At a Glance

- Chemical companies are reeling under a two-edged crisis- unprecedented fall in the price of crude oil and the upheaval brought in the global supply chain because of Covid-19.

- Chemical companies have also faced issues like increased freight costs, excessive demand for chemical sanitizers, and changing government regulations across different geographies.

- Mitigating costs, managing inventories, avoiding bottlenecks and rising to the challenges would be some of the top-most priorities of the executives managing chemical transportation and logistics.

Global supply chains have seen direct and ripple effects of the coronavirus or Covid-19 pandemic. The pandemic has caused operational upheavals and seen acute disturbances in logistics due to shortage of chemical raw material. Adapting to volatile market conditions in the face of a challenge shows the company’s ability to sustain growth. Determination, planning and willingness to adapt to changes are expected from the rapidly growing chemical companies.

To aid with their business continuity plans, chemical companies need to continue to reinvent their operational processes, inventory management strategies and transportation management. Supply chain challenges in the chemical industry are inevitable as every country responds differently to health and economic crises. A crisis changes the way you manage inventory, raw material procurement, monitor demand for certain chemicals, workforce procedures, freight costs, etc.

23%

of the USA’s chemical companies considered supply chain disruptions due to the coronavirus pandemic as their major concern for the coming future.

Source: PWC

Many comprehensive software applications have been developed to provide concrete solutions to mitigate the issues related to supply chain disruptions. Microsoft Dynamics 365 Supply Chain Management has been cited as the best software for supply chain management and a complete solution for distribution and logistics. Here are four primary concerns that chemical companies are facing when it comes to managing transportation and logistics:

1.Moving to Road and Railways: Transportation and logistics in the chemical industry have been heavily dependent on airways and waterways in bigger countries and across international borders. However, increased safety concerns and inflated costs make chemical companies shift to the transportation of raw material, and final products through roads and railways. The change in mode of transportation directly impacts the landing cost of the product. Inability to track accurate landing costs, end-to-end transportation tracking and scheduling are some major pain points in a chemical company.

2.On-time Delivery of Raw Material: There is a sudden and unexpected disparity in the demand for different chemicals. Demand for chemical surface cleaners, sanitizers has increased several folds across the globe (and understandably so), however majority of challenges are related to on-time delivery of material. Unpredictable transportation lead times and inability to deliver these raw materials is a big pain point in providing accurate receipt dates.

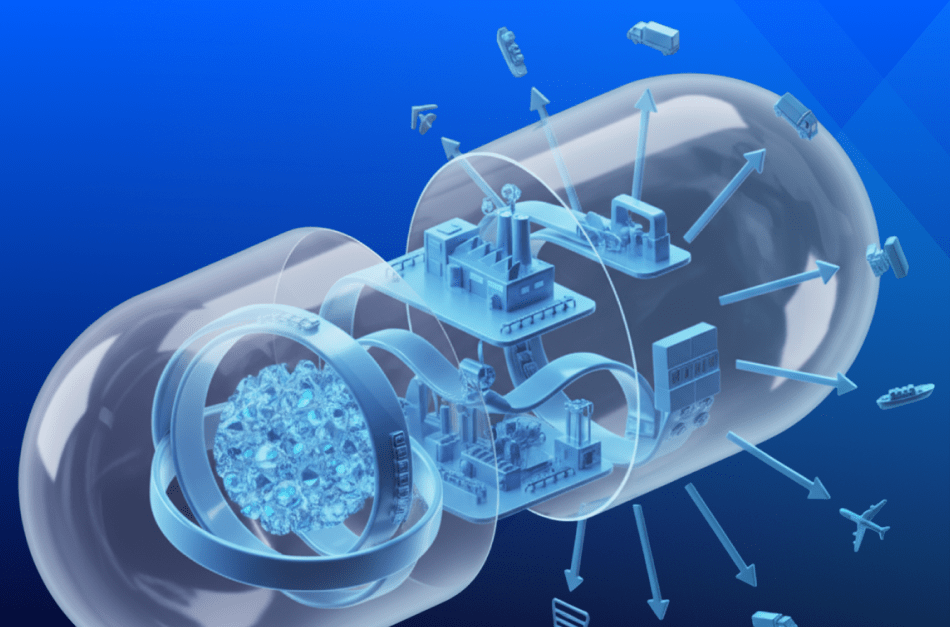

Figure: 1 High-level Disruptions in Chemical Transportation due to Covid-19 Pandemic

3.Transportation Planning and Inventory Management: A supply chain can run smoothly only when the inventories are managed well. Given the current times, chemical companies need to align their requirements and logistical arrangements with the availability of products in their respective inventories. This requires top-to-bottom visibility and high-level decision making to approve faster changes in material requirements. A major roadblock is related inefficient transportation planning to minimize delays.

