At a Glance

Recovery by end-use markets and export consumers are expected to boost the U.S. Chemical industry in 2021 and 2022. The American Chemistry Council (ACC) predictions include:

- A global gross domestic product (GDP) increase of 6.1% in 2021 and 4.4% in 2022

- A rise in the U.S. GDP of 6.4% in 2021 and 4.3% in 2022 after a 3.5% fall in 2020

- U.S chemical volumes will increase by 1.4% in 2021 and 3.2% in 2022

- Chemical shipments will increase 8.1% in 2021 and 8.2% in 2022 after a 13.5% decrease in 2020

- Capital spending will increase 11.9% to $30.6 billion in 2021 and 3.1% in 2022 after falling 17.6% in 2020

- Basic chemical production will rise 0.5% in 2021 and 3.4% in 2022

- Specialty chemicals will expand by 3.8% in 2021 and 4.1% in 2022 after falling 10.8% in 2020

- Chemical exports will rise 5.8% in 2021 and 13.2% in 2022 after falling 7.6% in 2020

- U.S. Chemical imports will rise 1.7% in 2021 and 13.7% in 2022 after falling 5.1% in 2020

Also affecting U.S. chemical companies are tariffs and regulations.

- U.S. tariffs on Chinese goods were averaging 19.3% on a trade-weighted basis in early 2021, up dramatically from the 3.8% rate before the U.S. China trade war, CNBC states

- China currently has a 20.7% tariff on U.S. goods

- Failure to meet global harmonized system (GHS) labelling requirements can generate fines of $12,600 per violation and up to $127,000 per violation for the most serious issues

Making Sense of the Numbers

Higher production translates to higher capacity requiring production managers to equip themselves with the technology needed to adapt to the changing market.

A sophisticated enterprise resource planning (ERP) business application helps plant production managers keep up with rapidly changing challenges. ERP software also lets them track key metrics such as inventory turnover and manufacturing throughput to optimize cost of production.

Production in modern-day chemical companies involves unforeseen challenges. These range from obtaining raw materials to ensuring proper quality, fluctuating demand, tariffs, dwindling margins, capacity and resource planning. It also requires keeping formulas secure from data thieves.

Regulatory compliance plus international tariffs add additional stress to profit margins and the supply chain.

Tariffs require leveraging resources more efficiently to achieve better margins while promoting trade. One effect is forcing companies to explore near-shore vendors that can supply essential materials at a reasonable price.

One way to become more efficient is by using modern technology. ERP solutions such as Microsoft Dynamics 365 (D365) Business Central have tools that let production managers take more control of their production floor.

For example, production scheduling is complex, requiring an understanding and balancing of specific elements such as:

- Resources Planning

- Continuous production

- Optimal asset planning

- Fluctuating demand

- Tighter lead time

- Procurement delays

- Outages

- Quality check

- Recalls and regulation requirement

Five Key Concerns

Five key concerns for chemical production plant managers are:

- 1.Fluctuating product demands

- 2.Volatility in raw materials supplies

- 3.Complying with government regulations

- 4.Ensuring consistent quality

- 5.Resource and production throughput

Fluctuating Customer Demands

Capital spending will increase 11.9% to $30.6 billion in 2021 and rise another 3.1% in 2022 after falling 17.6% in 2020, American Chemistry Council states.

Basic chemical production will rise 0.5% in 2021 and 3.4% in 2022. Specialty chemicals will expand by 3.8% in 2021 and 4.1% in 2022 after falling 10.8% in 2020.

“Following the worst downturn since the 1930s, the world economy is on the rebound,” Kevin Swift, chief economist at ACC is quoted as saying. “We expect recovery to proceed apace despite multiple risks and uncertainties. These include supply chain constraints and increased demand as economies reopen; trade tensions; weather events, cybersecurity and similar shocks; inflation; financial volatility and public and private sector debt.”

While these developments position chemical companies in a bright spot compared to 2020, not all is bullish. As demand for chemical products increases, so does competition and the demand for innovative products. Production Managers now handle unprecedented customer demands causing tight deadlines and highly-stressed resources.

Production Managers need an air-tight strategy to meet sporadic demands and ensure business continuity. Products such as D365 Business Central are equipped to handle such strategies, ensure complete visibility, provide control over the entire supply chain and support informed decision-making.

Some of the critical elements in production planning and control include Master Planning, Production Scheduling and Production Control as shown below.

