Last updated 2025 — backed by new analyst insights, supply chain practitioner feedback, and system-level learnings.

When we first published this blog in 2018, On-Time Delivery (OTD) was already a well-established KPI. It was simple. Clear. Measurable. And it exposed one universal truth: if you can’t deliver what you promised, on the date you promised, you lose trust.

That hasn’t changed.

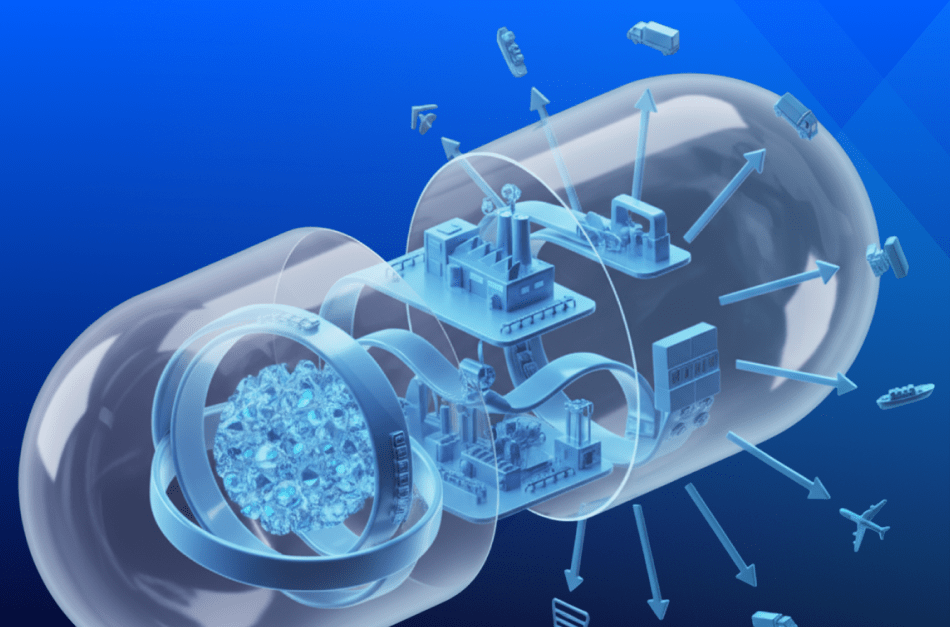

What has changed is everything around it: supply chain velocity, system interoperability, labor volatility, and customer expectations—especially in industries like chemicals and pharmaceuticals where batch-level traceability and regulatory accountability come with every shipment. OTD hasn’t faded into the background. In fact, in the age of AI-powered planning, it’s quietly become even more valuable.

OTD didn’t fade. It evolved.

But the way we calculate it, act on it, and fix it? That’s evolving.

Why OTD Still Matters—And Always Will

At its core, OTD is a signal of supply chain health. It reflects planning accuracy, cross-team collaboration, and executional strength. If you’re consistently late, it’s rarely a symptom in isolation. It points to broader, systemic disconnects—between procurement and production, sales and logistics, or planning and reality.

For industries managing tight margins and heavy compliance burdens, being late isn’t just about losing goodwill. It can mean rejected shipments, regulatory scrutiny, or even production shutdowns. And for your highest-value customers—the ones contributing 70% of your revenue—the bar is even higher. Miss once, and they escalate. Miss twice, and they start exploring alternatives.

What’s Different Now?

Since 2020, the very definition of “on time” has been reexamined. The pandemic exposed how brittle our just-in-time models were. And while many organizations have recovered, the scars are still visible in the form of fragmented planning systems, tribal knowledge workarounds, and a growing reliance on manual workarounds when visibility fails.

Today, OTD is no longer just a logistics metric—it’s a business continuity indicator.

Here’s what’s changed:

Speed of demand fluctuations.

Volatile order patterns are now the norm, not the exception. Manual planning processes can’t keep up.

