Introduction

The term “bioeconomy” has begun gaining steam but many executives don’t know what it means or how it might affect their business.

Brain-biotech.com defines bioeconomy as producing renewable biological resources and then converting them plus waste streams into valued-added products. These include food, animal feed, bio-based products and energy, including fuels.

A related but different concept is the circular economy, “where the value of products, materials and resources is maintained in the economy for as long as possible, and the generation of waste minimized,” the article states.

Both concepts share the goals of increasing resource efficiency and lowering demand for new petroleum resources while creating more jobs. Tying into both of these is “cascading,” which promotes recycling and remanufacturing. An example of cascading is using fresh wood to build furniture. When the main product’s life ends, part or all of the wood is used for something else such as a different piece of furniture or a planter.

“The circular economy includes all kinds of material streams with different utilization routes. Organic recycling, which equals biodegradation, and even the capture and utilization of carbon dioxide from industrial processes or the atmosphere are included,” the report states.

One way the bioeconomy affects industry is by producing renewable carbon compared to fossil carbon such as oil and other fossil fuels. The bioeconomy and circular economy have a common goal: creating a more sustainable world with a low carbon footprint. Both avoid using fossil carbon. Using sustainable resources helps achieve climate targets, brain-biotech states.

Among the stated goals of the bioeconomy and the circular economy are:

- Reducing the use of fossil fuels

- Wiser management of natural resources

- Continually reusing minerals, metals, and biomass from agriculture, forests and the seas

- Creating biodegradable and compostable products

- Generating ways to capture and reuse carbon dioxide in the Carbon Capture and Utilization (CCU) process

- Reducing greenhouse gas emissions such as carbon dioxide (CO2)

- Reducing waste, especially anything going into landfills

- Promoting research across disciplines and borders

- Creating more jobs in rural and urban environments

Impacts of the Bioeconomy on the Financial Economy

Features unique to the bioeconomy include creating new products and better utilization of agriculture and forestry, Brain-biotech states. Among its examples are using genome editing to create products with lower toxicity and new functions plus more nature-compatible (i.e., biodegradable) and healthier consumer goods.

So where can we see the bioeconomy? “The U.S. bioeconomy is all around us: new drugs and diagnostics for improved human health, higher-yielding food crops, emerging biofuels to reduce dependence on oil and biobased chemical intermediaries,” the 2012 White House’s National Bioeconomy Blueprint is quoted as saying in youmatter.world.

Youmatter.world connects the bioeconomy and circular economy by referring to the circular economy as “the what” as in what are desired outcomes. The bioeconomy is “the how” as in how biophysical processes can be enhanced to achieve the expected result.

Transforming the U.S. economy from one based on hydrocarbons (i.e., fossil fuels) to a bioeconomy, will have the most dramatic effects. These effects will be felt most strongly in the energy, agricultural, chemical, industrial and consumer products and transportation industries, attorney Neil Belson wrote in 2016.

Among Belson’s conclusions are, “an economy that runs primarily on renewable, domestically produced bio based raw materials is inherently less vulnerable to disruption than one which relies on or is heavily influenced by the availability of foreign fossil fuel energy supplies.”

Among the biofuel resources are corn stalks and wheat straw, animal manure, household and industrial organic wastes containing carbon and dedicated fast-growing energy crops.

Belson also suggests a major target of opportunity is the $164 billion U.S. organic chemical industry.

By the Numbers

After several years of declining revenue caused by low fossil fuel prices, the Organic Chemical Industry is expected to resume growing in 2021, reports from IBISWorld state. Among the highlights are:

- 13.2%: The 2021 increase in market size estimated by the Organic Chemical Manufacturing Industry (OCMI).

- $106 billion: The 2021 market size measured by revenue of the OCMI

- 1,107: Number of organic chemical businesses in the US

- 75,441: Number of people employed in the organic chemical businesses in the US

Current top products and related manufacturing activities are producing:

- Ethyl alcohol

- Cyclic crudes, coal tar, wood chemical and intermediate products

- Basic organic chemical products

- Fatty acids

- Synthetic organic alcohols

- Synthetic flavor and perfume materials

- Bulk pesticides

This list does not include forestry-related materials such as major wood products.

According to the Government

The US Department of Agriculture released the 128-page “An Economic Impact Analysis of the U.S. Biobased Products Industry” in 2015.

Using 2013 numbers, the US Biobased Products Industry:

- Contributed 4 million jobs

- Added $369 billion to the U.S. economy

- Created 1.64 more jobs for every 1 biobased products job

- 20,000 products in the BioPreferred program database not including traditional textile fabrics or forest products. The true number is closer to 40,000, the report states.

- 300 million gallons of petroleum replaced by biochemicals and natural-based products replacing petroleum products such as Styrofoam.

Get a consultation to learn how to get your company ready for the bioeconomy.

