At a Glance: Why On-Time Delivery (OTD) Matters

According to Harvard Business Review research, increasing customer retention rates by just 5% can increase profits by 25% to 95%, highlighting the critical importance of meeting customer demands on time.

A 2024 industry report showed that 69% of consumers are less likely to shop with a retailer in the future if an item they purchased was not delivered within two days of the promised date. Additionally, 17% of customers said they’d stop buying from a retailer after one late delivery, and more than half would abandon a retailer after two or three late deliveries.

The most important step towards achieving optimal on-time delivery metrics involves solving operational issues at the grass root level. Organizing a well-structured Daily Operational Meeting (DOM) not only increases productivity but also improves customer service.

As of 2024, 56% of online consumers between ages 18-34 expect same-day delivery, with 61% of all consumers willing to pay more for same-day delivery, while 80% of shoppers want same-day shipping.

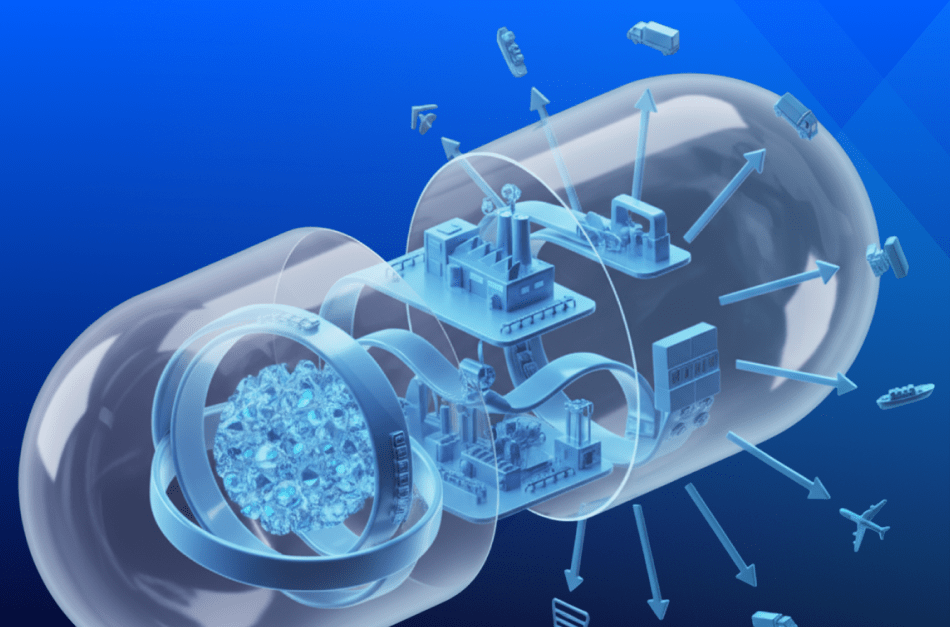

Implementing a modern ERP solution will streamline your business processes, meet customer requirements, and ensure on-time delivery.

In Part 1 of this series (On-Time Delivery in 2025: Still the KPI That Defines Operational Trust), we brought out challenges like lack of communication across departments and inefficient business processes that hinder the on-time delivery of products.

As discussed in the prior blog, a few Key Performance Indicators (KPIs) that are critical in measuring delivery performance in logistics and supply chain operations are:

- On-Time Delivery (OTD) or On-Time Performance (OTP)

- Delivery in Full (DIF)

- Delivery in Full On-Time (DIFOT), On-Time Delivery in Full (OTDIF) or even On-Time in Full (OTIF)

- Cost as a percentage of sales

- Inventory Turns (days)

Consistent problems with OTD not only affect your business and its reputation, but also customer relations and the company’s supply chain. On-Time Delivery in Full (OTDIF) can be impacted due to a variety of reasons. To name a few:

- Bad forecasts

- Supplier delays

- Quality delays

- Product rejections

- Other technical and operational issues such as the ineffective Material Resource Planning (MRP) system and outdated ERP system.

According to a 2024 McKinsey report, CPG companies can reduce costs by up to 30 percent through strategic cost management and resource reallocation, while poor on-time and in-full (OTIF) performance continues to impact profitability. More than half of CPG companies reported that retailers have tightened their OTIF requirements by narrowing delivery windows and increasing fines for noncompliance.

Steps like identifying the root cause of late deliveries and prioritizing to avoid them coupled with an effective plan to get rid of such problems help your organization increase your on-time delivery metrics and productivity.

Kroger, the grocery giant, is known to fine suppliers $500 for each order that is delayed by 2 days or more. Walmart has been very stringent on its delayed receipts from its suppliers. It has charged suppliers upto 3% of the purchase price for every order delivered that has not been delivered on time – early, late or partial. –McKinsey & Company

ERP Helps You Achieve On-Time Delivery (OTD) KPI

If you are using spreadsheets to keep track of your supply chain, it’s time for you to switch to automation as manual processing is cumbersome and error prone, costing you millions. Deploying a modern ERP system can boost your supply chain efficiency: from better inventory control to faster delivery of goods, to improved productivity.

A good modern-day ERP ensures stronger supplier relationships, streamlined shipping operations, and better customer communication through reliable lead, opportunity and quote tracking. The software offers fundamental benefits such as reduced lead-time, on-time shipments, and a reduction in cycle time. Reduced lead time is a critical parameter as non-availability of an item can create issues such as missing delivery schedules and losing customers to your competition.

Real-time data analytics helps you to better manage inventory levels and order fulfilment rates.

According to a 2023 global supply chain survey, data analytics is helping business leaders achieve DIFOT rates of 96% or above, which is at least 7% higher than the industry average. A 2024 survey found that 96% of supply chain leaders agree that end-to-end understanding of supply chain operations combined with data analytics skills (59% prioritize this) is the most important knowledge for supply chain teams.

ERP has really helped with a better distribution of information across the internal teams within our company.

Success Story: How to Improve OTD, Practical Steps

One of our clients, a US-based manufacturing company, initiated an upgrade of their existing ERP software. The upgrade was imperative as the system was hurting overall profitability and enterprise-wise efficiencies. There was a lack of visibility of data, most communication was manual, inventory was all over the place, resources & human capital was untracked from a costing perspective etc. Within 6 months of upgrading their ERP system to a modern cloud-based system, their on-time delivery improved by 28% as the system was able to track each step of the operation with enhanced visibility of inventory and supply chain.

Key Takeaways for Supply Chain Leaders

Finally, most companies manage OTD not just as a single date but instead as a range of dates – missed (X) or expected (Y) dates.

- A structured operations meeting led by a strong leader can do wonders for OTIF. Resolving operational issues at a micro level is essential.

- An effective ERP software solution helps drive efficiencies across the board.

- A metric that drives customer satisfaction will drive long-term customer retention and revenue for your organization.

Get the clarity you need to deliver on time, every time.