Today we live in an on-demand economy. Production managers face rapid changes and increased sales order quantities from customers, adding pressure on Production.

Example #1: A Chemical Plant

Using a chemical plant as an example, say Customer A doubles their order quantity from 5,000 to 10,000 pounds.

To meet this demand, the production manager must respond quickly by evaluating available resources and scale batch sizes in the reactor.

Companies using a modern, well-designed order management system can update the sales order quantity and set the order priority to high.

Order priority can be designed to consider critical demand, customer categories and customer relationships. Changing the order priority signals the materials requirement planning (MRP) system. It issues an updated production order to reflect the larger batch size.

After seeing the revised production order, the production supervisor can review the production schedule and adjust resources to meet the customer’s new demand.

Similar situations are common at chemical companies. Plant managers recognize the need for an integrated ERP system that seamlessly manages communication between different business areas.

Using Gantt Charts

The production control module within Microsoft Dynamics 365 Supply Chain Management creates powerful Gantt Charts. These charts visually represent production flows, map resources, check on material availability and inventories plus see which machines are available. This information helps managers control and optimize the production plan and make informed decisions.

Gantt charts within Dynamics 365 Finance provide a uniform view of schedule activities within a defined time interval. Managers can use these charts to:

- 1.Schedule jobs from production orders. Managers and schedulers can modify production plans by dragging and dropping or using an online menu.

- 2.Schedule jobs from planned production orders. Scheduling starts after the production plan converts to an actual order.

- 3.See hourly schedules of all jobs. A calendar that has active working times is a prerequisite for all production activities. Seeing the real-time status of every job lets managers know the status of “jobs that have started” and “jobs that have ended.”

- 4.View production orders organized by order and resources. Production managers get a real-time view of a production schedule displaying scheduled production orders, material availability and resource capacity. Managers can change schedules when required.

View of the resources available or engaged.–

Volatility in raw materials supplies

Chemical manufacturers use crude oil and natural gas byproducts as the base for their products, accounting for about 50% of the production cost. Oil and gas are extremely volatile commodities with pricing subject to many macroeconomic factors beyond the chemical companies’ control. Volatility causes include geopolitical unrest, OPEC member nation policies, sanctions, currency fluctuation, etc.

Keeping track of raw material cost and availability—especially with the continuing pandemic—is another important production manager function. In the “old days,” managers used a series of Microsoft Excel spreadsheets to manually keep track of key metrics such as inventory turnover and manufacturing throughput. Modern ERPs track data real-time offering benefits to help minimize the effect of raw material price fluctuations:

- Transparently tracking actual costs while accounting for cost of goods sold, revenue, margins, cash flow, etc.

- Adjusting for currency fluctuations when dealing internationally. Managers can obtain materials from the lowest cost supplier.

- Analyzing order volumes and budgeting for cost. Managers can get better pricing and plan production more efficiently.

Complying with government regulations

Any company working with hazardous chemicals is regulated at the federal and state levels. Many also face scrutiny from local officials.

Common requirements are labels meeting GHS standards. Software able to generate the right labels for each product coupled to label printers on the production floor are essential in meeting regulatory requirements.

In the US, companies dealing with hazardous chemicals including manufacturers, distributors, transporters and end-users must adhere to the Globally Harmonized System (GHS) label compliance requirements. Noncompliance can cost $12,600 per violation, while the more serious ones could range up to $127,000, not counting damage to a company’s reputation.

A labeling solution that includes chemical properties, characteristics, batch and lot number, test specifications and other required information is crucial.

Hazardous chemicals need to be distinctly identified to avoid disasters such as when reactive chemicals come in close contact. Labeling applications, such as Integrated Chemical Management (iCM) in D365, can address these issues in Production and elsewhere.

iCM not only provides labels meeting GHS standards, it also includes Safety Data Sheet authoring and management. It reduces human error when printing labels during a production run by knowing which product labels to print during the process.

Ensuring Consistent Quality

The effects of quality checks and recalls can have a long-lasting impact on a company’s reputation. Creating the required documentation for processes such as production, use of raw materials, packaging and others helps track each product from its source to its final destination. Accurate documentation improves visibility in the supply chain and enhances traceability in the event of an inquiry, recall or audit.

Chemicals are used as a base in multiple industries such as automotive, paints, food and beverage, appliance, electronics, packaging, textiles, cosmetics, toys, etc. The graph below shows recalls across major industries in 2016.

