Introduction

We’ve seen quite a few changes in manufacturing over the past two decades, with the next two promising to bring even more exciting things to come. As manufacturing continues to evolve, there are several trends that manufacturers need to be aware of that can either help or hinder the success of their business in the future. Business Intelligence software and tools will play an important role in the future of manufacturing. Microsoft Dynamics 365 F&O plays an important role in how this type of business intelligence information can be analyzed and used to guide business decisions for years to come.

Change in Operations

In today’s business climate, the ability to make data-driven decisions is more important than ever before. This means having access to the right business intelligence (BI) tools for manufacturers. With the right BI tools, manufacturers can gain insights into their operations that would otherwise be hidden. For example, they might discover an increasing trend of machine failures due to a manufacturing defect or determine which materials are most profitable at which price points. With so many BI options available on the market, it can be difficult for companies to figure out which ones will provide them with the best ROI.

Fortunately, Microsoft Dynamics 365 F&O provides a comprehensive solution for any size company looking for a comprehensive BI toolset. Specifically, Microsoft Dynamics 365 has four modules designed to meet the needs of manufacturers across all industries: Operations (also known as Production), Sales, Financials/Accounting, and Customer Service. These modules provide everything from real-time data visualization tools to automated dashboards – all designed with specific manufacturing needs in mind.

A Change in Dynamics

As the world of business intelligence (BI) changes, so does Dynamics 365. This is especially apparent in the manufacturing industry. Microsoft Dynamics F&O provides users with access to data that can help them understand what is happening in their business and take corrective action when necessary.

The software has become an increasingly important tool for manufacturers as they seek to understand their operations and make decisions to improve their bottom line. But, as new technological developments bring a shift from relational databases to machine learning algorithms, it becomes essential for these companies to find a BI platform that can evolve with them. With Dynamics 365’s cloud-based solution being constantly updated; it offers just that functionality needed by these businesses.

How people use BI tools also shifts over time, and with Dynamics 365’s modular design, there are no limitations on how you interact with your data. For example, you can use graphs or tables to show certain information at different times depending on the needs of your business. Suppose a user wants more advanced analytics like neural networks or deep learning capabilities. They are available through add-ons such as Azure Machine Learning Studio or R Server Developer Edition. There is no need to switch systems when you need more advanced analytics; all the options are right within Dynamics.

Business Analytics Tools

Today, data is more important than ever before. This is why more manufacturers are turning to Business Intelligence (BI) tools to help them make sense of the information they’re collecting. BI tools can help you track key performance indicators (KPIs), understand trends, and make better decisions for your business. And this will only become more important as regulations change, competition intensifies, and customer needs evolve.

As things continue to change, it’ll be essential for manufacturers to remain agile enough to adapt quickly – and that means looking at what Business Intelligence tools they’re using now and how their needs might shift over the next few years. For example, there’s been a significant shift from big Data Analytics over recent years as IoT (Internet of Things) solutions become more ubiquitous. As a result, analytics solutions designed for analyzing small datasets have fallen out of favor with larger manufacturing companies.

Industry Challenges

Tools aren’t the only important factor, either. The manufacturing industry is under constant pressure to improve productivity while reducing costs. To stay competitive, manufacturers must adopt new technologies where they can. With so many options on the market, it cannot be easy to know which BI tool is right for your business. Luckily, this question has been answered by a study from International Data Corporation (IDC). IDC’s 2018 Worldwide Semiannual Manufacturing Smart Machines Spending Guide revealed that artificial intelligence-powered analytics would become increasingly important over the next five years.

