The chemical industry is a complex and rapidly evolving landscape that requires businesses to stay agile and responsive to market demands. With increasing competition and constantly changing regulations, chemical companies must streamline their operations and optimize their business processes to stay ahead.

Microsoft’s Dynamics 365 gives businesses in the chemical industry a chance to drastically transform their operations and drive growth. In this article, we will explore how Microsoft D365 impacts the business operations of small and large chemical companies.

Improved Inventory Management

Managing inventory effectively can be a big challenge, especially for companies with a wide range of raw materials, finished products, and by-products.

One of inventory management’s biggest challenges is keeping inventory levels accurate and in real time. Without real-time visibility into inventory levels, making informed decisions about when to reorder materials or products can be difficult, resulting in stock-outs or overstocking.

Microsoft’s Dynamics 365 solutions offer robust inventory management capabilities that let chemical companies optimize inventory levels, reduce waste, and improve customer satisfaction. With the ability to track inventory levels in real-time, chemical companies can make more informed decisions about when to reorder materials or products, ensuring they always have the right inventory levels to meet their customers’ needs.

In addition to real-time inventory tracking, D365 offers tools for demand planning and forecasting. By optimizing inventory levels, chemical companies can reduce waste and minimize the need for costly storage facilities, leading to cost savings and increased profitability.

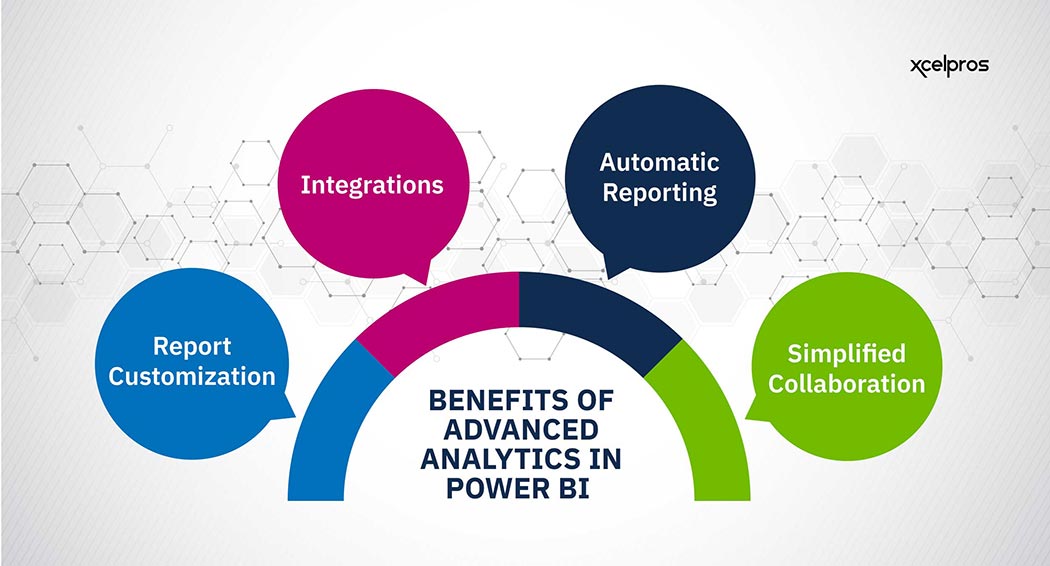

D365 also provides chemical companies with advanced analytics and reporting capabilities, allowing them access to valuable insights into their inventory management practices. With these insights, companies can identify areas for improvement and make data-driven decisions that can help optimize their inventory levels and reduce costs.

Streamlined Supply Chain

The chemical industry is a complex web of suppliers, distributors, and logistics providers. Businesses need to consider the movement of materials and products globally, with multiple stakeholders involved in the process. Managing this complex network can be challenging for chemical companies, particularly in ensuring timely delivery to customers and optimizing supply chain operations.

