Inventory can be your best friend or worst enemy, depending on how well it’s managed. If your business is experiencing issues managing its inventory, it’s time to take charge of your inventory management process. And prevent it from becoming an ongoing headache.

In this post, we look at the importance and benefits of inventory visibility and how to make inventory more accessible.

The importance of inventory visibility

Inventory visibility – One of the most frustrating aspects of running any business is tracking inventory levels so you know when it’s time to restock. Or, when products need to be sold off before they go bad.

This applies to finished goods and the raw materials used to make them, work-in-progress items (WIP). And anything used in maintenance, and repairs or operations (MRO).

Good inventory visibility means your inventory can be managed with as little hassle. When you can monitor what products are available and what quantity is in stock, you’re better equipped to make decisions that will help you manage your finances effectively.

It also goes a long way to reducing costs and offering a better customer experience. Proper inventory visibility makes it easy to track products and raw materials anywhere in the supply chain. Better visibility of your inventory leads to better visibility of your orders. From production to shipping and delivery.

Achieving Inventory Visibility

For most companies, inventory management is best left to dedicated solutions, like Microsoft Dynamics 365. Inventory systems like D365 help manage critical items like location, availability, status, cost, and stock levels.

Common practices to increase inventory visibility can include things like:

- Increasing the accuracy of data captured for all products in your system.

- Taking advantage of mobile devices and handheld scanners in fulfilment areas to track products in the supply chain.

- Conduct regular audits and cycle counts against current inventory levels.

- Investing in a modern inventory management solution that offers visibility of all raw materials and finished goods for multiple locations or channels.

Benefits of good inventory visibility

With enhanced inventory visibility, businesses can pinpoint any issues’ root cause faster than ever. Full visibility of your inventory means you’re in a perfect position to solve any problems. Without proper inventory visibility, it can be exceedingly difficult to generate accurate reports about your stock levels and costs or be able to manage orders. Or track items across different sites.

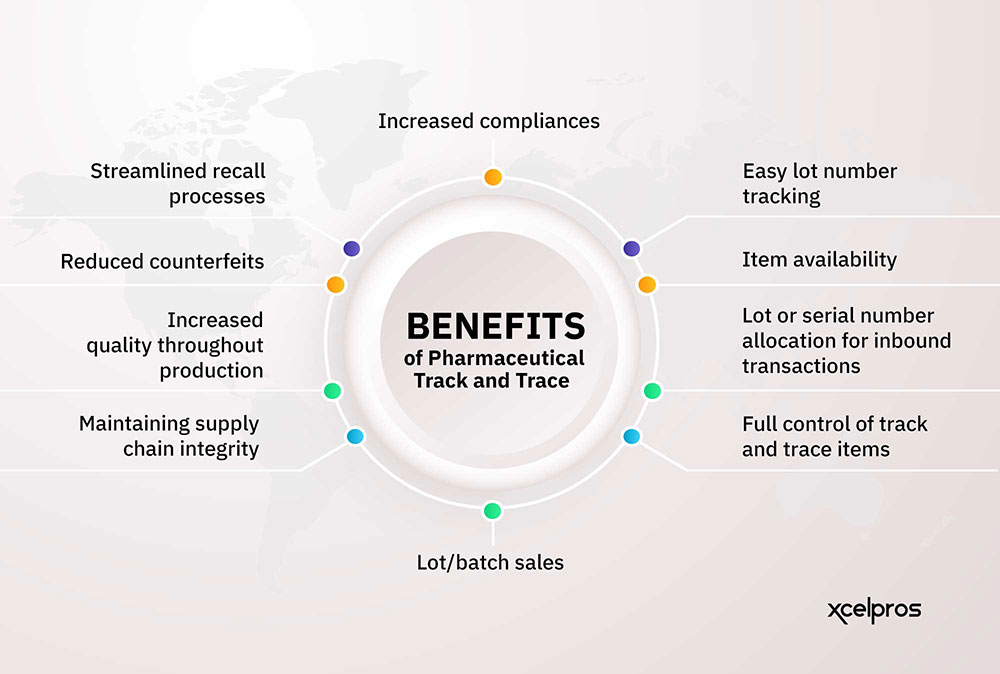

Some additional benefits of good inventory visibility include:

Figure 1:Benefits of Good Inventory Visibility

- More efficient operations – Inventory visibility means you’ll reduce the amount of time you spend managing delays, complaints, or missing items.

