At a Glance

- Customer support professionals face constant challenges trying to understand customer requirements while making connections on an emotional level.

- Emotional connections with customers has become an extremely important requirement for companies looking to boost their bottom-line.

- Artificial intelligence (AI) for customer support coupled with machine learning (ML) helps analyze large volumes of customer data using tools like Natural Language Processing (NLP) and advanced voice recognition, to generate.

Introduction

Today’s customers want more affordable, convenient services that cater to their unique needs. Significantly more business is transacted seamlessly across both physical and digital channels. This is a result of increased trust in day-to-day technology which has led to increased sales, along with an easy way for customers to recommend products and services to other people, creating a whole new network of promoters. To take advantage of this change in behaviour, more companies are working harder than ever to deliver better services and provide great end-to-end customer experience.

67%

of customers are willing to switch brands looking for a better customer experience.

Source: Forbes

A lot of brands fail to create a positive emotional experience which directly impacts customer loyalty. This dissatisfaction results in customers switching between brands due to a poor customer experience.

Companies that excel in customer experience can uplift their revenues by 4%-8%.

Understanding this, more companies are beginning to come around to the benefits of investing in AI-automated technologies, with some choosing to focus on boosting their revenue, and others favoring customer experience over price and quality. This doesn’t ignore pricing, but let’s companies place more emphasis on the user experience. Additionally, most of these systems can be automated, further increasing the benefits.

80%

of the customer interactions will be handled by AI eliminating the presence of human agents by 20202

Source: A Gartner Study

Enhancing the customer experience with AI

In a digital world where every minute is important, it doesn’t make sense to have multiple virtual customer service agents set up to manage small issues. Using AI-based solutions to answer simple questions can help control costs to your company along with offering a host of additional benefits such as:

- Providing faster issue resolution

- Answering customer questions 24/7

- Sorting and routing messages

- Ability to transfer to live support as necessary

- Freeing of asset availability to manage high value incidents

This is accomplished by analyzing large volumes of data much faster than a human. AI also uses high-level voice recognition to identify the voices of customers, understand the problem and provide the necessary responses. This all allows for faster prediction of market requirements with much higher accuracy.

Another tool born of AI, Natural Language Processing (NLP), analyses human language to understand context and determine outcomes seamlessly, and often undetected. NLP works in a union with voice recognition to ensure faster problem resolution for customers, reducing frustration. These solutions are deployed as bots and can even be set up to transfer to a human assistant in the event the system is unable to assist. This is important to remember as AI isn’t a replacement for human interaction, just a tool that facilitates an improved experience.

Using AI for enhancing customer experience helps organizations achieve a number of sought after benefits including minimizing pain points, and reducing the number of hours spent by customer agents on simple tasks. AI driven automation with advanced machine learning helps empower your support agents to do their job more efficiently, creating more opportunities for up-sell and cross-sell activities designed to increase sales.

In today’s Age of the Customer, personal, emotive customer interactions play a critical role in bridging the gap for what disruption and digital innovation alone cannot solve. For brands to compete – and win – in CX in 2018 and beyond, service leaders must ensure their teams optimize processes and communication in ways that create positive emotional experiences for customers.

Dennis Fois | CEO of NewVoiceMedia

Harness the power of AI for effective customer services. Get started with a assessment.

Exploring options – How Dynamics 365 can help

Microsoft’s Dynamics 365 Customer Service insights let’s businesses leverage AI-driven insights to improve their customer service experience. Microsoft has included the following innovative features designed to help track performance across various channels

- Dashboard Reference

- Data Subject Rights (DSR) requests under GDPR

The dashboard reference comprises of various dashboards such as –

1.KPI summary dashboard This offers a macro-view of customer service experiences in your company, displaying topics currently generating the highest volume along with emerging issues.

2.New cases dashboard This is an overview of all the newly added customer cases in your system.

3.Resolutions dashboard This is a company-wide view of all case resolutions. AI helps identify the issues that impact resolution time.

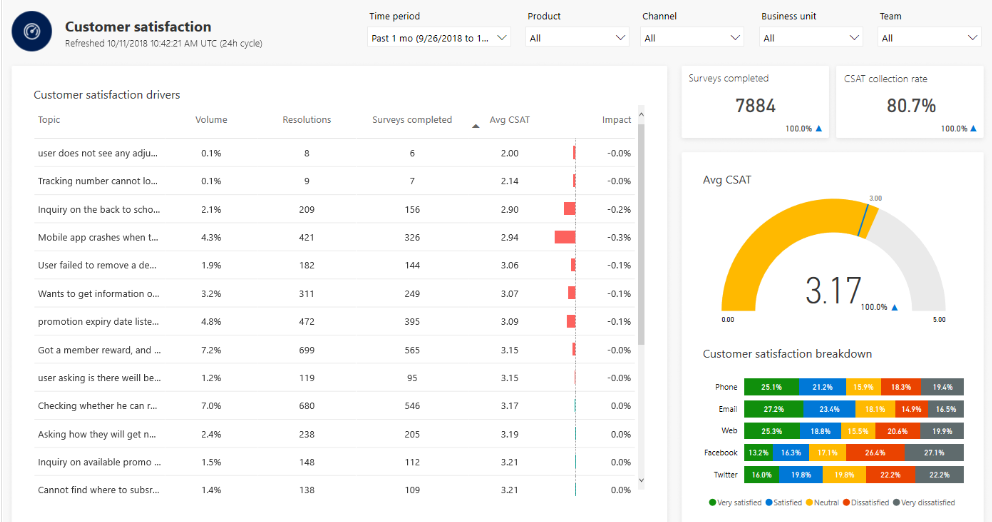

4.Customer satisfaction dashboard Offers an overview of all the customer satisfaction scores in your company using AI automation to track the topics which have the highest impact on CSAT scores.

5.Topic details dashboard This is a detailed overview of key performance indicators(KPIs) for specific topics using AI automation to showcase the impact by product and channel on customer satisfaction scores and resolution time.

Aside from built-in dashboards, visual filters, and interactive charts that give an overview of operational data across all channels, Dynamics 365 also offers actionable insights based on critical performance metrics and emerging trends from your customer service system, highlighting areas that could benefit from improvement and could significantly impact business growth.

Dynamics 365 AI for Customer Service Insights provides a number of valuable benefits including

Improving customer satisfactionBuild brand loyalty by resolving issues before in a timely fashion. Gain a comprehensive understanding of CSAT scores used to calculate customer satisfaction.

Increasing operational efficiencies Streamline operations with insights from case resolutions, historical comparisons, and backlog trends to evaluate customer service agent performance. Monitor case volumes and expected support topics to optimize efficiency.

Enhancing visibility Dynamics 365 helps with effective visualization of customer engagement patterns, customer service operations using various AI-automated dashboards, machine learning capabilities and agent performance, and more. Discover and share critical insights using interactive charts and filters with AI for customer service.

Key Takeaways

While things like sales, pricing and quantity is often the main focus of businesses, it’s important to understand that developing good experiences with customers is just as important, sometimes more. Satisfied customers become extremely effective promoters of the brand simply by recommending your products or services to people they know. This helps businesses expand as loyalty leads to an emotional connection.

As we continue to see newer, more advanced technologies designed to simplify and enhance customer service experiences emerge, understanding the simple fact that people never forget how you made them feel will be even more important. The future of AI in customer service is indeed very bright.

Also Read: Artificial Intelligence in Insurtech : Reshaping the Insurance Industry