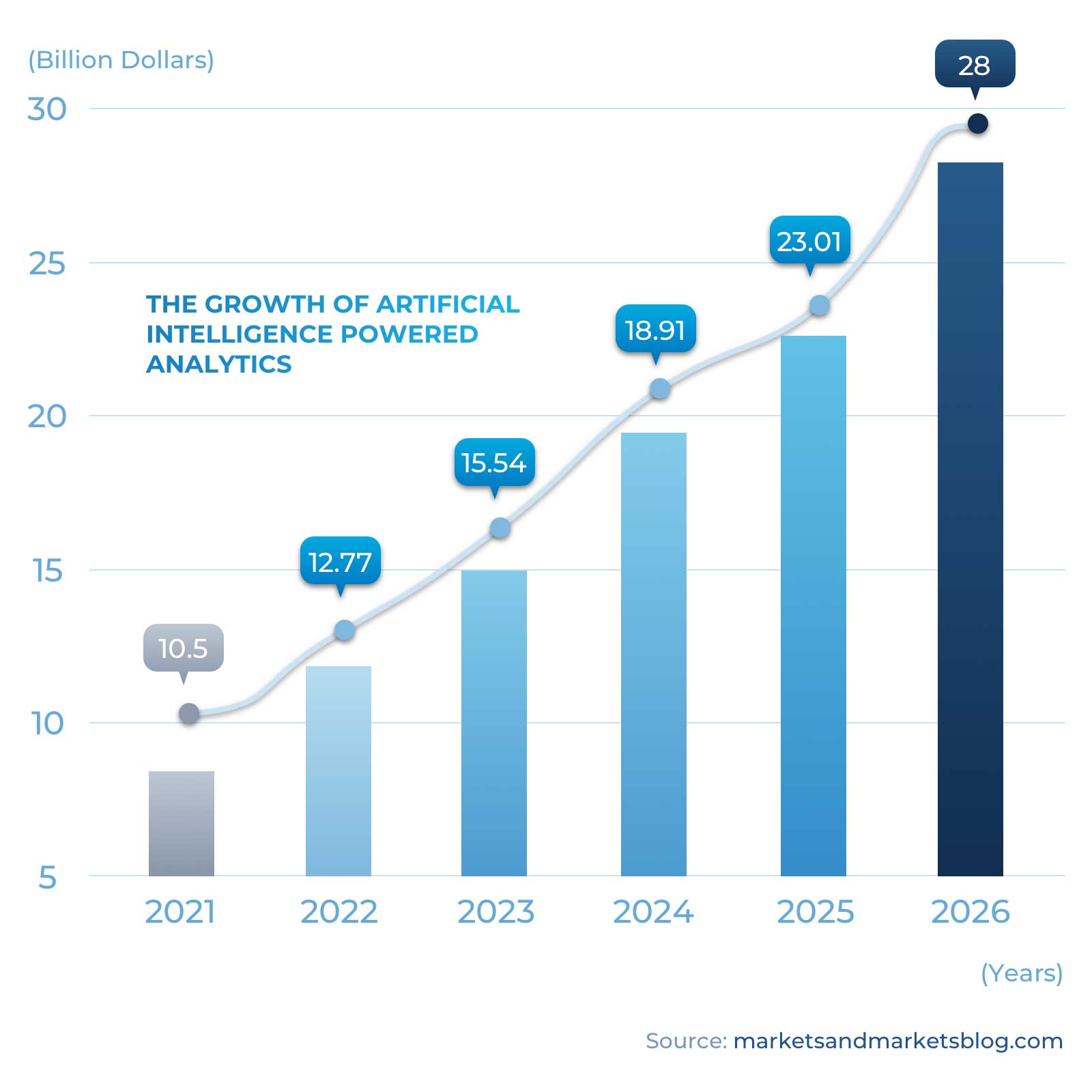

Figure 1:The Growth of Artificial Intelligence-Powered Analytics

According to a report from marketsandmarketsblog.com, The global AI-powered analytics market is projected to grow from $10.5 billion in 2021 to $28.1 billion by 2026 – at a CAGR of up to 21.7% over the forecasted period.

What does this mean for manufacturing? Manufacturers need data about their performance – not just about their products or services but also about their employees and processes. Using intelligent systems like augmented reality or virtual reality combined with artificial intelligence-powered analytics will allow manufacturers to better predict outcomes and make data-driven decisions that drive profitability while improving employee engagement levels.

