Words can be like X-rays, if you use them properly—they’ll go through anything. You read and you’re pierced.

At a Glance

- The outbreak of an epidemic has brought the global supply chain to a halt, pushing major global economies towards a crash of financial markets and recession. The focus at this time should be safety, recovery and cure instead of worrying about lack of essentials due to stunted supply chains.

- There is a need to create an ecosystem of businesses that are collaborating through a well coordinated and integrated supply chain to allow more stability even in a crisis.

- Many factors that are well thought out can contribute to a better global technological footprint where businesses across the globe can facilitate more growth and well-being of economies.

Introduction

During difficult times the world requires better ways to function without taking the entire economy down. One such event is the Coronavirus outbreak that caused a ‘slow down to shut down’ of all businesses due to the pandemic. Since the 90s when the computer technology revolution happened, we have seen various situations of slump and recession that gave rise to newer ways to function and advent of disruptive technologies changing the face of the world. Increased globalization and interdependence on different economies made the world a better place with enhanced living conditions and more opportunities to easily navigate through the world.

Figure: 1 Automated supply chain and distribution using bots, drones connected via cloud technology controlled remotely by people

Many disruptive technologies came to life during the last 3 decades that are now in every man’s pocket. We all know what they are. Smartphones, Internet, Direct to consumer tools, Search portals, AI, ML, BOTS, IOT,…..and the list goes on. This coronavirus pandemic however is showing us that we are not fully integrated yet. Why has the world slowed down when we have so many technological advancements and tools out there that were created to never face this situation? As such countries need to focus on safety, recovery and cure instead of worrying about not being able to supply essentials due to social distancing. This is not a case of a tsunami that has destroyed road infrastructure, it is merely a need for people to work remotely and avoid exposure, and an inability to control movement of the supply chain from the comfort of your home.

By 2023, over 30% of operational warehouse workers will be supplemented by collaborative robots.

With this statistic, you would never really expect to see businesses or trades freeze, as operations would run smoothly with a proper collaboration.

A major blind spot has surfaced. A lack of being able to control the global supply chain seamlessly from a remote location with the press of a button. This lack is causing millions to lose their life savings in 401K plus other investments, driving to a bad economic situation. By the time the world has recovered from the pandemic, you are now dealing with an unplanned financial mess.

Added to that is an unfortunate imbalance in prices of all commodities as they are unable to handle the reaction of the slowdown impacting life of an average consumer and creating a downward spiral in the market sentiment as well as lowering the morale of people. Natural course of life is always towards moving upwards until a huge obstacle surfaces due to such incidents. The blind spot here is:

- not being able to foresee a situation that could force us to stay isolated and is not enabling us to move things around without any hindrance.

- of a holistic system that does not have enough integration between all the isolated systems that are in place.

We have seen glimpses of hightech warehouses with inventory arranged on pallets, controlled by bots that receive an order and move them to packaging areas. But taking the vision further, imagine the following scenario:

Figure: 2 Fully integrated warehouse operations monitored and managed via off site operators

A hightech warehouse with functions such as inventory management, packaging and shipping, fully handled by bots controlled through a device by a warehouse operator, shipment load planning done through a bot, and shipment automatically scheduled once the transportation planner firms the plan. A truck that is in-transit can be monitored by the planner. All of this is achievable through integrated technology that can manage the supply chain at every point of operation.

By 2022, application integrations delivered with robotic process automation (RPA) will grow by 40% year over year.

