At a Glance

- ERP systems play a vital role in running the operations of an enterprise. They have a long-term impact on people and processes within a company.

- Evaluation of ERP systems is overwhelming and requires thorough vetting of various factors that are important to your company.

- This article evaluates at length, the key differentiating factors between Microsoft Dynamics 365 for Finance and Operations and SAP.

- Microsoft Dynamics 365 offers the lowest Total Cost of Ownership (TCO) among all tier 1 ERP vendors. Its payback period is 18 months lower than that of SAP.

- Microsoft Dynamics 365 offers the highest ROI of approximately $17 per one dollar spent within the first three years. This return is exponentially higher considering the ROI for competing ERP and CRM products is $7.23 and $8.71, respectively.

- Microsoft Dynamics is best suited for progressive mid-market companies aiming to make it big to support growth to an exponential degree.

You have a lot to gain or lose from an ERP system. You have established a core team to evaluate ERP systems and spent the last few months evaluating a number of Tier 1 and Tier 2 ERP Vendors. Your team sat through hours of very boring and a few exciting demonstrations of the system and how they fit your organization.

Evaluating an ERP is overwhelming. Our series of articles focused on ERP comparison will help you make informed decisions. We examine various business applications and how they compare to Microsoft Dynamics 365. Our hands-on experience in ERP systems like SAP, Oracle, Microsoft Dynamics, Infor etc. allows us to provide an objective comparison in the strengths, weaknesses and relevance of these applications.

This article provides everything you need to know while evaluating SAP and Microsoft Dynamics.

What matters?

An ERP system is at the heart of every company. It helps unify people, processes and technology across the organization so that business units function efficiently and work in unison towards a common objective.

When evaluating an ERP, here are a few key parameters that matter most –

- Business process mapping and requirement analysis

- Budget

- ERP Vendor Comparison

- Total cost of ownership

- Return on Investment (ROI)

- Out-of-the-box Features & Functions

- Duration of Implementation

- Types of Deployment

- Operational Disruption

- Competency of the partner, partner network and resources

- Evaluation of not just the application but the Ecosystem

- Technical evaluation including role of ERP in the company’s overall digital strategy

Requirements vary across organizations and so does budget – these are discussions that need deeper consultations and analysis. What stands out as a benchmark is the comparison of functionality, strengths, ease of use, pricing, and value proposition offered by vendors.

Do it once, do it right.

Microsoft has perfected it!

Microsoft has put in visible efforts towards tethering customers into a Microsoft-centric world that is themed around user-friendliness. The company’s continued investment in cloud, user experience, analytics and integration is aimed to increase productivity while reducing overall costs.

Windows from Microsoft is the most popular operating system owing to its ease of use; and per NetMarketShare, the OS is used in over 87% of desktop/laptop globally. Continuing its recipe for success, Microsoft has ensured that the Dynamics platform resonates similar minimalistic yet powerful productivity & design elements of Windows. Multiple acquisitions including Navision, Axapta and Great Plains have helped Microsoft build its flagship ERP product today – Microsoft Dynamics 365 for Finance & Operations.

Microsoft Dynamics 365 for Finance & Operations has been built consistent with the intent of creating a simple, powerful and a common ecosystem. An ecosystem that is easy to use, secure and scalable.

Microsoft Dynamics 365 arguably enjoys a dominant position across small and medium enterprises. The scalability of the application has allowed successful deployments at large retail and manufacturing companies with thousands of users. Microsoft Dynamics has established itself as a viable alternative by voiding the complexities of larger applications such as SAP and Oracle.

Below are just a few well-known large enterprises that use Microsoft Dynamics 365:

Microsoft Dynamics 365 vs SAP – The Comparison

Factors such as implementation time, time to achieve stable state, disruption to business functions are amongst the top qualitative parameters.

- Per Panorama Consulting, Microsoft Dynamics 365 users reported an average 12 months implementation time compared to its peer SAP with close to 15 months’ time.

- Average timeline of 12 months is relevant to medium and high complexity implementations.

- For smaller companies and low complexity implementations, the time to implement is less than 12 months. Get more information from XcelPros on rapid / accelerated implementations for Microsoft Dynamics.

