At a Glance

- Accurately forecasting customer demands allows a company to quickly adapt to changing needs. Leveraging predictive analysis of historical data in demand forecasting models permits better understanding of what customers want.

- Chemical industry decision-makers and inventory managers are now concentrating on short- and long-range demand fluctuations caused by price volatility and changes in supply chain dynamics.

- Top executives can make insightful decisions driven by informed analysis of demand patterns using robust Supply Chain Management (SCM) tools.

Understanding Demand Forecasting

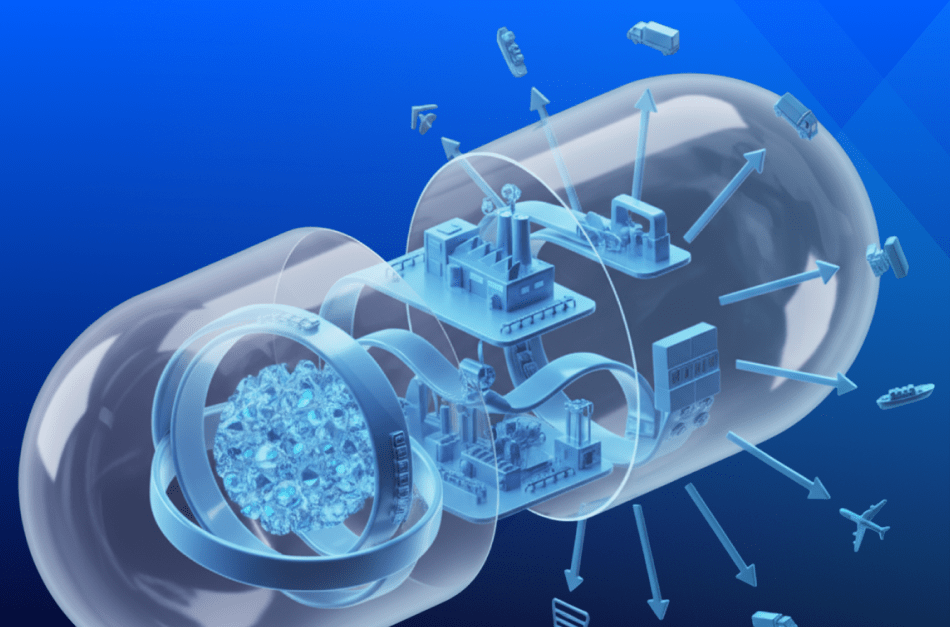

Demand forecasting uses predictive analysis to gauge customer demand patterns based on historical data. Historically, chemical companies use demand forecasting to gauge independent and dependent sales orders. Rapidly increasing global markets and integrated business models show a growing need for better responsiveness and flexibility in demand forecasting. Making these changes helps chemical companies:

- Prepare shipping materials in advance for one-time and complete deliveries.

- Manage inventory while being flexible to accommodate unforeseen demands.

- Sense and predict product demand based on market hierarchy, geography, climate, time zones and other reasons.

- Stand out in the market by consistently delivering at competitive prices.

Understanding historical demand and accurate inventory management plays a key role in forecasting sales. It ensures adequate inventory. Improperly managed inventory impacts everything from shipments to sales. Companies are very reactive about their inventory planning when resources are not allocated properly. Continually reprioritizing orders throws off historical demand tracking. Adding an unexpected order can lead to big problems.

A recent poll by Deloitte with chemical executives indicates that more than 20% of total US chemical sales will be driven by business-to-business (B2B) e-commerce in 2021.

Accurately forecasting inventory helps firms understand what they have. It also helps visualize the sales pipeline. With accurate demand forecasting, a plant can take measured risks and make informed decisions causing higher profits.

Demand Forecasting Challenges

Chemical companies often struggle to leverage huge volumes of data. Not understanding and using the data effectively can cause incomplete interpretations and communication errors.

The supply chain may have multiple stakeholders using different systems for enterprise resource planning (ERP), data management (DM) and supply chain management (SCM). Demand forecasting using these different systems often causes duplicate information and loss of crucial data.

Failing to use an integrated, sophisticated demand forecasting system limits a company’s ease of use and its ability to customize the software for its unique needs.