One organization already doing this is Caterpillar Inc., who implemented digital transformation into its retail stores through an AR application called CatAdvisor. CatAdvisor uses computer vision and 3D point clouds to help retailers sell more products, identify inventory gaps, analyze customer preferences and monitor store traffic patterns. And now Caterpillar is piloting sensors in stores using machine learning and IoT technology to get even more granular insights into customers’ preferences. With these AI-powered solutions available today, there really isn’t any excuse for a manufacturer not to embrace advanced analytics!

The Changing Role of Operations Management

Even operations management in the manufacturing industry is going through significant changes. In the past, the focus was on production efficiency and cost reduction. Today, the focus is on customer needs and market demand. To meet these new challenges, manufacturers are turning to business intelligence (BI) tools and Microsoft Dynamics 365 F&O. Together; these modern solutions enable better insight into product quality, reliability, compliance, and any other KPIs that impact the end customer experience.

Manufacturing companies can also use BI tools to gain insights into their operations with real-time data analysis that can be used for decision-making, such as material sourcing or capacity planning. These solutions allow manufacturers to increase throughput and reduce downtime. For example, a manufacturer may have a bottleneck at one part of the process because they can’t produce enough parts quickly due to the limited availability of materials. With BI, they could track down the problem by looking at lead times, inventory levels, and component dependencies. With this information, they could find alternative suppliers or renegotiate with existing suppliers to free up those materials so they can increase production volume.

The bottom line is this: Manufacturers need to know more about their supply chain than ever before – which means being able to access real-time data at any time in any location.

Power BI Connectors

Business intelligence tools are nothing new. They’ve been around for decades. But what is new is how manufacturers use them to gain a competitive edge. With the rise of Industry 4.0, manufacturers are turning to business intelligence tools to help them make sense of the vast amounts of data generated by their factories. And with the help of included Power BI connectors, integrating these tools into different systems has become incredibly easy.

Power BI Connectors are an innovative way to enhance manufacturing business intelligence data with minimal coding. Rather than manually inputting data into your business intelligence software, connectors automatically export data from other sources directly into Power BI without extensive development. This saves time and money by minimizing any manual processes and gets you up and running faster than ever before. You can choose from various pre-built connectors for industry-leading applications like Microsoft Dynamics, SAP, Salesforce, Google Analytics, Twitter, and many more. You can even build your own if needed.

These pre-built connectors make it easy to create dashboards and reports that analyze and display information from multiple data sources simultaneously. With the advancement of these connections, more and more enterprises have access to enterprise-grade business intelligence capabilities for whatever ERP solution they use.

Schedule a call today for more information to get the ball rolling in your favor.

Putting it All Together

At least for the rest of the decade, the manufacturing industry will undergo some big changes. One of the most significant will be the increased adoption of modern business intelligence solutions, giving manufacturers a view of their operations that was previously unavailable. We should also see Microsoft Dynamics F&O become a more integral part of manufacturing operations. This cloud-based solution will allow manufacturers to manage their business processes more efficiently and effectively.

As manufacturing evolves towards smart factories and advanced automation, keeping up with the latest trends will require a constant commitment to learning new skill sets. This includes expertise in coding and digital engineering design and mastery of traditional engineering disciplines like materials science and mechanical engineering. For the best support, companies should look for partnerships with consulting firms that specialize in training employees across all levels of skill sets needed for today’s manufacturing environment.

Conclusion

As the manufacturing landscape changes, so do the business intelligence (BI) tools that help manufacturers make data-driven decisions. To stay competitive for the rest of the decade, manufacturers should consider ramping up the adoption of modern BI tools that can take advantage of the available wealth of data. Microsoft Dynamics is one of the best tools available to help manufacturers streamline their operations and better use their data.

Partnering with an experienced provider who understands the manufacturing industry and can help you get the most out of your investment with full visibility is important. By working with the right company, manufacturers can better understand their customers’ needs and drive efficiency across all departments. A complete Business Intelligence solution should allow manufacturers to collect, store, analyze, and share information on every aspect of their business.