- Compared to SAP, Microsoft Dynamics 365 users took maximum of two months to achieve stable state as against six months in case of the former.

- The above finding was also echoed by Forrester Research which reported that SAP users experience more material operational disruption during their implementations than the other Tier 1 providers and that Microsoft Dynamics 365 had the fewest (2017).

Microsoft made it simple, making it an ideal software for mid-market companies.

- As evident from the above comparison, Microsoft Dynamics 365 scores over SAP in most categories including critical parameters such as time for installation, ease of customization, user experience, TCO, and customer support.

- A business user needs simplicity. Unlike SAP, which has approx. 70,000 screens for a user to navigate and discover what is useful for his business, Microsoft provides ease of use resonating the very familiar daily used products such as Outlook, Word and Excel.

- Dynamics 365 allows users to customize the aesthetics of the system for a personalized experience. This includes customization of themes, color, user dashboard both on desktop and hand-held devices including mobile.

- With embedded business intelligence, the platform assimilates and analyzes customer data to understand patterns and suggest appropriate actions so that sales and marketing organizations are better equipped. Features such as relationship assistant, cortana intelligence, auto capture, and email engagement help gather better sales intelligence and actions thereafter.

- With Microsoft’s vast ecosystem, Dynamics 365 users can access every module within the system, without the need for investing in other applications. Upgrades and security patches are seamlessly delivered automatically through cloud without causing any disruption to the business functions.

A user story highlighting the power of Microsoft Dynamics 365

Background: A multinational Jeweler needed to modernize its IT services to make use of data collected over time and move from predictive analytics to peerless point-of-sale customer experience.

Problem statement: The global Jewelry house wanted to empower its sales and marketing team with an unified and all-inclusive customer database to create a personalized experience for its customers across all channels (in-store, web, and mobile). They needed to overhaul their IT system to reflect modern age aspects of the business involving back-end IT to POS interactions and facilities management.

Solution: The Jeweler entrusted this responsibility on Microsoft Dynamics for Retail, Finance and Operations, and Customer Service. Integrating information across stores and online channels, staffers were equipped with behavior and purchase patterns of their customers. Using a mobile device, sales personnel were able to access the business relationship, personal information such as birthday, anniversaries, special occasions, to develop better personalized relationship. Marketing team was able to enhance the relation with curated messaging, new product launch and discount offers.

Result: With data consolidated and centralized within Microsoft’s ecosystem, pulling up customer data that otherwise took four minutes were available in few seconds. Using Power BI, the company was able to create actionable insights visualized over an interactive dashboard. With the assurance and reliability of Microsoft’s ecosystem, the Jeweler was able to streamline business processes that helped in further expansion of business.

Power of One-Microsoft Ecosystem

Microsoft ecosystem includes a comprehensive suite of applications ranging from analytics, visualization, artificial intelligence, IoT, PowerApps, CRM, Office 365, and a host of other third-party applications. The seamless integration and the communication of these applications is the key differentiator between Microsoft and any other applications in the market. A few benefits of the ecosystem –

- Improved connectivity without the need for customizations

- Improved productivity to enhance efficiencies

- Improved visibility of information across business functions

- Ability to download and implement additional functionality / apps from appsource.microsoft.com. This gives you the power to scale with industry and function specific apps on Microsoft Appsource.

Ex. Integrated Chemical Management (iCM) – This provides extensive functionality in Label Management and SDS Management for Chemical, Pharmaceutical, Life Sciences and Food Industries. Anyone that works with chemicals – industrial, pharma or food grade will need this app. Every company in these industries needs SDSs and be able to print labels. Without this app, companies need to spend tens of thousands of dollars to customize Microsoft Dynamics 365 workflows, reports and many more elements. - Capabilities to support CRM, ERP, and human capital management modules

- Higher accuracy to determine project costs and increased operational efficiency

- Seamless integration with SharePoint / best document management system

- Advanced analytics and scope of cross-selling/up-selling using Field services

- Collaboration and visualization

- Application development (with PowerApps)

- Higher efficiency when onboarding vendors/customers due to familiarity with other Microsoft products

Higher Return on Investment (ROI) and Lower cost of ownership (TCO)

Cost is one of the key parameters that differentiates Microsoft Dynamics 365 from its competitors. Dynamics 365 is designed to be flexible to adapt to the changing needs of customers. Independent surveys conducted by research and consulting houses unanimously rate Microsoft Dynamics 365 to have the highest return on investment (ROI) and low overall cost of ownership platform.