Supplier variability.

Tier-2 and Tier-3 suppliers remain a blind spot for many. Missed lead times upstream lead to missed deliveries downstream.

Data overload without insight.

Teams have access to more data than ever—but without integration across ERP, MRP, and production systems, that data is often unusable when it’s needed most.

Expectation inflation.

Amazon-like service expectations have reached B2B. A 90% OTD rate is no longer good enough in many sectors.

According to a 2024 study by Supply Chain Quarterly, 64% of manufacturers surveyed say OTD is harder to achieve now than it was five years ago—despite having more tools at their disposal.

Managing OTD in a Modern Supply Chain: What It Looks Like Today

In the past, improving OTD was a game of operational cleanup. You’d look at your last 100 late orders, investigate root causes, and fix the process gaps. That still matters—but it’s not enough.

Now, the conversation starts earlier and runs deeper.

What Leading Manufacturers Are Doing Differently

-

Shifting from reactive to predictive.

AI-driven planning tools now monitor real-time inventory levels, supplier performance, and production bottlenecks. Instead of waiting for a late delivery to occur, teams are alerted the moment a deviation is likely. A delay in quality clearance? A deviation in material yield? A production stoppage two machines away? Smart systems flag it before it becomes a missed delivery.

A delay in quality clearance today becomes a missed delivery tomorrow—unless your systems see it first.

-

Connecting systems for end-to-end visibility.

Manual handoffs between planning, quality, and logistics functions introduce latency. Modern supply chains use connected ERP-MES-QMS architectures, with centralized dashboards that expose blind spots instantly. These dashboards now power proactive interventions—not just reports after the fact.

-

Building resilience into planning parameters.

Safety stock levels, reorder points, and batch scheduling are being recalibrated using data models trained on historical disruptions, not just average demand. These models account for lead-time variability, labor availability, and even weather patterns that impact transport windows.

What the Data Shows

At XcelPros, we revisited over two dozen OTD-related client engagements across pharma and chemical verticals since 2021. The patterns were striking:

- 78% OTD – average for companies with disconnected planning & QMS systems.

- +15 pts avg to 93% – average OTD improved from 78% to 93% within 6–8 months

- 30% fewer late-stage delays – for organizations that adopted barcode/RFID during high-volume periods.

It’s not just about doing the basics better. It’s about upgrading the definition of “basic.”

But It’s Not Just About the Tools

Yes, the right systems are critical—but mindset matters just as much. Organizations still stuck in legacy workflows often treat OTD failures as isolated incidents. In reality, they’re signals that trust in planning systems has eroded.

We’ve worked with production leads who bypass MRP entirely. Procurement heads who bulk-order to “play it safe.” Shipping managers who manually re-sequence deliveries in disconnected systems. Not because they’re reckless—but because they’ve been burned before.

It’s tribal knowledge stepping in where systems fall short. But while it may save the day short-term, it doesn’t scale—or prevent recurrence.

To improve OTD today, leaders must reestablish confidence in systems. That means fixing upstream data quality, reinforcing training on SOPs, and ensuring feedback loops between what was planned, what happened, and why.

From Legacy KPI to Live Indicator

On-time delivery has stood the test of time—not because it’s easy to measure, but because it reflects everything behind the curtain. Planning quality. System trust. Team coordination. And customer accountability.

What OTD Means in 2025

But in 2025, OTD isn’t just a reflection of past performance—it’s a live indicator of what’s working across your supply chain, and what’s not. That makes it more than a metric. It makes it a mandate.

If your teams are still relying on disconnected workflows, tribal knowledge, or delayed reports to manage on-time delivery—there’s a better way. One that doesn’t just improve fulfillment percentages, but creates predictability your customers can count on.

OTD Modernization Starts Here

Still managing OTD through retroactive reports or siloed systems?

Let’s talk about modernizing with AI-powered visibility, real-time coordination, and traceable delivery performance.