Microsoft Dynamics

Transformation

Starts Here

Microsoft 365

End to end business applications for small to large enterprises, designed to deliver maximum value

Microsoft Dynamics 365

A set of intelligent business applications that helps you run your entire business and deliver greater results through predictive, AI-driven insights.

Microsoft Azure

An ever-expanding set of cloud services designed to help your organization meet your business challenges with the freedom to build, manage, and deploy applications on a massive, global network using your favorite tools and frameworks.

Our Focus Areas

Microsoft Dynamics 365 Sales

Find and build stronger relationships. Improve productivity and performance. Get a single view of your customers.

Microsoft Dynamics 365 Finance

Automate and modernize your global financial operations with Dynamics 365 Finance.

Microsoft Dynamics 365 Supply Chain (Operations)

Transform your manufacturing and supply chain operations with Dynamics 365 Supply Chain Management. Use predictive intelligence from AI and Internet of Things (IoT) as an add-on.

Microsoft Office 365

Designed to help you achieve more with innovative Office apps, intelligent cloud services, and world-class security.

Office 365 is now Microsoft 365.

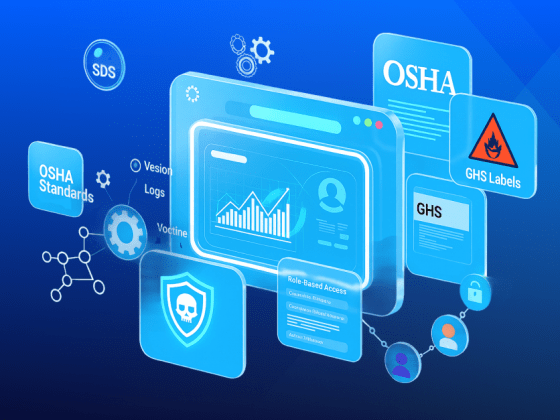

Integrated Chemical Management (iCM)

An industry-first integrated solution for Microsoft Dynamics that offers comprehensive functionality for chemical.

Microsoft Dynamics 365 Marketing

Increase customer demand for your products and services, create seamless customer experiences, and improve marketing results with Microsoft Dynamics 365 Marketing.

MICROSOFT’S End-to-end intelligent business applications

our strength

Identifying the

right

technology

- Technology can be a disruptor, driving innovation and helping your business become more efficient, productive, and competitive.

- Customers are rating your business on technology you use and the ability to integrate with their processes and supply-chain.

- Markets now demand a rapid adoption to change and your technology stack dictates how well you can adjust to continual transformation.

- Organizational growth is stunted by fear of change, or having to update old SOPs, new technology and more. Building a culture of innovation and a workforce that is technology-minded is all you need to move forward.

MAKE SMARTER DECISIONS TODAY

Work with XcelPros today to setup a risk-free Pilot Program to help achieve your end goals and protect your investment.

1 Week No-Obligation Pilot

Experience Our Industry and Product Expertise First-Hand

HELPING OUR CUSTOMERS COPE WITH THE NEW NORMAL

Covid-19 has been a challenge for most companies. To help our customers cope with the new normal, we are offering 1 week no-obligation pilot.

Next Steps

Our InsightsSee All

How to Manage Supply Chain Disruptions: Causes and Impacts

How to Manage Supply Chain Disruptions: Causes and Impacts https://xcelpros.com/wp-content/uploads/2021/11/How-to-Manage-Supply-Chain-disruptions-card-thumbnail.png 1108 1008 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gPost COVID19, most sales and marketing teams have gone remote. The unforeseen circumstances of not having an in-person interaction with customers have driven businesses to invest in the latest and conversion-oriented CRM tools.

How technology helps in optimizing the Pharmaceutical supply chain

How technology helps in optimizing the Pharmaceutical supply chain https://xcelpros.com/wp-content/uploads/2025/12/pharmaceutical-supply-chain-role-of-technology-right.jpg 1500 1071 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gThe inability to adapt to technological advancements and rapidly changing regulatory landscape makes managing pharmaceutical supply chains quite a tough pill to swallow. Successful pharmaceutical companies leverage the power of IT to streamline their supply chain operations.