- Microsoft Dynamics is offered on-premise and in the cloud

- Licensing has been designed to include all roles and responsibilities within an enterprise.

- At a high-level, On-premise and Cloud have 3 tiers of user licenses and a device license.

- Cloud is priced at per user per month

- Full Access / Enterprise – $190

- Functional User – $50

- Task User – $8

- On-premise is priced at a one-time license fee + 16% Annual Maintenance Fee

- Per a study by Nucleus Research, Microsoft Dynamics 365 offered the highest return on investment, recovering approximately $17 per dollar spent. This number is exponentially higher considering the combined ROI for ERP and CRM at $7.23 and $8.71 respectively.

Microsoft Dynamics 365 can scale up/down with your changing business needs

Scalability is a key element of the ERP you choose. Only Microsoft allows use to scale up/down as per your business needs. In the case of on-premise, you have the ability to lock your maintenance to the price paid at the time of signing the contract. Customers like this flexibility to add / alter licenses as their resource & business needs change.

- Benchmarked with efficient performance scaling up thousands of users, Microsoft is completely capable of handling your business requirements. It offers extensive functionalities across financials, supply chain management, and customer relationship management.

- Ex. You can start with the ERP today and add Microsoft Dynamics CRM later. The scalability aids in adding functionality later as required.

- Dynamics 365 offers enterprise-wide reporting, powerful business insights, tools that support decision making – all these at a relatively lower cost while scoring high on flexibility and ease of use.

Take Our Assessment to Get Started With Digital Transformation

At a Glance

- On-time delivery (OTD) is a key metric to measure delivery performance and supply chain efficiency in your organization.

- This article talks of a real-life transformation of OTD in a chemical company from 76% to 90%+.

- Your ‘A’ customers contribute to more than 70% of your company’s revenue and meeting their sales order demand is critical for customer retention.

- Improvement of OTD requires optimization of processes across multiple departments in the organization.

- Prime reasons behind late product delivery – lack of real-time data-driven insights, planning, monitoring, and operational efficiency.

- Technology and integrated tools play a pivotal role in the monitoring / increase of OTD.

- The OTD percentage is a holistic measure of operational performance.

On-time Delivery – Industry Disruptors

Amazon has been a major disruptor in the industry and changed consumer perception by delivering shipments within the promised 2 days. The operational efficiencies required to run Amazon’s distribution centers is no joke. Other retail giants have now been forced to follow suit and meet the high standards set by Amazon. The expectation of on-time delivery is now more than ever before in traditional industries such as chemical, pharmaceutical and distribution.

Here are a few KPIs that are critical to measure delivery performance in Logistics and Supply Chain operations –

- On-time Delivery (OTD) also referred to as On-time Performance (OTP), Shipped-on-Time (SOT) or Delivery on Time (DOT)

- DIF – Delivery in Full

- DIFOT – Delivery In Full on Time

- Inventory Turns (days)

- Costs as a percentage of sales

This article contains real-life experiences of a general manager and executive of a chemical company. We will discuss the key contributors to on-time delivery and how by starting with a low percentage of OTD you can achieve significant gains over time.

The realization

- You are responsible for managing operations and see some glaring issues. However, you are not able to pinpoint the precise problem or where to even start. You request Key Performance Indicator data (“KPI”) from different departments.

- As you begin your review, you notice a lack of focus – i.e., there are several KPIs, all being portrayed as having an equal value. One logistics KPI stands out: The On-time Delivery (“OTD”) percentage within the company is only 76%. Upon reflection, you realize efficiency can be enhanced by managing operations with this single measure.

- In this blog, we will elaborate why OTD is so important. This single KPI can drive tangible value for your customer and totally change how customers perceive you. Our next blog in the same series expands on the problem/opportunity you inherited, the steps you can take to produce rapid positive results and finally the result achieved.

What is OTD?

OTD is a metric used to assess the ability of a business in fulfilling the shipment order within the period of promised delivery date.

