Procurement in the Pharmaceutical Industry

The procurement of raw materials in any pharmaceutical company is a source of inventory. An established method to improve visibility, track, and trace product quality is a must-have, regardless if it’s a manual, electronic, or a hybrid purchase-to-pay process. Procurement in the pharmaceutical industry is thoroughly scrutinized, and businesses have become more cautious of raw material and service spending. Many companies are evaluating different suppliers, who can fulfill their requirements at a lower cost, with attention to overall spending and quality requirements.

A robust supply chain management system is needed to:

- manage on hand inventory, and

- build a more reliable end-to-end pharmaceutical supply chain.

What are some considerations when revisiting purchasing functions?

This question shines a light on companies’ need to organize their purchasing process, include more visibility for senior management, and increase traceability of purchasing transactions for streamlining the procurement process. A comprehensive supply chain management solution with low-code and customizable workflows to modernize the pharmaceutical procurement process will be an incredibly valuable asset.

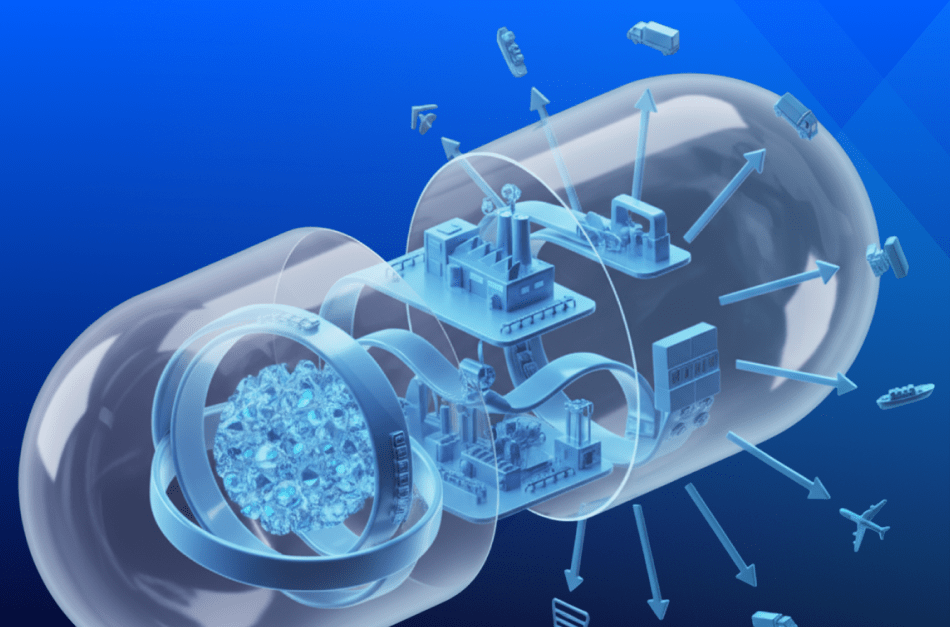

Figure: 1Checklists to Turn Your Supply Chain More Efficient

Businesses can benefit through a supply chain management system with advanced procurement processes to help accomplish the following objectives.

01.Ensure Compliance:

Failure in quality compliance can result in hefty penalties and may jeopardize customer trust, especially when activities, such as buying from approved vendors or segregation of duties between the buyer and invoicer, are compromised. Your procurement management system should provide the ability to perform required audits with controls, and enable only authorized users to perform their appropriate functions. Preferably, a pharmaceutical supply chain management system needs to be in full compliance with 21 CFR part 11.

02.Support Strategic Vision:

Successful life science companies focus on strategic planning and development to boost their bottom line. Any modern supply chain management system should help an organization achieve its strategic goals. Functions like a streamlined buying process are possible with spend analytics, derived from multiple dimensions of purchase transactions. Factors, such as the success rate of higher quality materials from approved suppliers, competitive pricing details, and gauging on time and in full payments from preferred suppliers, are a few key analytics that can help improve decision-making within the purchasing department of the organization to meet their goals.

03.Effective Supplier Relationship Management:

Long-lasting supplier relationships are crucial to procuring higher quality products at the lowest prices. Building a strong relationship with a familiar supplier is far more effective than continually switching vendors to lower costs. Frequently changing suppliers places an additional burden on the entire procurement ecosystem. Suppliers put a lot of effort into understanding your business’ needs over time, including feedback on the quality of raw materials purchased and the speed of shipments delivered, allowing them to make any necessary corrections to their processes. A supply chain management system that supports collaboration in such cases, helps integrate suppliers as partners to add value to the overall supply chain process.

Figure: 2Supplier Relationship Management

04.Reduce Operational Costs:

Buyers or purchasing managers should be able to quickly analyze products offered by various suppliers spread across multiple geographical locations in order to secure the best pricing and reduce expenses.

The right kind of solution should eliminate wasteful spending—a critical factor in calculating the performance of any organization.

A detailed view of supplier insights can help make decisions while identifying the best supplier for various materials. Identifying solutions to balance the cost and quality of purchased materials, can help significantly reduce operational overhead without compromising on any KPIs of pharmaceutical procurement. Result-oriented companies in the life science industry should have a well-thought-out method in place to manage procurement functions, allowing them to maintain highly competitive prices without compromising the quality of a lot.

