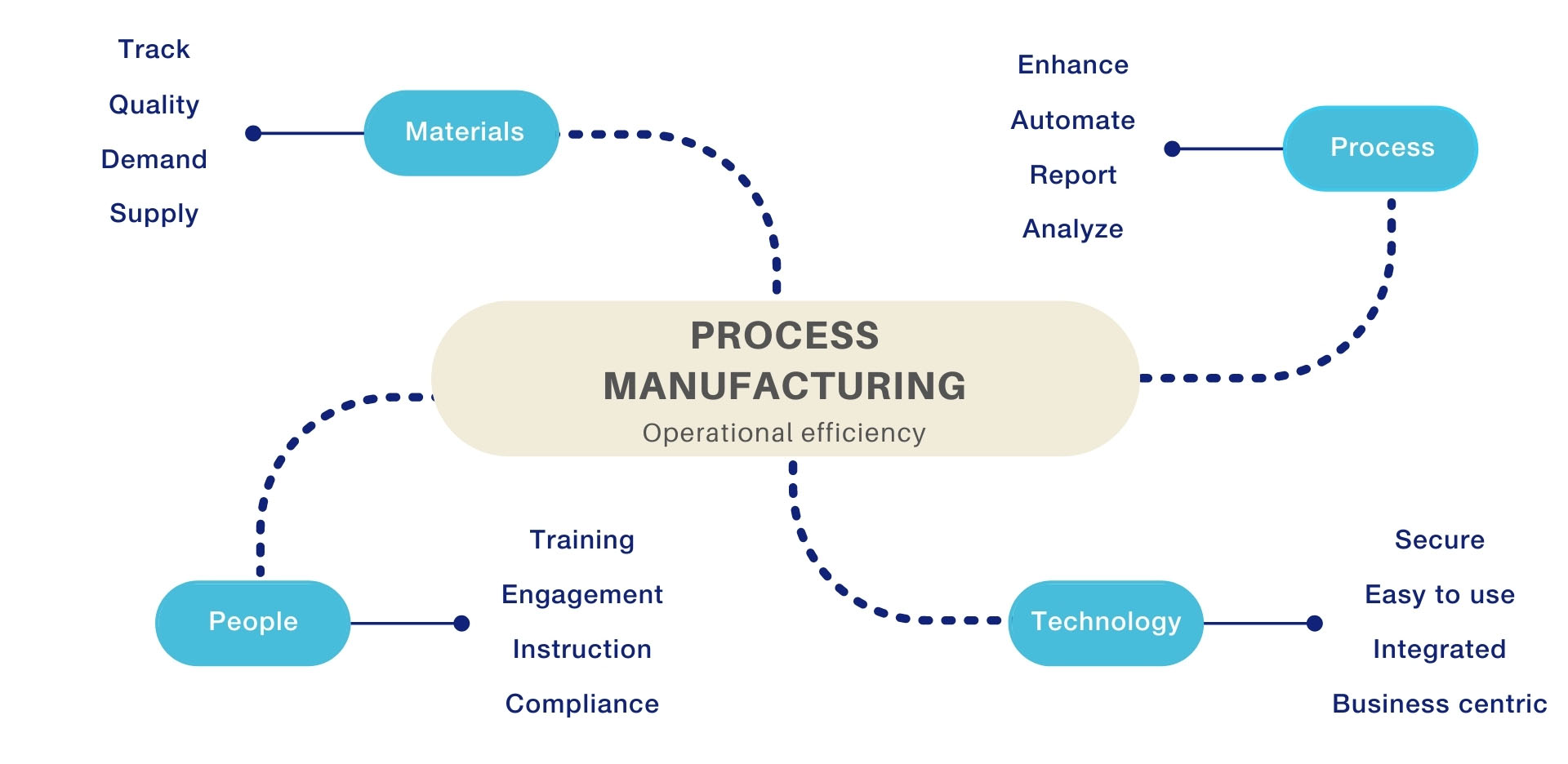

Figure 1:Major Challenge Areas: Pharma End-to-end Operations Management

3.Inventory Management Issues:If the current pandemic has disrupted a branch of pharmaceuticals completely, it would be supply chain and inventory management. Unpredictable demand patterns, over or under stocking, false forecasting have been some major challenges of pharmaceutical manufacturers and vendors. Major and small-scale pharmaceutical companies face issues with quantification and replenishment decisions.

4.Challenges with Digital Transformation in the Pharmaceutical Industry:Pharmaceutical, life sciences and biotech companies are going the digital way to expedite processes, integrate automation and streamline their operations. This journey of digitization in the pharmaceutical industry can be a daunting one for companies as they struggle with moving to newer systems. Top executives need to factor in the cost of digital transformation, expenditure to upgrade their IT infrastructure and budget to upskill their workforce.

To overcome these challenges, pharmaceutical companies need to rethink their operational management strategies. With the help of advanced systems such as the Microsoft Dynamics 365 Finance and Operations, biopharmaceutical manufacturers can make strides in their digitization journey while systematically managing their end-to-end operations. The strength is in the Microsoft cloud-based ecosystem that integrates the enterprise ERP with process automation, analytics, AI, etc.

Figure 2:All Microsoft apps under one umbrella

Figure 3:Microsoft Dynamics 365 Finance and Operations quick glimpse

Here are some of the prominent ways that Dynamics 365 is helping pharmaceutical companies build efficiency in operations management:

- Automation of processes leading to reduced manual efforts, better time management, decreased operational costs and an overall reduction in time-to-market.

- In-system generation of reports, invoices, and labels for quality checks, drug batches and related processes.

- Efficient quality control and assurance with the help of customized processes.

- Efficient monitoring of inventories to avoid wastage or stock-outs.

- Real-time tracking of supply chain and centralized connectivity between various stockholder, creating a harmonized system that can run smoothly.

- Effective raw material planning and in-system purchase order generation with timely reminders and customization options.

These and many such features make a high-end ERP system the must-have addition to pharmaceutical companies’ operational management strategy. Pharma companies need to chalk down their unique challenges and requirements and then invest in a comprehensive ERP tool to fulfill those needs.

In a complex and dynamic digital canvas, pharmaceutical companies are navigating their way towards efficient end-to-end operations management with the latest tools and technologies.

Key Takeaways

- The challenges in end-to-end operations management are not new to the pharma sector, however, the recent Covid-19 pandemic has made these matters even more pressing.

- Integration of tools and technologies that can optimize and aid in enhancing process efficiencies are must-haves for the pharma manufacturers.

- A comprehensive and systematic ERP tool can prove to be the game-changer in pharma and life sciences operations management.

Start Your Digital Transformation Journey with Assessment