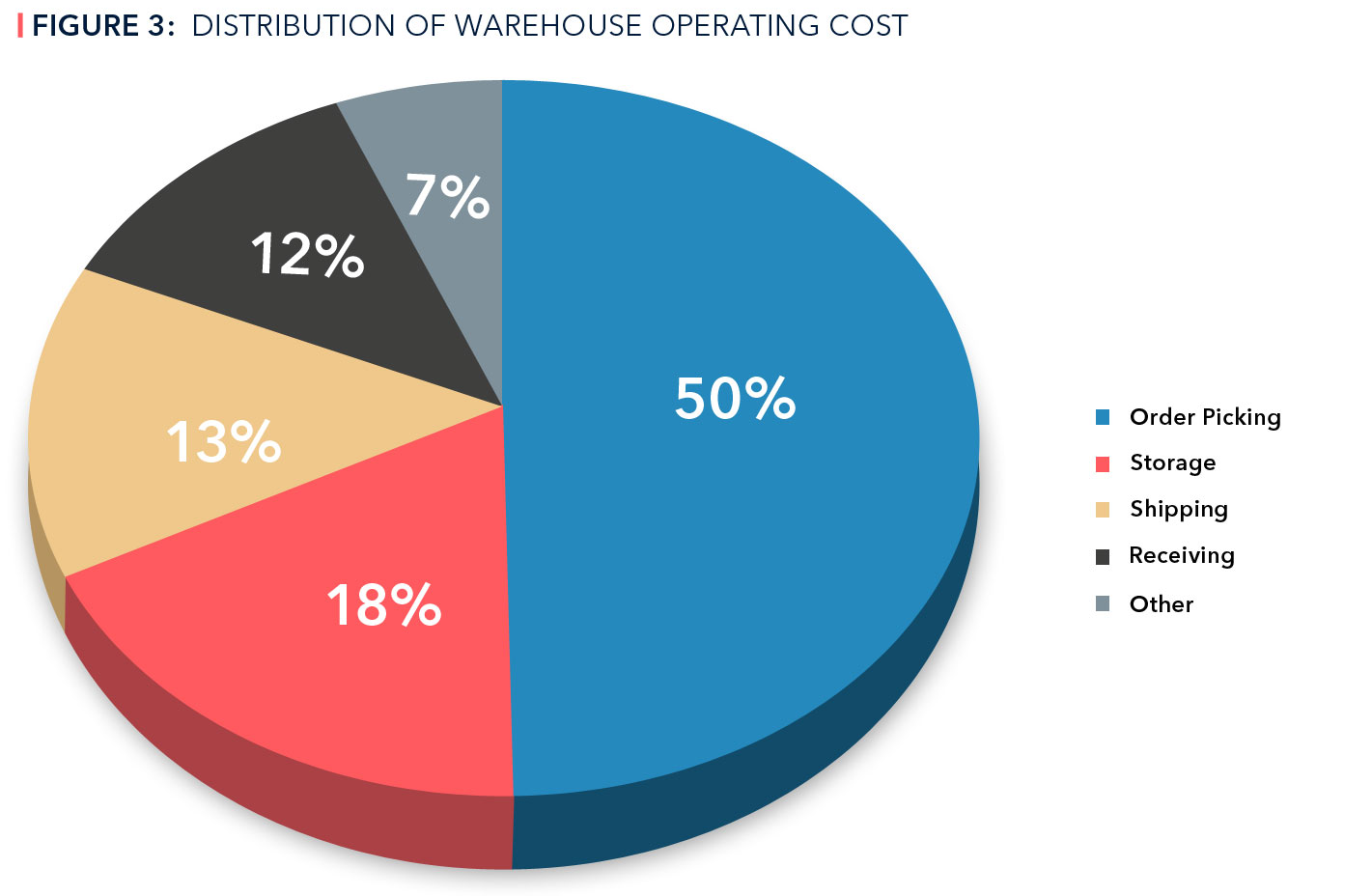

Figure: 3 Moving supply chain through various touch points without a breakdown

This is just one use case of moving material from one point to another. There is a lot more importance given now than ever to automate operations within the warehouse. During an unforeseen situation, operations should still run without jeapordizing customer orders.

Where is the integrated technology?

With all the advancements in technology, a larger number of people still saw the required changes in digitization as a total unnecessary spend. Very few players would have foreseen the need to automate their business operations and integrate them into an overall supply chain. You would often see technologically advanced companies thrive even in difficult market conditions.

What are the success factors to build a strong ecosystem that can lower the possibility of a breakdown in supply chains?

- Thought leadership that encourages adaptability and technology centricity. This is a repeated message given to businesses through many sources that educate leaders, helping them to make the correct decision. A general shift in thought process would help companies move the economy along with their own well-being towards a greater picture of a business process revolution.

- A smart supply chain and end consumer planning mechanism to suggest the right actions. Businesses at different levels of the value chain need to quickly make business decisions to move their operations forward.

- A unified platform that can track operations and notify the status of an operation to relevant personnel at various touch points in the overall supply chain, ensuring continuity in the process and avoiding a breakdown.

- Connected devices through IOT that can pass on signals to automatically perform the next step in the process via a controlled signal from the warehouse operator or supervisor.

- Indicators set for different thresholds on the devices that are automated to gather information early on and proactively handle any issues or problems that could surface.

- Advanced analytics that are more geared towards how the individual business is trending in comparison to how the entire value chain is functioning, basically a business that is part of the value chain has to be in sync with the overall supply chain.

- Integrated technology that enhances the ability to understand the market situation, assess and recommend the business users to make various business decisions such as stocking up inventory, optimizing spend and scale up or scale down of business initiatives.

If larger and midsize companies are progressing towards adopting versatile technologies, smaller businesses that want to emulate the larger market leaders would need adoption of similar platforms.

Figure: 4 Two planners controlling the movement of product remotely using connected technologies.

Obviously the 7 points listed above are not the only factors that can boost trends to the next generation supply chain, but emphasising and being aware of the above can definitely help you decide if you have invested in the right tools that will propel your business forward. The trend would be geared towards better integration of all technological elements, be it collaboration, process automation, connectivity, analytics and recommendations through artificial intelligence ultimately controlled by a person. This infrastructure should cater to small businesses who especially are more spend conscious and may hesitate to do the right thing due to a fear of draining cash.

Intelligent process is not a buzzword, but a necessity to move your business forward and help the world economy be more stable.

Key Takeaways

- It is high time that life is controlled through a remote set of connected devices under the control of real people.

- Man is still the master of a fully connected and well integrated technology that enhances the ability to collaborate and communicate with each other.

- The objective is to make it easy on the individual or business encouraging them to make the decision in favor of business continuity and overall economic development.

Reach out to us for your company’s Digital transformation

Companies with a modern ERP get a 360-degree view of the customer. This holistic view of the customer relationships and their effectivity helps you to better serve customers. You can offer a tailored service to each customer, prioritize your best customers, and automate allocations, fulfillment and discounts for your “A” customers. Improved shipping operations give you the scope for reliable order tracking and shipping notifications.

Companies with a modern ERP get a 360-degree view of the customer. This holistic view of the customer relationships and their effectivity helps you to better serve customers. You can offer a tailored service to each customer, prioritize your best customers, and automate allocations, fulfillment and discounts for your “A” customers. Improved shipping operations give you the scope for reliable order tracking and shipping notifications.