Areas of Opportunity

Figure: 1Number of Installed Ethanol Biorefineries in the US

Statista states that in 2019, the US had more than 200 ethanol biorefineries. In 2015, the USDA listed 213 such refineries. Audi, BMW, Porsche and Volkswagen make diesel vehicles that can use biodiesel blends, edmunds.com states. As of 2014, most biofuel came from soybean oil. The US Department of Energy states that the B20 biodiesel blend contains 2% – 6% biodiesel mixed with petroleum fuel.

Adding biodiesel improves fuel lubricity making vehicles easier to start and reduces ignition delay. It also reduces premature wear on moving parts even in concentrations as low as 1%, the Alternative Fuels Data Center states.

Chemical and pharmaceutical companies, take note: Modor Intelligence estimates the market for biochemical reagents will grow at a CAGR rate of 9.1% between 2020 – 2025. This market is defined by products such as cell and tissue reagents, electrophoresis and others plus geography. Asia Pacific is the fastest growing market while North America is the largest.

Chromatography reagents have the greatest demand with their use in many pharmaceutical processes such as separating chemicals and biomolecules, diagnostics and protein purification.

Market Research Future’s report on the Global Bio-Based Chemicals Market states the top products between 2019 – 2025 will be bioplastics, bio-lubricants, bio-solvents, bio-based acids, bio-surfactants, bio-alcohols and others.