Figure: 1Demand Forecasting Challenges in Chemical Industry

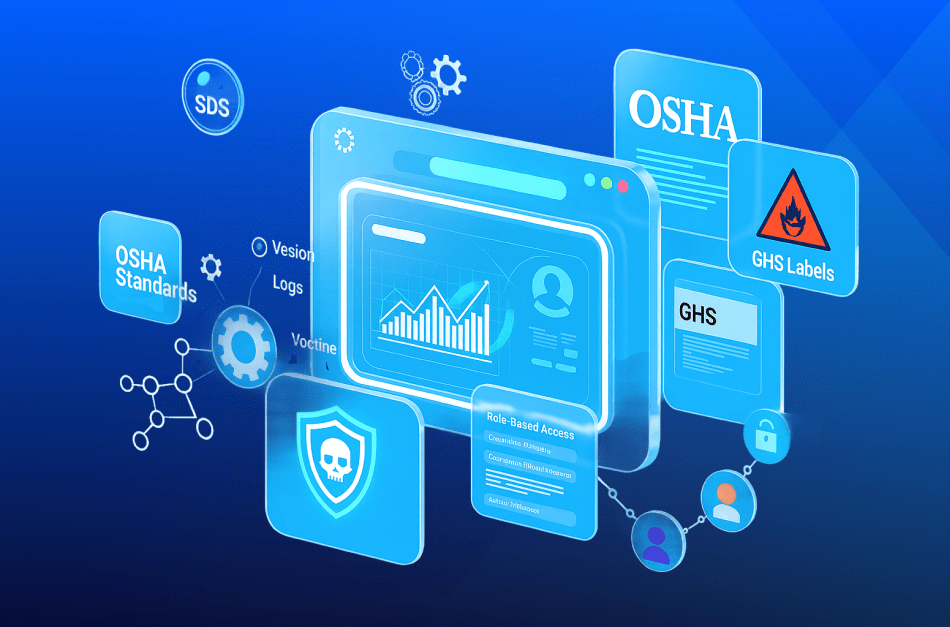

Demand Forecasting in Microsoft Dynamics 365

Microsoft Dynamics 365 Supply Chain Management (SCM) helps businesses adjust forecasts and view key performance indicators (KPI’s) more efficiently. Companies using this product can see demand trends and then adjust forecasts. The new forecasts seamlessly are used in inventory planning. By removing outliers, Dynamics 365 enables accurate measurements.

Dynamics’ Supply Chain Management tool follows a comprehensive flow for demand forecasting:

- 1.System gathers historic transactional data.

- 2.Machine learning uses the data to generate forecast and insights.

- 3.Collected data provides forecast visibility while allowing forecasts adjustments.

- 4.Approved forecasts are then authorized.

Figure: 2Demand Forecasting in Microsoft Dynamics: How it Works

Microsoft Dynamics 365 SCM helps manage these complex demand patterns and improve inventory planning. Its features include:

- Integrating Planning Optimization using demand forecasts to make informed decisions for master plans.

- Creating, generating or importing the demand forecast based on operational models and company requirements.

- Customizing demand forecasts that streamline the process by reducing intercompany orders and considering customer forecasts.

- Increasing accuracy and margin with lean demand forecasting.

- Graphing and creating interactive demand forecasts for real-time feedback anywhere on the trend line.

- Seamlessly applying the demand forecasting tool with existing ERP. This harnesses data and generates accurate forecasts for improved inventory control and bottom lines.

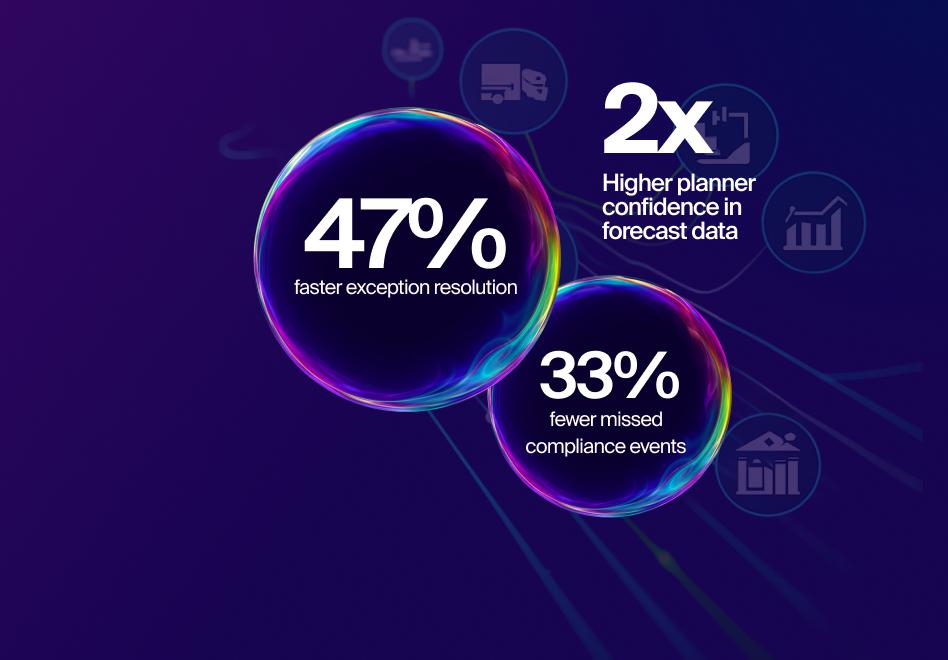

Chemical companies can better predict demand by fortifying their IT infrastructure with the right tools. Using software that’s easier to use, more accessible and has greater accuracy enables them to improve their inventory planning. Integrated solutions like Microsoft Dynamics 365 provide a robust and complete demand forecasting tool, enabling businesses to set up and maintain optimal inventory control.

Key Takeaways

- Demand forecasting in the chemical industry needs to move forward from conventional, spreadsheet-based models and tools to newer, more agile digital systems.

- Microsoft Dynamics 365 offers chemical companies the ability to forecast inventory levels more accurately through visual, customizable and interactive features.

- Increased focus on accurate demand forecasting helps chemical companies avoid stock-outs or over-stocking. It improves profits, strengthens supply chains and elevates overall customer satisfaction.

To learn more about implementation of demand forecasting in your chemical company, book a consultation with Xcelpros.