- More control of inventory and stock levels – Inventory visibility lets you reduce overstock as well as ensure you don’t run out of any must-have products.

- Better security – Especially for highly regulated industries, inventory visibility is critical for tracking the movement of finished goods, raw materials, and specific batches.

- Better response to customer demands – Improved inventory visibility means you’re always better equipped to meet changes in demand – This is one of the best ways to create a better customer experience.

- Better resource allocation – Inventory visibility help you understand how much stock needs to go to different locations like warehouses, retail outlets, and more.

- Increased forecasting accuracy – The data captured from good inventory visibility gives a better view of products you need to keep on hand. And improving distribution and purchasing at the same time.

- Better responsiveness – Real-time inventory data lets you quickly respond to any changes in demand based on trends or other disruptions.

- Better ROI – Better visibility means you can reduce your stock levels across the board, without disrupting the needs of your customers.

Inventory visibility challenges

Inventory visibility can indeed be challenging, especially without a dedicated system. Today, omnichannel marketplaces offering a growing list of new fulfillment options like Buy online pickup-in-store (BOPIS), drop shipments. And more means there is an increasing list of issues that can arise.

Some common challenges with achieving inventory visibility include:

- Manual processes – Manual processes are notoriously inefficient, especially when we have access to barcoding solutions and automation.

- Poor visibility – Not being able to track your finished goods or raw materials means you can create several unplanned delays, resulting in a less-than-stellar customer experience.

- Unknown demand – Lack of visibility makes it easy not to understand the demand for your products; this quickly leads to overstock or understock conditions.

- Re-stock issues, loss of business – Lack of visibility can lead to several missed restocking opportunities and more business for your competition.

These are all issues that can be harmful to a business. And leading to loss of revenue, damage to your reputation, a poor customer experience, or worse.

Improving inventory visibility with Microsoft Dynamics 365

Many retailers struggle with visibility into their inventory – not only can it be time-consuming and costly. But, it can also lead to out-of-stock items or delayed shipments.

Microsoft Dynamics 365 offers many features that can help you improve inventory visibility, including creating multiple levels of item locations and reconciling inventory automatically and manually.

Some of the ways D365 helps improve the visibility of your inventory can include the following:

Figure 2:Improve Inventory Visibility with Microsoft Dynamics 365

- Support for mobile and handheld devices – Microsoft Dynamics fully supports shop-floor devices designed to minimize redundant manual processes.

- Process and route optimization – Microsoft Dynamics let you customize and streamline your processes, resulting in highly optimized routing throughout your supply chain.

- Process automation – Microsoft Dynamics gives you more control of the automation of your processes, which not only increases compliance. But also significantly reduces time spent on repetitive tasks.

- Actionable insights – Microsoft Dynamics allows businesses to extract more data from everything they do. Forecasting, scheduling, routing, and more all become much more efficient.

- Electronic signatures and approvals – Electronic signatures in D365 are quicker, more compliant, and much easier to track.

Final thoughts

While challenging, inventory visibility has become more important than ever before, continuing to prove itself as one of the best ways to streamline your company’s operations.

However Improving inventory management doesn’t have to be difficult, especially in today’s rapidly changing marketplace. Once you understand your specific requirements, the best way to start on the right path is to work with a partner who understands your industry’s ins and outs. And can help implement a solution that’s perfect for you.

Schedule a call today to discover how we can help optimize your inventory visibility.

References: Inventory Visibility Add-in overview