At a Glance

- The biotech industry is witnessing unprecedented demand on many fronts. Companies are looking to invest in fast-paced innovation, systematic storage of massive research data, analysis of humongous databases, and meticulous management of the business processes. AI-enabled applications play a crucial role in meeting these demands.

- Machine learning, robotics, informatics, and AI branches can help in expanding the horizons of the biotechnology industry and move towards newer possibilities.

AI-led Transformation of the Biotech Industry and Its Positive Effects

The Biotechnology industry is currently relying heavily on storage, filtration, analysis, and the exchange of data. Massive databases are maintained by biotechnology companies and various health organizations worldwide. Drug manufacturing, chemical analysis of different compounds, sequencing of RNA and DNA, enzyme studies, and other similar biological processes require the strong support of computerized tools and applications to gain pace and reduce manual errors.

Today, the world is witnessing an unprecedented health emergency in terms of the Coronavirus pandemic. Economies are collapsing, countries are under lockdown, and all hopes are pinned on the biotechnology industry to come up with a safe, effective vaccine in the shortest possible time frame. The use of Artificial Intelligence in biotechnology and related applications play a crucial role in managing biological processes, boosting medicine production, handling supply chains, and taking care of the pool of data for this industry.

Increased and better predictability for both structured and unstructured data helps companies in planning their operations accordingly for enhanced productivity and a faster pace of work.

Figure 1Applications of Artificial Intelligence in Different Fields of Biotechnology

Leading biotech companies are investing in advanced AI tools to:

- Analyze research data

- Accelerate vaccine development

- Classify the target market and demographic

- Identify the right ingredient to produce the vaccine

86%of current or planned AI spending is in customer-oriented areas, with marketing and sales leading the pack

$1.2 TNestimated additional revenue/ shifting revenue driven by AI in three years

While there are still many unknowns when it comes to a successful coronavirus vaccine, this US biotech firm has applied artificial intelligence to accelerate the process of vaccine development.

The biotechnology sector will leverage artificial intelligence and its related applications with vigor in the coming years. According to an article for Medium by Melanie Matheu, Ph.D., the next generation of therapeutics entering drug pipelines will contain targets selected by AI screening, likely improving the 86% clinical trial failure rates for small molecules.

The biotechnology industry has various sub-sectors ranging from human life sciences, food industry, agricultural biotechnology, animal biotechnology, and industrial applications. These branches can all leverage the advancements seen in artificial intelligence and machine learning related applications developed in the past decade, including five key AI trends that will transform the biotechnology industry, listed below.

The Application of AI is Shifting More Towards Knowledge Workers

79%agree AI and related technologies are having a transformational impact on workflows and tools for knowledge workers

80% say that placing powerful AI-fueled application in the hands of knowledge workers is critical to productivity and performance

84% agree AI streamlines processes, freeing knowledge workers for move creative, intuitive and laterally thinking activities

Here are 5 key AI trends that will transform the biotechnology industry

01Boosting Innovations: From Lab to the Market

The past decade has witnessed the need for fast-tracked innovation, production and deployment of medicines, industrial chemicals, food-grade chemicals, and other biochemistry-related raw material. AI in Biotech plays a crucial role in boosting innovation not only in the laboratories but also throughout the lifecycle of a medicine or chemical compound (right to the point where it reaches the market). Based on the target market, AI-based tools and applications help in developing the structure of molecules. Machine learning, a subset of artificial intelligence, helps in calculating permutations and combinations of various chemicals to know the right combination, without having to perform the experiments in the lab through manual processes. The use of artificial intelligence in biotechnology is bringing innovations that can help in predictive analysis to forecast the demand for a particular medicine or a chemical in the market. AI in Biotech can also help in managing the smart distribution of the raw material required by the biotechnology industry through the use of cloud computing.