Figure: 3Better tools for modern supply chain management

Book your consultation to improving pharmaceutical supply chain procurement

Improving Organizational Efficiency is Your Key Metric:

Streamlining procurement in the supply chain, as well as identifying all possible failure points in your workflows, can significantly improve your organizational efficiency and increase the overall performance of the business. Every organization requires the ability to identify areas of their business that need improvement. Enhancing procurement in the supply chain, directly affects the utilization of materials and labor appropriately without compromising quality or cost. Optimizing resource time and inventory management together, increases efficiency. A well-planned purchasing procedure will make it easier to show incremental results on crucial analytics, such as vendor performance and spending analysis.

The Ideal System

- helps organizations streamline their pharmaceutical procurement process and get deep visibility into product inventory.

- easily and quickly identifies product and service needs, and procure products, post receipts, invoices, and payments through included procurement and sourcing management modules.

- defines purchasing policies and workflows to configure procurement processes that meet your business needs.

- manages product catalogs and procurement channels based on demand and vendor pricing and capabilities.

- defines spending limits to constrain requisition spending and the purchasing workflow.

- protects the privacy of the business and its customers.

Procurement management 2.0—Revamping technology

Any advancement in market dynamics has a direct impact on the buyer’s journey. Because of this, the need for procurement department heads to play a more strategic and tech-enabled role increases significantly. Early life science procurement departments had only two primary objectives: cost reduction and risk mitigation. Now, digital technologies have revolutionized procurement in the supply chain in companies to expand focus into different areas, like efficiency, accessibility, sustainability, and metrics for generating better purchasing decisions.

In the five years immediately following the 2008 global financial crisis (GFC), total return to shareholders (TRS) for companies with top-quartile procurement capabilities was 42 percent higher than for companies whose procurement operations were in the bottom quartile.

To stay on top, companies must move past the traditional buyer mindset, and deliver value to businesses by keeping their procurement teams collaborative with their suppliers by internally driving productivity and increasing savings, and externally maintaining better supplier relationships, and reducing unnecessary supply chain risks.

As technology continues to advance, we will continue to see new applications giving new life to the pharmaceutical supply chain in order to promote business functions.

01.Cloud-Based Platforms:

Moving procurement to the Cloud enables life science organizations to operate with more agility and with benefits, including enhanced collaboration, security, and data privacy. A growing number of traditional enterprises are already embracing the Cloud’s capabilities to accelerate their businesses. Buyers can be a lot more agile at moving materials through the supply chain if they’re managing procurement functions on the Cloud. Embracing portals and well-defined workflows, allows better engagement with suppliers, allowing the acceleration of tasks like request for quotations (RfQs).

Gartner reports that the procurement industry has an anticipated growth of up to 3.2 billion dollars by the end of 2020, fueling the Cloud procurement sector.

02.Data Analytics:

Adopting an analytically driven approach might not be revolutionary, but it’s certainly an evolution for the pharmaceutical procurement management that we know today. The significant challenges that organizations face today are primarily related to a lack of visibility.

A survey by Deloitte Global CPO showed that analytics would play a significant part in shaping procurement in the supply chain over the next two years. According to the study, the respondents use analytics in different ways:

50%for Cost optimization

45% for Management reporting

48%for process improvement

As procurement departments’ spend vs quality goal is often to exceed expectations for their businesses, turning to integrated analytics can offer innovative solutions to enable efficient resolution of ongoing buyer challenges. For best results, these teams need analytics as a core function in their decision-making process instead of treating it like a checklist submission to management. With the right reporting and analytics, life science companies should have an easy preview of the quality of raw materials per supplier. Categorizing suppliers into the proper buckets, based on supplier evaluation criteria or consuming specific lots based on customer potency/quality requirements, helps make better purchasing decisions.

03.Enhancing Collaboration:

The previous decade has seen a relatively large shift in procurement-based technology, with solutions moving from on premises to completely collaborative Cloud platforms. The initial extension of legacy ERP software systems, which included purchasing modules in the 1990s, has now evolved to easily accessible systems with enhanced collaboration and procure-to-pay solutions.

As businesspeople start exploring the pharmaceutical procurement process further, the focus is moving to niche functions, like strategic sourcing, asset acquisition, and others. These standalone technological products did nothing to solve a significant challenge: collaboration. Integrated tools, such as Microsoft Flow integrated with Microsoft Teams, are providing seamless collaboration between buyers and suppliers.

04. Mobility

With the increasing population of millennials entering the workforce, the demand for mobile devices continues to steadily rise. Deloitte predicts that nearly 42 percent of companies invest in mobile phone technologies to support their procurement strategies, meaning mobile devices should now be considered an integral part of every procurement strategy going forward. With the help of the Cloud and mobile enabled services, companies can better manage their operations and analyze real-time functions and processes, leading to more proactive decision-making.

The Role of Microsoft Dynamics 365 Supply Chain Management

Microsoft Dynamics 365 Supply Chain Management helps organizations streamline their procurement process and get deep visibility into product inventory by:

- easily and quickly identifying product and service needs and procure products, post receipts, invoices, and payments through included procurement and sourcing management modules.

- defining purchasing policies and workflows to configure procurement processes that meet your business needs.

- managing product catalogs and procurement channels based on demand and vendor pricing and capabilities.

- defining spending limits to constrain requisition spending and the purchasing workflow.

Figure 4 Optimize your supply chain with Dynamics 365

Key Takeaways

- Modern pharmaceutical and life science companies have digitized their operations and processes within the procurement department to help streamline the buying process.

- Advanced digital approaches, such as using Microsoft Dynamics 365 Supply Chain Management or automating the pharmaceutical procurement process, can help accomplish the goal of well-stabilized procure-to-pay cycles.

- A revamp in the Microsoft ecosystem’s overall procurement process enables life science companies to identify and eliminate inefficient, time-intensive aspects.