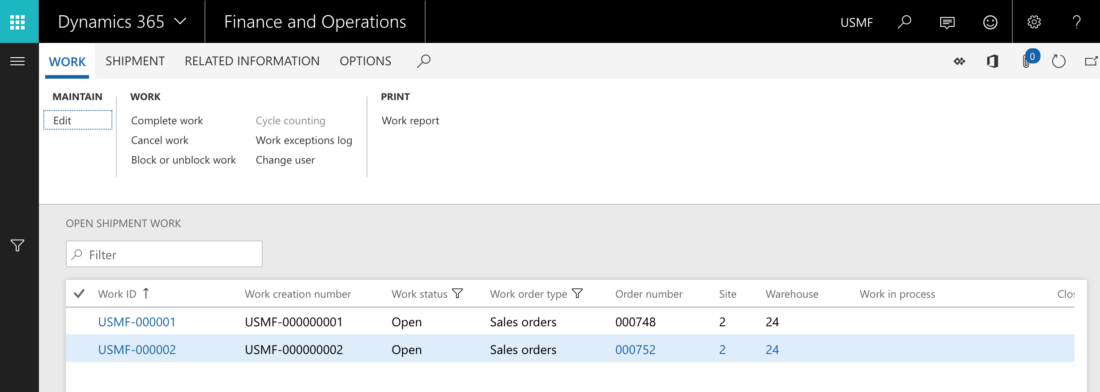

D365 provides a powerful solution to address these challenges. With its supply chain management capabilities, chemical companies can streamline their operations and gain visibility into their entire supply chain. This enables them to make more informed decisions, reduce lead times, and improve on-time delivery to customers.

One of the key benefits of Dynamics is its ability to provide real-time data and analytics about your supply chain. This helps chemical companies identify potential bottlenecks and delays in the supply chain and take proactive steps to address them. For example, they can quickly identify when a supplier is running low on raw materials and take steps to ensure timely replenishment of those materials.

By streamlining their supply chain operations, chemical companies can reduce costs and improve efficiency. They can eliminate manual processes and reduce the risk of errors and delays in the supply chain. This can lead to improved customer satisfaction and increased revenue for the business.