On-time Delivery (OTD) – The Logistics KPI Defined

The On-time delivery performance refers to the ratio of customer order lines shipped on or before the requested delivery date / customer promised date versus the total number of order lines. This is usually expressed as a percentage and can be calculated for several measurement periods.

Figure 1:The procedure of order fulfillment to ensure on-time delivery (OTD)

What is required to Deliver On-time?

- 1.You have forecasted estimated demand, ran MRP and ordered materials. You create a purchase order for the required materials.

- 2.The materials are received, recorded and put into your raw material stores area.

- 3.An order has been received, you check available inventory, determine that you can produce the order and promise your customer delivery on a specific date.

- 4.You create a work order and issue it to production.

- 5.The materials are correctly picked, moved to the production area and produced.

- 6.Inventory is yielded and quality confirms that the produced inventory meets product specifications.

- 7.Inventory is put-away to the finished good-storage location.

- 8.Per customer promised date, inventory is picked and delivered to the shipping dock where proper shipping documentation is prepared. In chemical or pharmaceutical companies, shipping documentation typically includes other documentation such as Certificate of Analysis (COA), SDS etc.

- 9.The delivery is scheduled, the truck arrives to take the finished goods away and the delivery arrives on-time and undamaged.

- 10.You just executed the perfect On-time Delivery and, most importantly, your customer is happy that you met their expectations.

Why is OTD Important?

- On time delivery drives better collaboration with your customers, ensures reliability of delivery and most importantly customer loyalty.

- Customers expect you to meet the promised delivery date. It is important to set the right expectations with your customers and meet them. If you can’t meet your customer’s expectation and deliver on time then they will find a supplier who can.

- Consistent problems with on-time delivery will not only disrupt your business or result in loss of reputation but will also affect many other areas of a company’s supply chain and can irreparably damage customer relationship and long-term success.

How to deliver on time?

- Understand and track the late delivery reasons, analyse the various factors that contribute to late delivery and identify the root cause.

- After identifying the root cause and the issues in late delivery, prioritize the issues and focus on the actionable steps to success.

- Develop a plan and implement it.

- Monitor results and revise the plan accordingly.

Reasons for late deliveries

With that in mind, think about all the things that can go wrong. The occurrence of any one of the following errors will result in late delivery. Most companies use a Customer Relationship Management (“CRM”) system to track and resolve customer complaints. If you are a pharmaceutical customer, the emphasis on quality is significantly higher therefore imperative to manage these inefficiencies a lot closer.

- Bad forecasts

- Sales over-promising

- Incorrect lead-times and safety stock levels

- Purchase order errors

- Supplier delays

- Inventory inaccuracy

- Receiving data entry and put-away errors

- Production picking errors

- Bad standard operating procedures (“SOPs”)

- Production operator errors

- Maintenance and equipment related issues

- Quality delays

- Product rejections

- Material handling put-away errors

- Shipping department picking and packing errors

- Shipping documentation inaccuracy

- Delivery scheduling and late pickup

- Damage in transit and late delivery, etc.

- Customer changing orders constantly without a proper procedure in place

- Customer’s inability to handle products received in full – This could be due to lack of storage space, personnel or any other intrinsic reasons etc.

The OTD percentage is a holistic measure of operational performance. It measures an organization’s ability to manage its supply chain in a predictable manner. If you live up to the promises you make, you create value for your customer.

Success Story 1

One of our clients, a US-based chemical firm lacked the inventory management software and barcode to line out its full inventory of warehouse and manufacturing facility. To provide an effective solution, Xcelpros designed a new bar code scanning technology for the company along with durable, custom labels to improve data capturing and enhance operational efficiency with an ‘integrated material requirement planning system’.

It took us three weeks to give a closure to the entire label installation process without causing any disruption to the live operational environment. We successfully lined-out the warehouse, and the results were great.

- Eliminating manual data transcription reduced the scope of error

- Automating the procedure helped to minimize the time in materials management

- Limiting the frequency of materials-related changes in the production schedule

The chemical company now functions at close to 95% on-time delivery, a 30% increase in operational efficiency—with a 20% reduction in inventory.