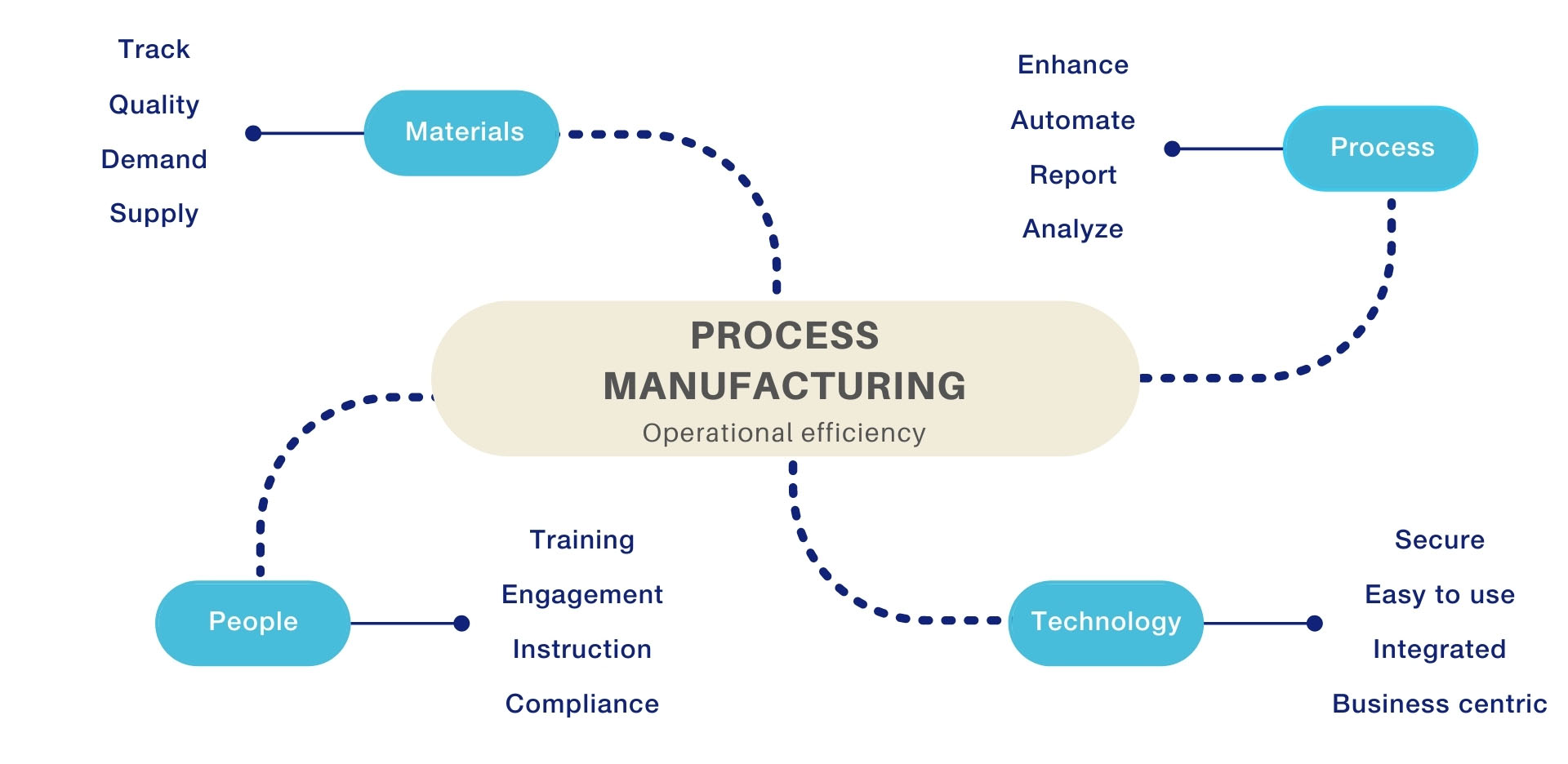

Figure 2Functionalities of AI in Biotech Industry

02Open Source AI Platforms: Faster Data Analysis

Scientists across the globe are looking at AI programs that can take over the tedious nature of data maintenance and data analysis. Tasks like gene editing, enzyme compositions, chemical studies, and such crucial informatics are analyzed systematically for faster and more accurate results. Open-source AI programs such as CRISPR libraries and H2O.ai are playing an essential role on this front by relieving lab assistants of repetitive tasks like data entries and analysis. By eliminating manual functions for healthcare providers and scientists, they can better focus their efforts on innovation-driven processes and it will be possible with the use of artificial intelligence in biotechnology.

03Pushing the Boundaries of Agricultural Biotechnology: Increasing Quality and Quantity

Biotechnology plays a crucial role in genetically modifying plants to develop more and better crops. AI-based tools become essential to this process of genetic modification to study the features of the crop, to note down and compare qualities, and to forecast plausible yield. Apart from these tools, robotics, an arm of artificial intelligence, is being used by the agricultural biotechnology industry for packaging, harvesting, and other essential tasks. AI in biotech also helps in planning the upcoming patterns in the movement of material by combining weather forecasts, data on the nature of farmlands, and the availability of seeds, manure, and pesticides.

04Discovery of New Drugs and Vaccines: Shrinking the Timeline

In a globalized world, newer diseases have a fast way to spread across continents. Thus, the biotechnology industry is at a race against time to develop newer drugs and vaccines to be able to contain such diseases. Artificial intelligence and machine learning are vital in speeding up the process of recognizing the right molecules, helping in synthesizing them in the labs, data analysis for efficacy, and it supplies to the market. Operations, which would usually take 5-10 years, have now been shrunk to 2-3 years with the use of artificial intelligence in biotechnology.

Figure 3Subsets of Artificial Intelligence in Biotechnology

05Facilitating Global Connect: Sharing Biotechnology Developments Worldwide