Let Technology Help

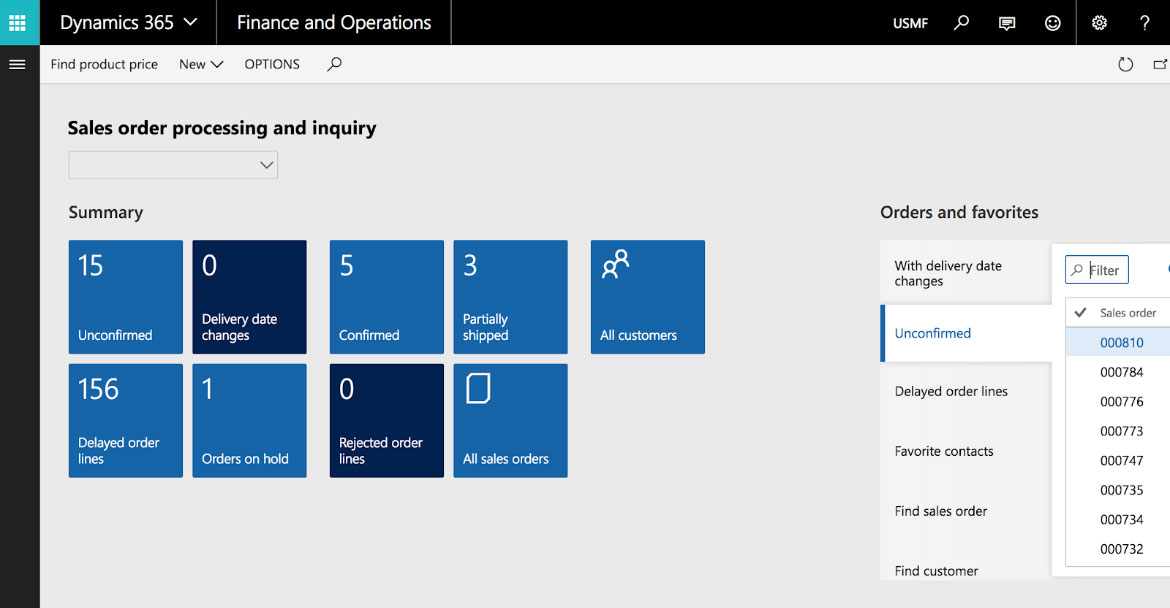

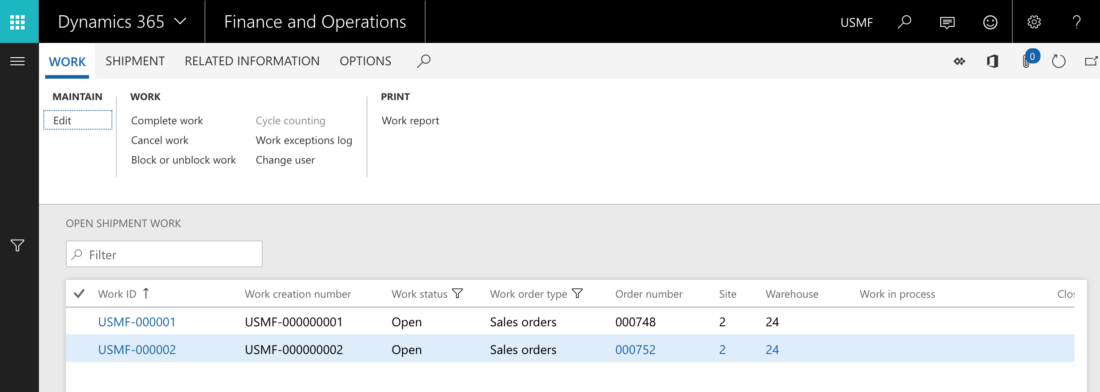

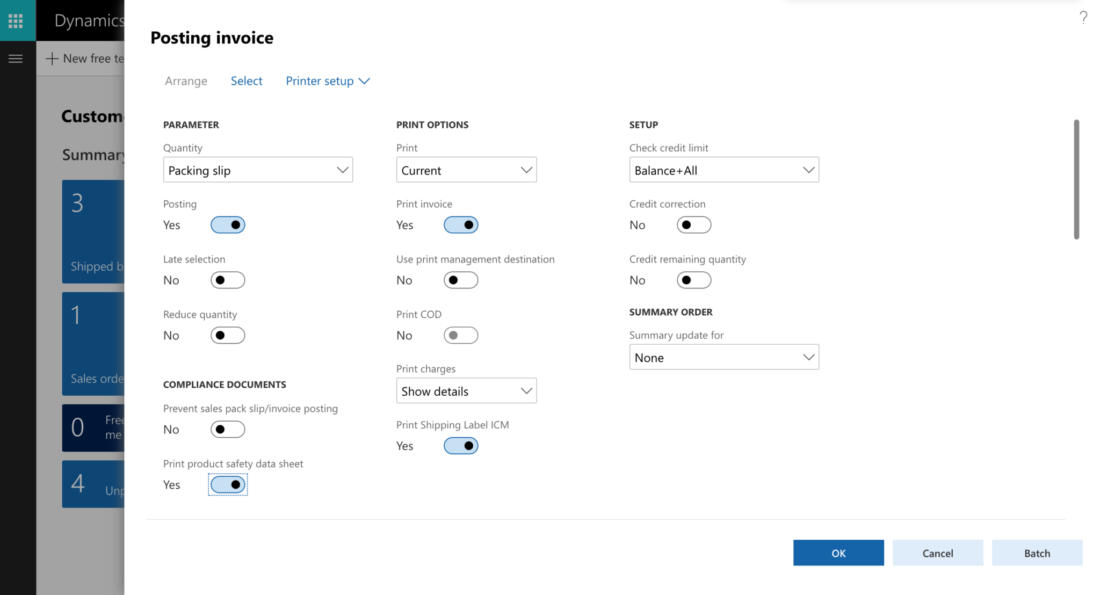

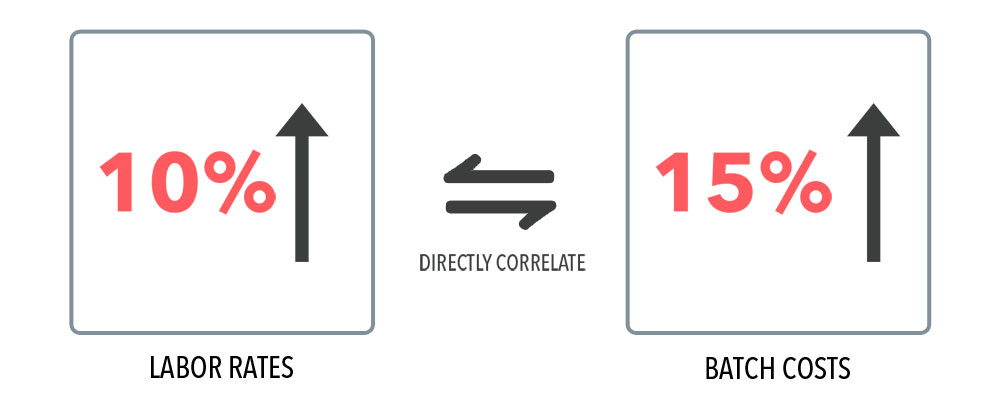

What chemical wastes currently costing the company money to be shipped to a landfill can be reused to boost profits? Companies using technology like Microsoft PowerBi and Microsoft Dynamics 365 to organize their data can organize waste into its core components. Some of it might be easily converted into biofuels. Others might be broken apart with components becoming biodegradable solvents.

Another way tech can help is by looking at existing customers in growing markets and suppliers in areas where key crops are grown. Are they ways to piggyback shipments and reduce transportation costs while also cutting air pollution? Microsoft Dynamics 365 Supply Chain Management can combine and crunch data. While helping a business run much more efficiently, it can also offer insights into new ways to use existing products.

The Bottom Line

The bioeconomy is here to stay, as is global warming. Companies entering bioeconomy markets should look at new ways to use plant-based materials to replace petroleum products, like the chemical and pharmaceutical industries using plant-based solvents to develop new medicines because they are less toxic and better for everyone in the long run.

Alternate fuels, fibers, chemicals made from plants and other biological sources are just a few of the many potential products whose demand will continue to rise.

Using cutting-edge enterprise resource planning software can help a company more accurately evaluate its own products and resources. Who knows, there just might be the materials to build some bioeconomy products already sitting on a warehouse shelf. With the right tech, you will know what you have.