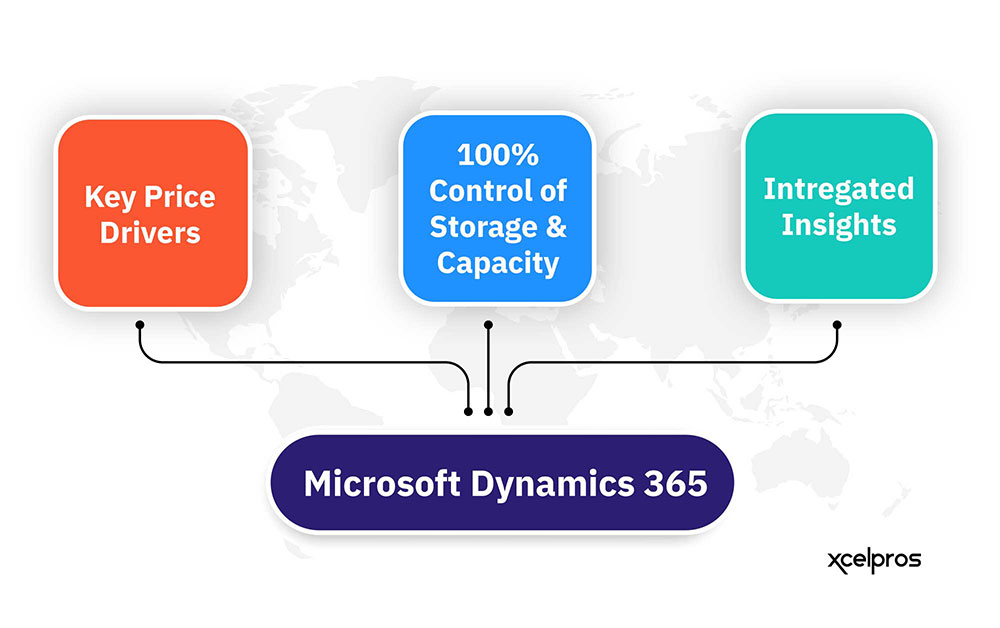

Figure 1:How Microsoft Dynamics 365 helps Chemical Companies

Enhanced Financial Management

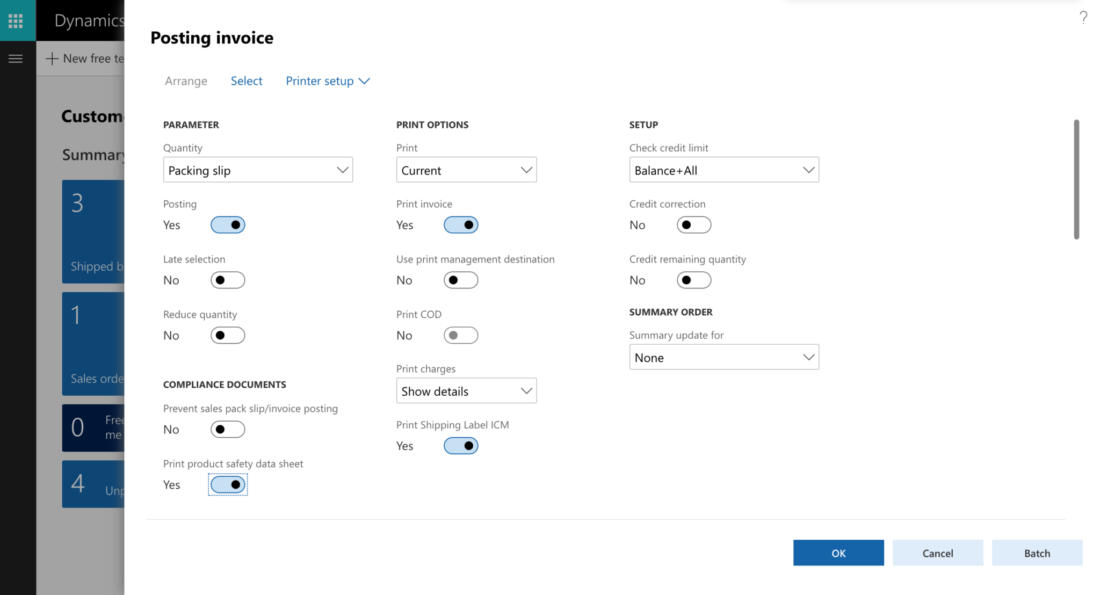

A crucial aspect of any business, financial management is particularly important for chemical companies looking to manage their finances effectively. These companies try their hardest to maintain profitability while complying with various regulations related to the production, storage, and transportation of hazardous chemicals. In this regard, D365 provides a comprehensive financial management solution that enables chemical companies to manage their financial processes more efficiently.

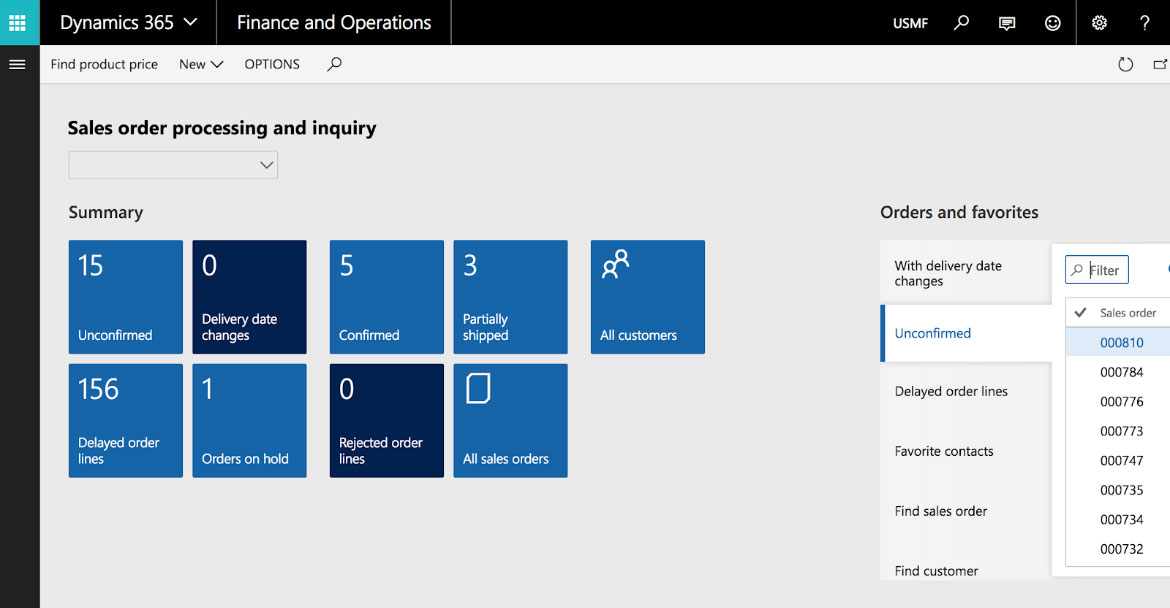

With Dynamics, chemical companies can gain better visibility and control over their finances. They can easily manage budgets, track expenses, and forecast revenue and expenses for more accurate financial planning. The platform provides various financial reporting tools that allow chemical companies to generate detailed financial statements, balance sheets, and cash flow reports.