4.Increased Freight Cost and Changing Regulations: With change in modes of transportation, and disruption of demand and supply pattern of chemicals worldwide, freight cost shot up by several times. Chemical companies have to deal with higher freight costs along with issues in logistics and supply chain management.

Despite all these pain points, chemical companies can reinvent their transportation and logistics operations to rise to the occasion. Here are certain measures that chemical companies can take to streamline their distribution demands:

- Assessing the requirement based on geographies and allocating warehouses to meet those demands.

- Labeling, stocking and categorizing chemical stock based on order priority and making them easily available for transportation.

- Making use of serialization and bulk containers with barcodes for optimal supply and efficient tracking.

- Appointing a special task force to manage transportation and logistics changes to optimize the supply chain and provide the single-point contact/ visibility option to all the stakeholders involved.

How Can Your Chemical Company Optimize Transportation and Logistics Operations Using Microsoft Dynamics

Microsoft Dynamics 365 provides the right features for a chemical company to manage operations, inventory and transportation. Once you get the view of your company’s transportation and chemical supply chain management in Microsoft Dynamics 365, you will be able to plan and implement optimization strategies for chemical transportation and logistics.

The information about chemicals are required to be maintained and tracked under high-level categories. Also, labeling batches, mentioning hazardous substances, barcoding containers and mentioning chemical properties is part of any chemical company’s logistics plan in Microsoft Dynamics 365 in conjunction with integrated chemical management.

Microsoft Dynamics 365 allows for complete inventory visibility through its Distributed Order Management (DOM) indicator. This allows all the stakeholders to stay on top of things, avoid bottle-necks or stock-outs during these unprecedented times.

Chemical companies can benefit from comprehensive Transportation Management module in Dynamics 365. The module is loaded with features that can let you manage your transportation and logistics while also letting you identify vendor and routing solutions for inbound and outbound orders. In these times of extreme price inflations and changing market dynamics, this module helps your chemical company cut operational costs in logistics by effectively planning inbound and outbound transportation. Highly advanced business intelligence built in the Dynamics 365 Transportation Management module helps chemical companies identify best-priced and most efficient carriers. Through this module, you can get real-time visibility of the entire order at all times.

Here are some of the most impactful benefits of Microsoft Dynamics 365 Transportation Management module for chemical companies:

- Warehouse Management Efficiency

- Enhanced Delivery Capabilities

- Inventory Reductions

- Real-time Supply Chain Visibility

- Effective Customer Service

- Set up Ad-hoc Cycle Counting Thresholds and Cycle Count Locations

- Pre-schedule Route Planning for Efficient Transportation

- Availability of Multi-packing Slips in Load Planning

- Skip Trivial Freight Reconciliation Process

Every chemical company has a different shop-floor operation and needs customized production operations plans for kits and packaging (for transportation). This option is easily accessible with Microsoft Dynamics 365.

Companies can manage lot tracking, tracing of chemicals, route mapping, resource availability, and freight cost management. The system provides the option of generating individual or batch invoices.

The Transportation Management module in Dynamics 365 follows a well-vetted process flow that is dynamic and customizable, based on your transportation requirements.

Figure: 2Transportation Management Process Flow in Dynamics 365

While it is true that the world is witnessing changes in the chemical supply chain and transportation due to the Covid-19 pandemic, companies can rise to the occasion with resilience, optimal use of resources and a systematic approach towards change in processes. There is a need for continuous innovation to stay ahead of the chemical companies’ curve to continue operations during this ‘new normal’.

Key Takeaways

- Transportation and logistics of chemical companies are facing the ripple effects of disruption in global supply chain caused by the coronavirus pandemic.

- While there are many challenges, chemical companies will need to reinvent their transportation management with the help of intelligent applications like Microsoft Dynamics 365. Once operations and processes are efficient, chemical companies can improve their transportation planning to ensure on-time delivery.

Reach out to us for your company’s Digital transformation.