Introduction

For businesses in the pharmaceutical industry, there’s a constant need to manage different challenges such as ever-changing regulations, severe production environment difficulties and complex equipment that can be difficult to maintain. Any equipment downtime could result in production losses and affect drug quality in the value chain, denting the brand image.

When it comes to pharmaceutical manufacturing, production schedules are incredibly demanding, especially when machinery is constantly under operation. These businesses work hard to ensure maximum availability of their assets in order to achieve production efficiency. This requires equipment to perform at full capacity with no downtime to create a competitive production environment.

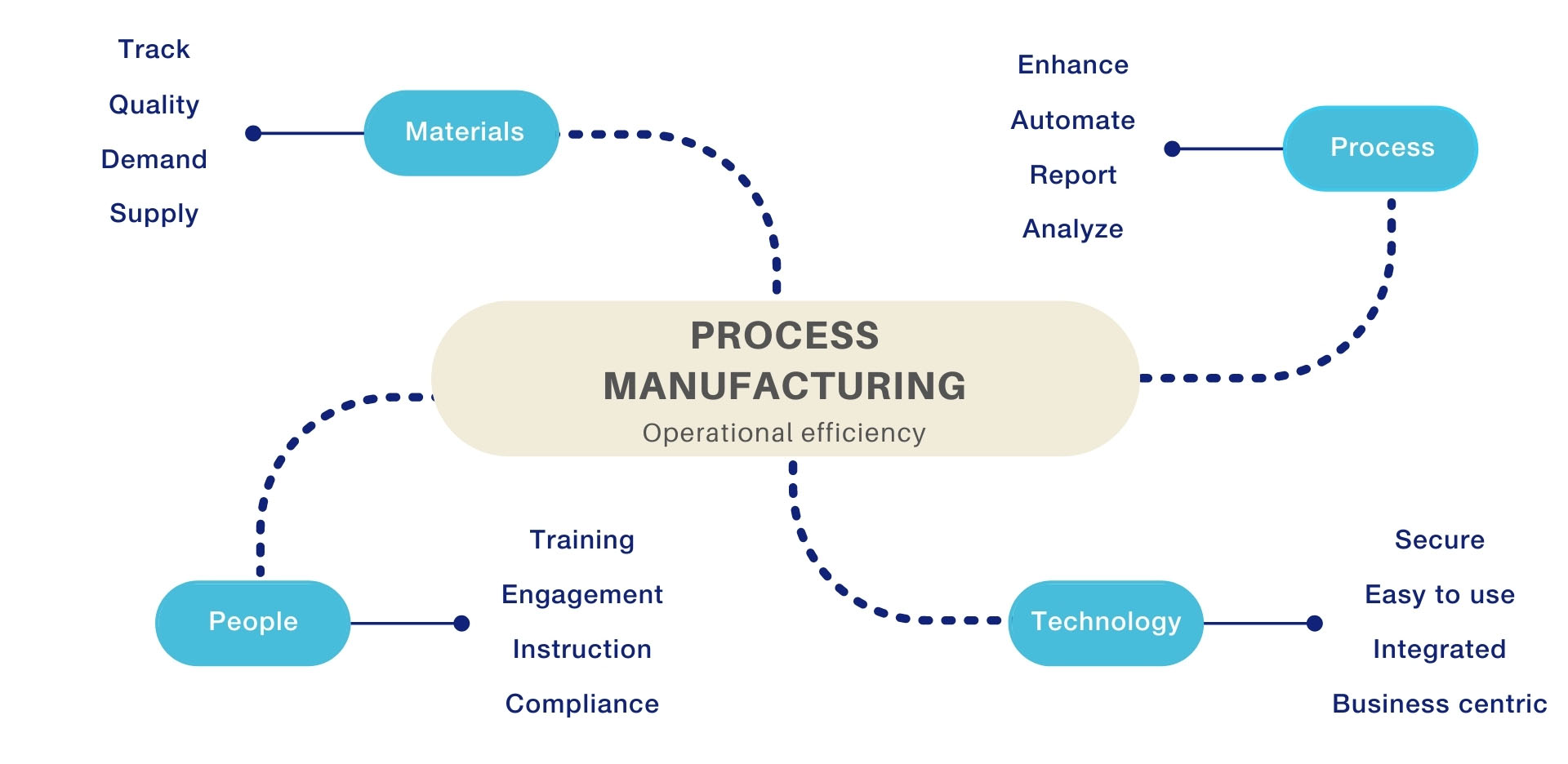

Organizations in this industry looking to maximize their efficiency need to understand a few key points that help present a clear picture of the current state of plant equipment and manufacturing in general.

- Poor equipment maintenance strategies can reduce a plant’s overall productive capacity by 5 to 20 percent.