Success Story 2

We had to come up with a technological solution for arranging on-time delivery at multiple distribution centers for a client. Managing this complex grid of network to successfully manufacture and deliver the products on time demanded continuous monitoring of production facilities, logistics hubs and consolidation points.

We came up with a supply chain visibility model using advanced analytics to track the order status in the supply chain. We developed a dashboard and reorganized the orders with a clustering approach as per source, delivery destination, stock keeping units (SKUs) etc so that the status of the each individual product is tracked. Following this methodology gave our client a complete visibility on their product status and delivery performance. The real-time data generated better insight across the supply chain, and corrective measures were taken on an immediate basis to manage the impact of late delivery.

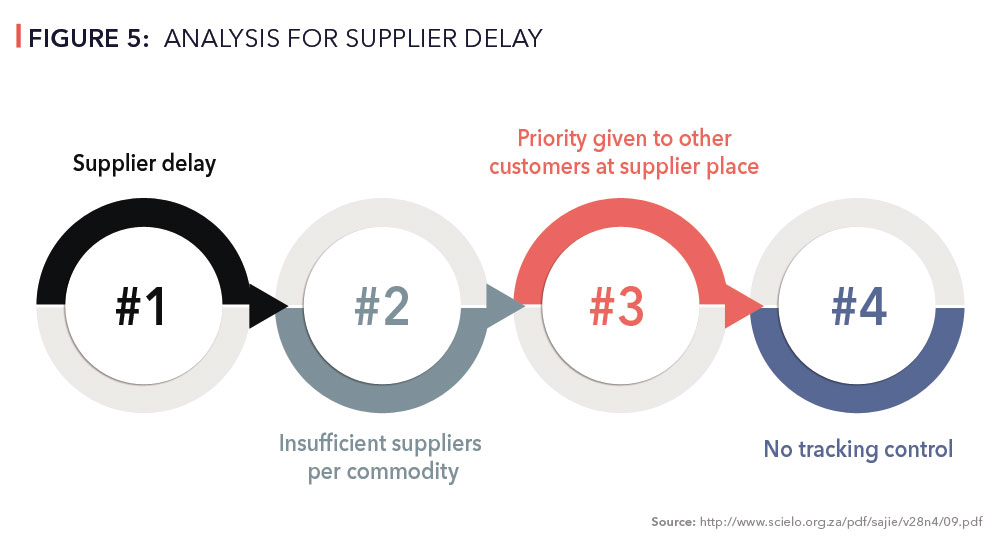

Figure 4 depicts the analysis of insufficient lead time given to the supplier. The root cause of this insufficient lead time is the delay and long-stretched process – from the material requirement planning (MRP) to purchase request (PR), to purchase order (PO).

Figure 5 analyzes the key reasons behind supplier delay, which need to be addressed. It pinpoints “no tracking control” to be the prime reason that causes supplier delay.

One of the major concerns here is how to keep a track of MRP-PO-PR conversion if you don’t have any component for tracking control. This lack of monitoring brings operational inefficiency due to which there has been a gap between the agreed time and the actual time of delivering the components. They are found to be the major bottlenecks in achieving OTR and thus OTD.

The solution is to develop and design a lean live tracking (LLT) system for the ease of monitoring with very low manual intervention. It aids to bridge the gap between PO releases to suppliers and production completion.

Focus on what matters!

Why you should care about your business processes?So, having determined that the On-time Delivery (“OTD”) KPI is the best holistic operational performance measure, I needed to understand how it was possible that we were only satisfying customers only 76% of the time. I conducted a detailed review of every major supply chain and operational process within the company. I found that were quite a few systems and business processes that were inefficient and needed improvement.

Areas that Needed Improvement

- Over promise by sales team on delivery time – Our problems started with sales promising customers a delivery date without any conversation with the Customer Service department. Sales and Operations teams struggled to meet the demand dates leading to a ripple effect downstream. Lack of clear policies and standard lead-times for both make-to-stock (MTS) and make-to-order (MTO) products was the first domino to fall.

- Training – Poor training served to maintain our ISO certification, but was more formed than substance, and it caused issues in virtually every functional area of our business. An emphasis on training is critical for Organization’s success and its most effective when imparted on the job.