AI platforms are resourceful in letting scientists across the globe have access to imperial data regarding newer medicines and other industrial developments. Many machine learning tools are assisting scientists in decoding data and understanding patterns of a particular disease in a far-away country and utilizing it to build analytical models for their geography. The accuracy of scientific models has increased by several folds, after the introduction of AI in Biotech.

While these are the key trends, AI and related tools are helping in transforming the biotechnology industry in many ways. Coming times will see the use of artificial intelligence in biotechnology for the betterment of humankind by the progress it facilitates in the fields of biosciences and technologies.

The power of integration of Microsoft’s AI with Microsoft Dynamics 365 helps biotech companies get over the industry’s pressing challenges. Hindrances such as resource management, stringent regulations, quality management, etc., and establishes seamless workflow by ensuring unified data sharing, visibility, and connectivity across diverse channels and operations so that teams better communicate.

This collaboration with the use of artificial intelligence in biotechnology helps your company to

- Achieve regulatory compliance

- Gain visibility into your supply chain management

- Track and control your inventory with accuracy, and

- Integrate industry best practices for corrective and preventive action

Finally, the digital transformation achieved with the Full Microsoft Suite gives you data in real-time to make smart and actionable business decisions to spur company growth.

Key Takeaways

- The biotechnology industry has progressed significantly with the application of AI and related computerized tools.

- Be it medical, industrial or agricultural biotechnology, AI, machine learning, and robotics play critical roles in pushing the boundaries of possibilities in these fields.

Using our years of industry experience in the biotech, life sciences, and pharmaceutical industries, we suggest and help our customers with the best ways to reduce costs and mitigate implementation risks. We work with you throughout the implementation, so that you can quickly identify, address, and record any production, shipping or quality control risks, events, and complaints. A personalized, flexible D365 dashboard equips your teams to trigger a hold on products throughout the supply chain autonomously, launch nonconformance reports, send notifications to managers when test results hit a certain threshold or when a specific research milestone deadline is compromised.

Reach out to us for your company’s Digital transformation