A closer look reveals the reasons for such recalls. Top reasons for medical device recalls in the U.S. as of the second quarter, 2019 according to Statista were:

- Software issues (49)

- Mislabeling (32)

- Quality Issues (31)

- Sterility (18)

Common reasons for drug recalls according to WebMD are:

- Health hazards

- Mislabeling or poor packaging

- Poor manufacturing quality

- Packaging and product misalignment

Microsoft Dynamics 365 has the ability to track and trace products at a batch or lot level from the source to the end user. This function helps:

- Ensure regulatory compliance

- Track and trace batches and lots to identify damaged or contaminated products

- Visualize the journey of the product from the manufacturing site to its end-users

- Trace the root cause of an issue and treat it accordingly

Resource and Production Throughput

Managing the production shop floor requires diligent planning of human capital and other interdependent machine resources such as blenders, reactors, mixers, hot ovens, separators, packaging, tanks, etc.

Production planning and scheduling can get overwhelming depending on the number of resources and shifts. Production managers are constantly under pressure to increase production volume using less resources. Recurrent variation in batches to meet higher volume demand and continuous production often results in inconsistent batch quality.

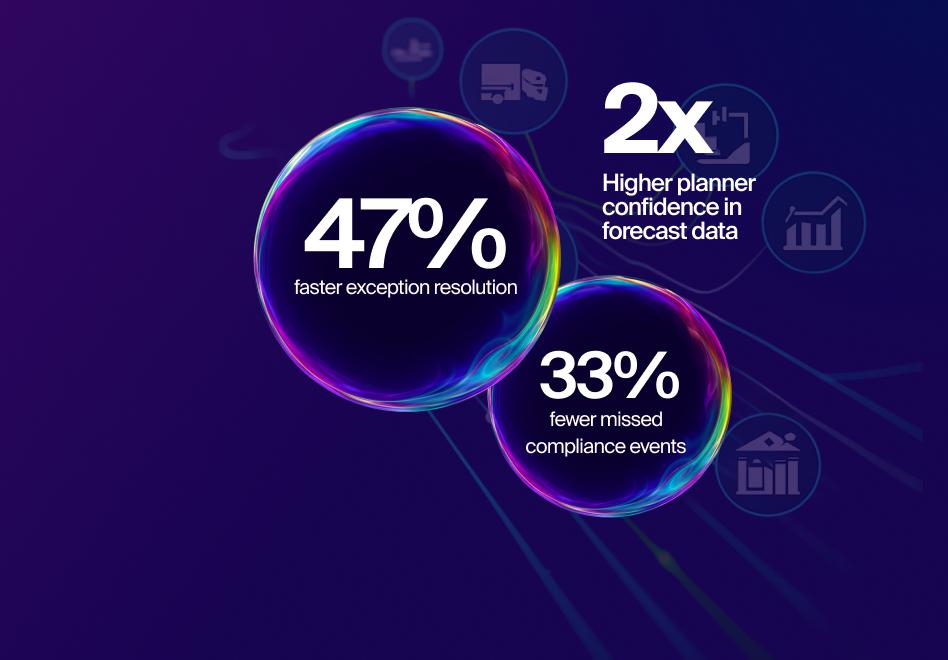

Real-time data monitoring using measured and inferred values can increase production by as much as 4%. D365 uses measured and inferred values to track batch completion in real-time, reducing batch cycle time. It also is also used to achieve batch consistency. Using data collected over time to predict events that can disrupt the production cycle, production managers can reduce those delays, decreasing operating costs.

Being able to track and analyze real-time data also improves asset and resource effectiveness by up to 4%. Unscheduled downtime due to maintenance or breakdown isn’t new to manufacturing plants. Using predictive analytics, past asset performance can model scenarios that detect equipment health and prevent failures.

Key Takeaways

The US Chemical industry is still a volatile market, one that seems to be rebounding from the vagaries of Covid-19 one minute and then being hammered by political crises the next. Individual companies face growing competition to produce unique products, increase production, gain customer loyalty and comply with stringent regulations.

The life of a Production Manager in a chemical industry is stressful. Embracing modern technology will help them achieve company goals while also staying compliant with changing regulations.

Microsoft D365 offers easy-to-use visualization of data across all organizational departments including production, sales, compliance, marketing and others. It’s ability to seamlessly share data across multiple sites and locations enhances transparency and improves product and material tracking and tracing. The combined functions of each D365 application boost productivity and increase efficiency.

Avail a Consultation for to learn how to overcome operational challenges in your chemical company