It also enables chemical companies to manage their accounts payable and receivable more efficiently. Companies can easily create purchase orders, track invoices, and manage supplier payments. They can also manage customer invoices and receive payments online, making tracking outstanding payments easier and improving cash flow.

Improved Compliance and Regulatory Management

The entire chemical industry is under constant pressure to maintain compliance with regulatory bodies at both the national and international levels. Failure to comply with these regulations can lead to significant fines, legal liabilities, and damage to the company’s reputation, making it critical for chemical companies to implement a comprehensive compliance management solution to help them stay compliant with all regulatory requirements.

Microsoft’s solutions provide chemical companies with powerful compliance and regulatory management capabilities. These capabilities enable chemical companies to track and report on regulatory compliance, manage hazardous materials, and maintain compliance with international trade regulations.

One of the biggest benefits of D365 is its ability to track and report on regulatory compliance. With robust compliance management tools, chemical companies can keep track of all relevant regulations and ensure that their operations are fully compliant. This includes tracking regulatory changes, identifying areas of non-compliance, and implementing corrective actions.

Another important aspect of compliance management in the chemical industry is managing hazardous materials. D365 provides chemical companies with tools to effectively manage hazardous materials, including tracking the location of hazardous materials, ensuring proper labeling and packaging, and managing hazardous waste disposal. By managing hazardous materials more effectively, chemical companies can reduce the risk of accidents and ensure compliance with regulatory requirements.

Finally, all chemical companies must maintain compliance with international trade regulations, which can be complex and constantly changing. Microsoft’s solutions allow chemical companies to maintain compliance with these regulations, including managing trade licenses, tracking trade agreements, and managing customs processes. Maintaining compliance with international trade regulations means chemical companies can ensure their operations remain undisrupted so they can continue to serve their customers worldwide.

One Example

A global chemical manufacturing company with several manufacturing sites worldwide faced numerous challenges in managing their complex supply chain and manufacturing operations, including a lack of visibility into production schedules and inventory levels, manual data entry, and inefficient manufacturing processes.

By implementing Microsoft Dynamics 365, the company was able to streamline their business processes and gain real-time visibility into their manufacturing operations. They also used the advanced analytics capabilities of D365 to gain insights into their operations and identify additional areas for improvement.

With D365, the Chemical Company was able to optimize its production planning, reducing lead times by up to 50%. They also reduced inventory levels by up to 20%, resulting in significant cost savings. Additionally, Dynamics enabled the organization to automate several manual processes, saving time and reducing errors.

Overall, the implementation of D365 has significantly impacted the business operations within Chemical Companies, including increased efficiency, reduced costs, and improved customer satisfaction.

One chemical company that implemented Microsoft Dynamics 365 was able to increase its inventory accuracy by 20%, reduce its order processing time by 40%, and improve its on-time delivery rate by 25%.

Conclusion

Implementing Microsoft Dynamics 365 has significantly impacted the business operations of chemical companies. D365 has been helping to revolutionize business operations for chemical industry businesses by providing powerful tools for managing the supply chain, production, inventory, quality control, and financials. With Dynamics, chemical companies can streamline their operations, gain real-time visibility into their business performance, and make data-driven decisions that drive growth and profitability.

At XcelPros, Microsoft Partner. We have a team of experts that can help chemical businesses successfully implement D365 to realize its full potential. We understand the unique needs of the chemical industry and can provide customized solutions tailored to your business requirements. Our team can work with you to define your business requirements, develop a project plan, and provide ongoing support to ensure that your software continues to meet your evolving needs.

Our expertise with D365 lets us help chemical businesses optimize their operations, improve product quality, reduce costs, and increase customer satisfaction. For more information,