Chemical companies always look for ways to optimize their operations and maximize profits. Today, one of the most effective ways to achieve these goals is by implementing a modern chemical ERP (Enterprise Resource Planning) system. Microsoft’s Dynamics 365 finance and operations (D365) software is part of an advanced, cloud-based platform that fits most chemical companies perfectly. This blog explores how most chemical companies benefit from Microsoft’s D365 for Finance.

According to a survey conducted by Forrester Consulting, chemical companies that have implemented Microsoft Dynamics 365 for Finance and Operations have experienced a 20% improvement in operational efficiency, a 15% increase in customer satisfaction, and a 10% reduction in supply chain costs. This highlights the significant impact that Dynamics 365 is having on chemical companies and their ability to streamline operations, improve customer service, and reduce costs.

What is Microsoft Dynamics 365

Microsoft’s D365 is an industry-favorite, integrated ERP solution providing a wide range of business functionality for finance, operations, sales, customer service, manufacturing, supply chain management, project service automation, and more.

The Dynamics platform is designed for use in any business environment, whether a large enterprise, SMB, or hybrid-remote blend. The current version of D365 focuses on helping organizations streamline processes, increase productivity, and gain greater visibility into their operations.

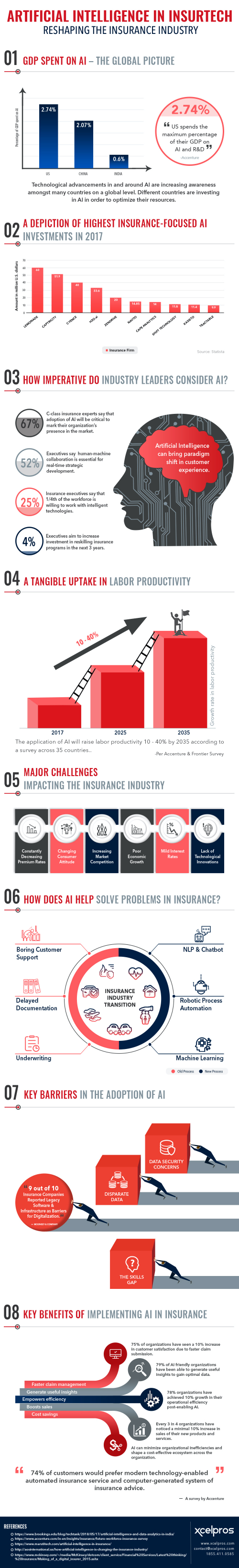

With advanced AI/ ML (Artificial Intelligence / Machine Learning)-powered analytics, deep integration, and cloud computing capabilities, D365 gives organizations real-time insights into their operations. The system also allows users to track and monitor performance, manage financials and accounts payable/receivable, and improve operational efficiency. Leveraging the power of the cloud and the efficiency of modern artificial intelligence (AI), D365 can help organizations reduce costs and create unmatched value across their enterprise.

How is D365 being used by chemical companies?

Today, Microsoft’s D365 is used by chemical companies to streamline every part of their operations. The platform has been refined over time to integrate seamlessly with existing business systems, making it easier for companies to take advantage of a growing list of powerful features quickly. D365 allows chemical companies to reduce costs and improve efficiency by automating key financial processes.

One of the biggest advantages for chemical companies after implementing Dynamics 365 is far better control over their inventory. With integrated inventory management functionality, these businesses can track their stock levels in real-time, allowing them to adjust their ordering and production schedules accordingly. This helps ensure that there are always enough materials to meet customer demands. In addition, integration with other systems gives businesses a more accurate view of their supply chain, enabling them to identify areas where they could save money or streamline processes.

Another major benefit of using Dynamics is better visibility into financial performance. With a clear, up-to-date picture of current financial health, businesses can make more informed decisions about optimizing their operations. This includes identifying cost savings opportunities, improving their cash flow, and gaining insights into areas marked for improvement.

Year after year, Microsoft D365 continues to prove itself as an invaluable tool for chemical companies. By helping businesses reduce costs, gain greater visibility into their operations, and more effectively manage their inventory, Dynamics 365 finance and operations software is helping these companies take their business to the next level.

What about the benefits?

Across the industry, we see an increasing chemical companies taking advantage of the powerful features included in Microsoft Dynamics 365 to optimize their business processes and operations.

This includes the ability to streamline operations with automated workflows, increase visibility and control with real-time data and analytics, and enhance customer service.