On-Time Delivery (OTD) KPI Your Most Important Metric In Operations Management

On-Time Delivery (OTD) KPI Your Most Important Metric In Operations Management https://xcelpros.com/wp-content/uploads/2019/01/on-time-delivery-in-operations-part-2-banner-right.jpg 800 571 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gAt a Glance: Why On-Time Delivery (OTD) Matters According to Harvard Business Review research, increasing customer retention rates by just 5% can increase profits by 25% to 95%, highlighting the critical importance of meeting customer demands on time. A 2024 industry report showed that 69% of consumers are less likely to shop with a retailer…

Batch Traceability in Pharmaceutical Manufacturing

Batch Traceability in Pharmaceutical Manufacturing https://xcelpros.com/wp-content/uploads/2025/10/batch-traceability-in-pharmaceutical-manufacturing-right.png 950 627 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gThe pharmaceutical industry has faced many challenges. One of the biggest challenge is how to address batch traceability when it comes to pharmaceutical manufacturing.

Streamline Your Supply Chain with Advanced Warehouse Management System

Streamline Your Supply Chain with Advanced Warehouse Management System https://xcelpros.com/wp-content/uploads/2025/10/streamline-your-supply-chain-with-advanced-warehouse-management-system-right-final.jpg 950 627 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gDiscover the capabilities that D365 Advanced Warehouse Management brings to the table to address key warehouse management challenges.

Pharmaceutical Manufacturing Cost Breakdown: Why It Matters

Pharmaceutical Manufacturing Cost Breakdown: Why It Matters https://xcelpros.com/wp-content/uploads/2021/09/pharmaceutical-manufacturing-cost-breakdown-right.jpeg 800 528 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gForecasters are projecting more opportunities for mid-market pharmaceutical companies operating in the US. These opportunities will require more streamlined processes within pharmaceutical manufacturing and contract development and manufacturing organizations (CMOs and CDMOs).

Cybersecurity Compliance in Chemical Plants: Managing Rising Risks

Cybersecurity Compliance in Chemical Plants: Managing Rising Risks https://xcelpros.com/wp-content/uploads/2025/09/cybersecurity-compliance-in-chemical-plants-right-img.png 950 627 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gDigital security threats are increasingly targeting industries—including the chemical sector—to the point the Department of Homeland Security is now issuing cyberterrorism guidelines.

Managing Chemical Compliance With ERP: OSHA to GHS

Managing Chemical Compliance With ERP: OSHA to GHS https://xcelpros.com/wp-content/uploads/2025/09/managing-chemical-compliance-with-erp-osha-to-ghs-right.png 950 627 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gWhen used effectively, modern enterprise resource planning software (ERP) can help companies in several ways when it comes to chemical regulations

How Technology is Solving Pharmaceutical Compliance Risks in 2025

How Technology is Solving Pharmaceutical Compliance Risks in 2025 https://xcelpros.com/wp-content/uploads/2025/09/how-technology-is-solving-pharmaceutical-compliance-risks-in-2025-right.png 950 627 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gMany pharmaceutical companies have restructured their financial and resource allocation models to invest more in adhering to compliance. Compliance requirements around the globe have grown in past decades.

Audit Readiness in Pharma: From Scrutiny to Systemic Strength

Audit Readiness in Pharma: From Scrutiny to Systemic Strength https://xcelpros.com/wp-content/uploads/2021/01/828blogbannerRight.png 950 658 Xcelpros Team https://secure.gravatar.com/avatar/eb2f8c285d005e0a1f2e0e90930b154a89fb9ffee085d55d1ee27cf29815eff7?s=96&d=mm&r=gThe pharmaceutical market has faced various challenges during COVID-19, including a complex set of regulatory standards. Due to the stringent FDA pharmaceutical regulations, pharma companies always need to keep up with managing compliance tools.