- Unplanned downtime is costing industrial manufacturers an estimated $50 billion each year.

- Around three-quarters of all the plant equipment in manufacturing is more than 20 years old, which says a lot about the quantum of obsolete equipment and a significant cause of production downtime!.

Understanding equipment downtime, reliability and availability

For manufacturers in the pharmaceutical industry, having fully functional equipment is of utmost importance and means their business can operate normally. Understanding things like downtime, reliability and availability can be just as important if not more.

Scheduled Downtime is important for changeovers, cleaning, tool changes, early shutdowns, personal breaks, or any unplanned events that may occur, such as breakdowns or any repairs that can affect the core business. Equipment reliability is related to the health of equipment and how optimally it performs a task while considering attributes like quality and performance, and equipment availability is the actual time that a machine or system is available for production as a percent of total planned production time.

These are undoubtedly some of the biggest concerns for pharmaceutical manufacturers, but they’re not the only things that these businesses are required to deal with, such as

- Increased downtime: This can lead to Supply chain disconnects, lower production, missed deadlines and increased penalties.

- Spiking maintenance costs: This usually results in businesses reducing maintenance which can lead to complete failures, severely impacting revenue and operations.

- Production dips: Usually caused by gaps in asset or equipment availability, this can halt production and affect the company’s revenue.

- Equipment repair: Without a preventative maintenance plan, businesses are required to perform repairs as needed. This leads to uncertainty when it comes to the status of equipment and prolonged downtimes.

- Equipment replacement: Upkeep is always cheaper than replacement. When equipment isn’t properly maintained replacement costs can easily end up exceeding the total costs of having a basic maintenance plan on board.

- Drug quality of lower standards: Unreliable or under-maintained equipment can unknowingly produce lower quality products leading to fines, penalties and costly recalls.

- Drug safety risks: As equipment ages it becomes easier for contamination to occur, which could lead to additional damages.

- Loss of reputation: Missed deadlines, poor quality and unsafe products can have a severe impact on revenue and brand recognition.

Figure: 1Factors Leading to Poor Equipment Maintenance

A big reason this all matters stems from the U.S. Food and Drug Administration’s (FDA’s) decision to include equipment maintenance as one of the risk-based preventive measures in Current Good Manufacturing Practices (cGMP). With the USDA considering equipment maintenance as a key function of cGMP, it easily becomes one of the most critical factors for pharmaceutical manufacturers’ compliance and will be subject to even greater scrutiny.

Microsoft Dynamics 365 has been a game-changer for the pharmaceutical industry

More and more organizations are better able to control their machinery and minimize “time-to-insight” with Microsoft Dynamics 365 capabilities designed to help businesses gain total control of their data, offering integrated analytics and workflows. Microsoft dynamics for pharmaceutical companies lets businesses speed up the movement of goods, eliminate waste due to costly shelf-life expirations and returns, and improve production efficiency across their entire line. Microsoft Dynamics for pharmaceutical gives companies the ability to achieve the following:

1.Ensuring centralized Quality Control (QC) and regulatory support Organizations can use integrated quality controls and lot traceability to link raw materials through each operation of the production process. This helps accelerate and simplify compliance with regulatory agencies such as the U.S. Federal Drug Administration (FDA).

2.Managing better inventory more effectively Pull inventory in sequence, employing “best before” management, and enabling customer service to ship lots that arrive with the correct amount of shelf life remaining. Employ either first expiry/first-out (FEFO) or first-in/first-out (FIFO) calculations for inventory reservations, picking, reducing inventory and eliminating waste.

3.Conducting extensive audit trails Incorporate electronic signature functionality into existing business processes, providing complete visibility into batch production and audit trails.

4.Meeting GMP requirements Manage electronic quarantines, quarantine release by user and material type, printed material control/ obsolete components, lot control/ segregation, lot tracking, and drug and hazardous material reconciliation.

5.Improving production planning Accurately model the processing of costly ingredients to help minimize overruns and underruns. Shelf-life planning helps account for expiration dates during production and distribution.

6.Protecting recipes and formulas Dynamics 365 helps document various ingredients, storage requirements, manufacturing processes, pH values, particle size, and much more – all with the ability to review at any given moment. D365 lets you set security restrictions to ensure that only approved users are able to make changes, further protecting your critical assets.

Final Thoughts

As the pharmaceutical industry continues to evolve and grow, the need to understand and adopt intelligent technologies like Dynamics 365 becomes more and more apparent. Implementing solutions like Microsoft Dynamics 365 for pharmaceutical and other.

Pharmaceutical manufacturing ERP softwares is the best way for companies to maximize their asset availability and track machine reliability, letting them drive towards increased productivity, higher quality products and enhanced safety assurance.

Get started with one week no-obligation pilot to experience Microsoft Dynamics Finance & Supply for Pharmaceutical