Introduction

Even today, Covid-19 continues to disrupt every level in supply chains, across every industry around the world. The lasting effects on supply chains was unanticipated, especially concerning food and cleaning supplies. Manufacturers in those areas had an unexpected spike in demand that couldn’t be managed quickly.

The overall supply chain disruption caused many companies to start re-evaluating action plans. Areas being closely examined today include production capacity, cash flow and overall employee morale.

Let’s look at how businesses can leverage existing practices while pivoting to newer methods and meeting evolving customer needs.

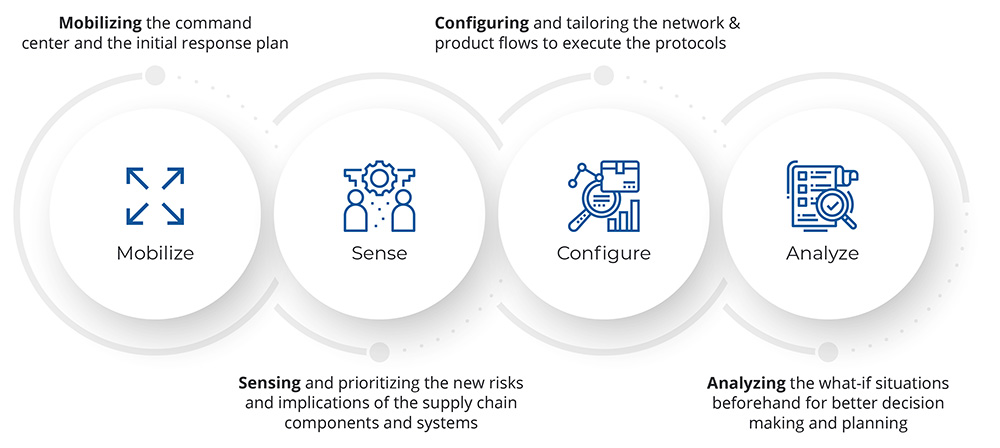

Figure: 1Surviving the Supply Chain with a Digital and Analytical Backbone

Communication and Collaboration

The first quarter of 2020 brought new dynamics to manufacturers and distributors everywhere, faced with a challenge the likes of which have never been seen before. As market dynamics changed, internal communication became critical at every stakeholder level: management, employees, customers, suppliers and vendors. Creating a communication strategy that could work when people stopped meeting face to face became vital to avoid business breakdowns and shutdowns.

That was 2020. The lingering effects of Covid-19 are still impacting some companies’ technology roadmap plans. However, there are ways to drive innovation and growth. Regardless of industry, many organizations realize the importance of doing business from anywhere. That flexibility to work on the move is no longer a luxury: it is a necessity. Unconventional work schedules are becoming more common as companies adjust to meet customer expectations. Companies are engaging them with messaging and video call software such as Microsoft Teams. They use software such as Power Automate to deploy safety alert messages whenever the need arises.

Customer and vendor portals equipped with Microsoft Dynamics 365 Supply Chain Management let companies collaborate, determine product access and make accurate forecasts without having to pick up the phone. Instead of days or weeks of delays, modern software helps firms resolve supply chain disruptions at a moment’s notice.

Manufacturers using Microsoft Dynamics 365 Supply Chain Management can integrate Internet of Things (IoT)-enabled devices and robots into their current operations. Using machine learning adds even more automation.

Connecting data and processes with Microsoft’s wide selection of products allows production and maintenance teams to schedule downtime when it has the least impact on production. Outlook messages and alerts let production staff stay on top of any possible repair issues.

Book a assessment to know how to make your supply chain a resilient one.

Agile decision making

Manufacturers must respond to the rapid changes in customer demands and delivery expectations. Having a robust system lets that happen.

Changes to your customers’ business demands can affect your supply chain. Having the ability to act quickly while still providing exceptional customer service is critical to future business success.

One way to prepare for these changes is by having internal cross-functional teams practice scenario planning. For example, they can plan what to do if a new Covid-19 variant appears and governments reinstate drastic safety measures.

Scenario planning lets your staff learn what to do when normal deliveries are delayed or rerouted, such as what happened when the Suez Canal was blocked for a week. It lets your staff examine past customer and supplier behaviors and come up with plans to minimize disruptions using what they learned.

Microsoft Dynamics 365 Supply Chain Management includes tools designed specifically for scenario planning. It helps companies adjust to unexpected changes in their supply chains. These tools include:

- Drag and drop Gantt charts for production scheduling

- 360 degree view into capacity, identifying bottlenecks in terms of people and resources

- Adjusting safety stock to reflect real-time demands instead of fixed quantities

- A vendor portal with approved suppliers listed in a supplier resource management database that includes purchase order controls

- Visibility into warehouse operations for single and multi-site facilities

- Transportation management

- A customer portal with sales order management

Incorporating Data

Data in today’s operations is a moving target. Making decisions and providing insights with real-time information helps companies operate efficiently, letting them grow and scale at the right times. Identifying organizational segments that require optimizing, like the handoffs between operations and finance, can only occur when accurate information is available.

For example, the only way to truly analyze cash flow—to get a 360-degree view—is by looking at data within each division.

This is where a business analysis tool like Power BI becomes an essential part of the process. Power BI dashboards using predictive analytics in the Dynamics 365 environment automatically update with the latest data. These dashboards let companies monitor the status of multiple locations at once, saving time.

Tools such as Power BI let management share data, communicate and respond to changes in the market within minutes, not days.

Final thoughts

The coronavirus is the first disruption of its kind faced by this generation. Companies were caught unprepared, being forced to adjust almost instantly to upheavals in their supply chains. Having the right tools in place to deal with Reduced workforces internally and within the supply chain, pivoting production to new products and unprecedented customer product demand helps determine who flourishes and who fails.

With that in mind, it’s critical to consider implementing products from Microsoft’s family of partner solutions. Dynamics 365 and related products help companies predict and manage their operations transparently.

References: Why the Pandemic Has Disrupted Supply Chains