- Standard Operating Procedures (“SOPs”) – Outdated and incorrect SOPs resulted in inconsistent management of inventory and transactional errors. In fact, incorrect SOPs resulted in higher levels of scrap and out-of-spec products that were being rejected by the quality department. The process to main

- Communication – The lack of communication with shipping department led to shipping document inaccuracy, late pickup and packing errors. And negligence of shipping department further led to damage in transit.

- Transparency in process – Moreover, the lack of visibility to downtime and other operational delays further negatively impacted our ability to deliver on-time. These shortcomings drove a lack of consistency, repeatability and predictability.

Little Faith in Company’s Material Requirements Planning System – Lack of a sophisticated ERP

- A failure to maintain proper and timely planning parameters (lead times and safety stock levels) coupled with inaccurate sales forecasts resulted in production planning and procurement managers abandoning the company’s Material Requirements Planning (“MRP”) system and instead managing operations using “Tribal Knowledge” and gut instincts.

- Managing chemical operations using spreadsheets and gut instincts lead to other problems. The procurement manager approved purchase requests to buy material significantly in excess of what is required to meet the demand. This lead to a huge amount of capital being stuck due to this excess inventory.

- This same mentality existed in the production department, where rather than relying on SOPs, products were being manufactured from memory which led to production errors, inventory inaccuracy, poor quality and product rejections.

- This, of course, resulted in operators marching to the beat of their own drum and many variations in the products being delivered to quality for review.

Lack of Communication Between Associates

- When I considered the lack of well-defined business processes and faith in our systems, I began to believe that 76% On-time Delivery wasn’t bad – How did we deliver anything on-time?

- It seemed like every order had a problem, causing a late delivery and an investigation always resulted in some culprit who was responsible for acting on their own and making assumptions, rather than following a prescribed, repeatable and consistent process.

- This promoted an environment that lacked trust, promoted finger-pointing and made it hard to communicate and act like a team.

Considering Root Cause Analysis (RCA) as a critical factor

- Whenever a failure or deviation occurs, there should be a proper infrastructure in place so that RCA can be done efficiently in an optimal duration.

- There should be a way to backtrack how the incident happened and capture the information i.e. in case of hardware failure there should be logs, archives, backups. There should be a way to capture and backtrack all business metrics responsible for the incident. Like a plane crash investigation, we should be able to backtrack and find what happened before seconds to disaster.

These are just a few opportunities that need improvement. Most of these can be addressed by virtue of a system / technology that connects the business processes within various departments / functions in the company.

Start Your Digital Transformation Journey with Assessment

Change is the only constant and resistance to change is natural. Change management is imperative in establishing a balance amid these aspects.

An organization undergoes a major change while embarking on an ERP Implementation. The new system, processes and learning results in a resistance towards change. Organizations need to undergo change to be in sync with changing markets and business dynamics. Most organizations don’t realize the significance of change management for their chosen ERP solution till after the implementation. At this stage the solution, which now includes people, processes, and technology, may need continuous updates as the organization transitions, to perform at its best.

The infographic explains why change management is integral to an ERP implementation, the challenges involved and how shaping a change management strategy ensures a smooth transition within your organization.

Take Our Assessment to Get Started With Digital Transformation

Since its inception, IoT has been gaining popularity rapidly in the tech market. Though it has been widely accepted in the consumer level, its application is found to be less in the corporate world. This is because the true potential of Internet of Things is not yet unleashed to many corporate executives.

This infographic gives you a detailed overview of the benefits of IoT application in the healthcare and manufacturing industry. Learn how IoT sensors help businesses monitor and automate the processes and enhance operational efficiency.

To get more information on how IoT will impact your business and customers, talk to an XcelPros expert today. XcelPros will transform your business with IoT Technology solutions.

Start Your Digital Transformation Journey with Assessment

In recent times, Blockchain has been a popular topic of interest for companies big and small. This infographic discusses one of its most popular applications, i.e., Blockchain in payment processing. It starts by explaining how the transaction is processed through a P2P, tamper-resistant decentralized network and then pinpoints the services where the application of blockchain is mostly observed.

Learn the key facts of Blockchain and its role in financial services. Here is an infographics you will love!

Start Your Digital Transformation Journey with Assessment