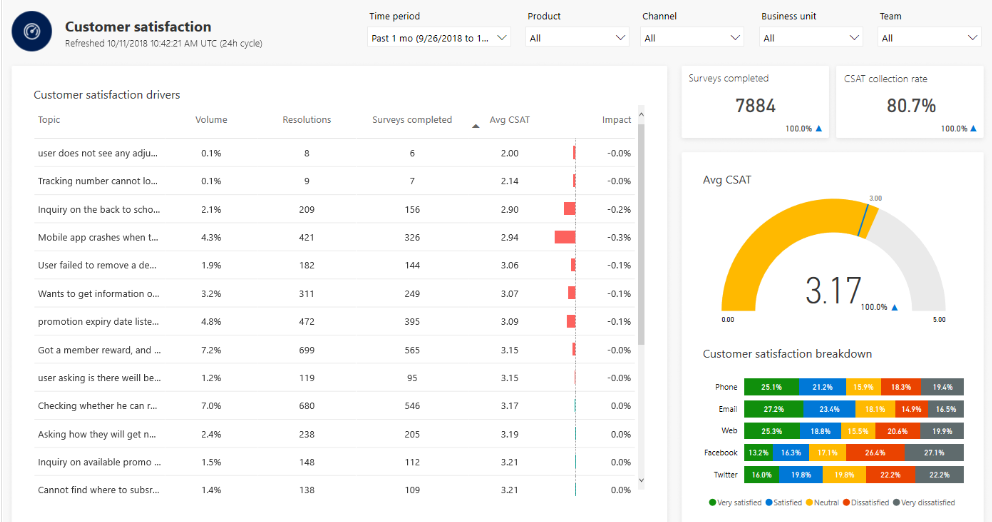

Figure 1:Benefits of Dynamics 365 Finance for Chemical Companies

The ability to integrate D365 with other industry-specific solutions gives chemical companies more insight into their production and inventory management, along with their financials.

The ability to make more informed decisions helps these companies reduce their costs by reducing the number of materials that go unused, and through better planning of their production cycle. These companies end up improving their customer service with faster order processing, real-time tracking of orders, and automated notifications when an order is ready for delivery.

Overall, the use of D365 provides chemical companies with numerous benefits, from increased visibility and control over their operations to reduced costs and improved customer service. As the industry evolves, companies will continue to find new ways to capitalize on the features of D365 to stay competitive.

Schedule a call to Learn more about the Benefits of Dynamics 365 Finance for Chemical Companies

What does the future hold?

Year after year, the future of D365 continues to look extremely promising. As the platform continues to evolve, chemical companies can leverage more advanced capabilities to streamline their operations further. This includes improved automation, data analytics, machine learning, and artificial intelligence designed to help optimize processes and uncover deeper insights. Cloud-based functionality will continue to be a major component of this platform, enabling companies to access their data from any device, anywhere in the world.

In the coming years, we will see more organizations leveraging Dynamics 365 to achieve their business goals. These companies should consider investing in this technology sooner than later to remain competitive. With various options available, businesses of all sizes should be able to find a solution that meets their specific needs. Not sure where to start? This is where most businesses look to their trusted Microsoft Partner to help understand what products suit the needs of their business, both now and in the future.

User stories

User stories are a fantastic way to show how other companies achieved success with Microsoft’s finance and operations software. User stories highlight the versatility of D365 and its ability to support a wide range of business functions, from sales and marketing to finance and operations.

Whether you are considering implementing D365 for the first time or looking to expand your current platform use, user stories provide insights into how other businesses have successfully navigated the implementation process and used D365 to drive their desired outcome.

Chemical Manufacturing

A well-known chemical manufacturing company produces and supplies various products to customers worldwide. As part of their mission to be more competitive and stay ahead of the industry curve, they decided to invest in Microsoft Dynamics 365.

The cloud-based solution allowed the company to quickly get up and running without needing a lengthy on-premises installation. The system immediately provided the company with real-time visibility into its financial performance and a comprehensive overview of its operations. As a bonus, the company could access data securely and easily connect to its existing systems.

After implementing D365, the company quickly realized increased efficiency, transparency, and accuracy across its financial and operational processes. The platform has enabled the company to streamline its supply chain, reduce inventory costs, and improve customer service by providing an accurate view of its inventory levels. They also found themselves better positioned to manage their production and procurement processes, allowing them to respond quickly to customer demands.

Conclusion

Microsoft Dynamics 365 for Finance is becoming invaluable for chemical companies looking to streamline their processes, increase efficiencies, and save time and money.

With robust capabilities and flexibility, D365 can provide the support needed to make more informed decisions and the ability to automate many complex manual tasks. The result is a more organized and efficient organization better equipped to serve customers and grow.

Deciding to go with Microsoft D365 allows chemical companies to benefit from streamlined processes, improved accuracy, increased visibility into their financial operations, and better customer service. In addition, they’ll have access to powerful insights that help them make better decisions leading to growth and success.

With Microsoft Dynamics 365, chemical companies can be assured that they are making the most of their resources and maximizing their growth potential. Not sure where to get started? Work with your partner to ensure you’re both on the same page. Need a push in the right direction? Our team is waiting to answer your questions. Get ahold of us today!