At a Glance (2025 realities)

| OSHA Violation Category | Maximum Penalty (2024) | Maximum Penalty (2025) | Key Characteristics |

|---|---|---|---|

| Other-than-Serious | $16,131 | $16,550 | Direct relationship to safety but unlikely to cause serious harm. Fines may be reduced by up to 95% based on factors like good faith. |

| Serious | $16,131 | $16,550 | Substantial risk of serious injury or death from a known hazard. Fines may be reduced based on good faith efforts. |

| Willful | $161,323 | $161,550 | Employer knowingly committed a violation or acted with plain indifference to employee safety. Good faith is typically not a factor in fine reduction. |

| Repeated | $161,323 | $161,550 | Cited for a violation that is the same or highly similar to a previous citation within five years. Penalties are multiplied for subsequent offenses. |

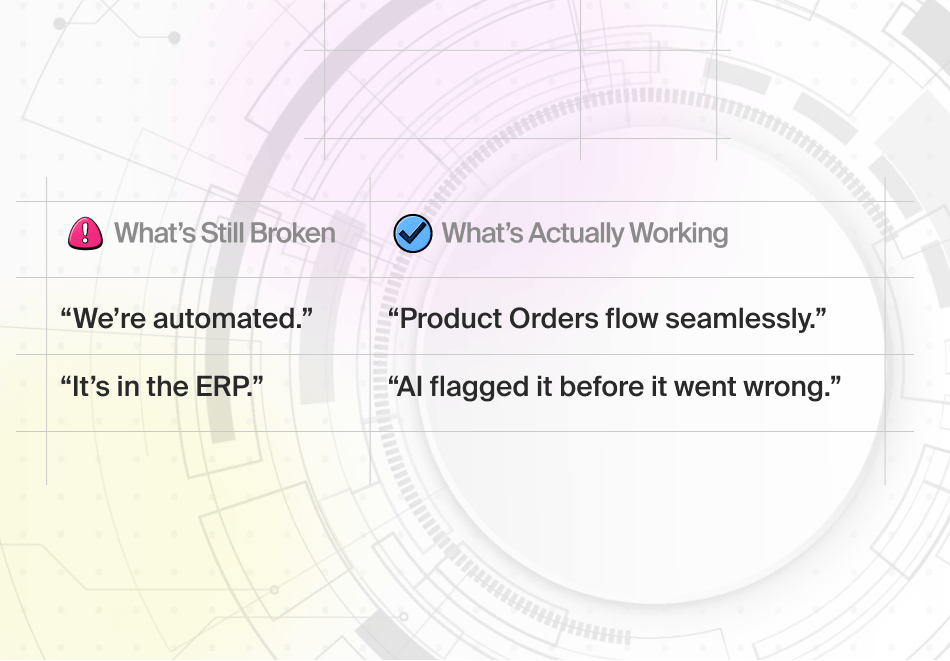

Compliance ERP vs. Legacy Systems in the Chemical Industry

A decade ago, many chemical manufacturers viewed ERP as record-keeping, but today compliance ERP and chemical compliance software have become central engines for operational safety. In 2025, it’s a central compliance engine, a connected ecosystem, that ties OSHA Hazard Communication (HazCom) requirements, GHS labeling, safety training, and access control into a single, real-time platform.

The stakes are higher than ever. Penalties for willful violations have more than doubled in some states. Regulators expect faster evidence retrieval, live process traceability, and role-based clarity in hazardous material handling. The companies that succeed are the ones that stop treating compliance as a file cabinet function and start treating it as an operational performance metric.

From SDS Compliance to Real-Time Hazard Intelligence

Unlike traditional SDS management, ERP-driven chemical data management systems update sheets automatically, ensuring version control and compliance consistency. Today’s ERP-driven SDS workflows do more:

Dynamic Updates

An ingredient change in one formulation triggers automatic SDS and label updates across all affected SKUs, with instant downstream version control.

Multi-Channel Access

QR codes on labels pull the latest SDS directly from the ERP, whether scanned on the plant floor, in transit, or at a customer site.

Role-Based Gatekeeping

Access to hazardous substances is automatically restricted to certified, trained staff. The ERP cross-checks training validity in real time via LMS integration before issuing approval.

This isn’t theoretical, in one chemical plant retrieval time for SDS during a regulatory inspection dropped from 25 minutes to under 60 seconds after ERP integration. That alone can mean the difference between passing and failing an audit.

Building a Connected Chemical Compliance System

Modern chemical compliance systems, powered by ERP and compliance management software, go beyond individual features to provide an integrated ecosystem. By integrating SDS, training, labeling, and audit readiness into a seamlessly connected ecosystem, they transform compliance from a post-operational task into an integral part of the production process.

Instead of siloed systems, ERP-driven ecosystems provide a real-time digital safety net—ensuring that every update, approval, and access check reinforces operational safety and regulatory alignment across the enterprise.

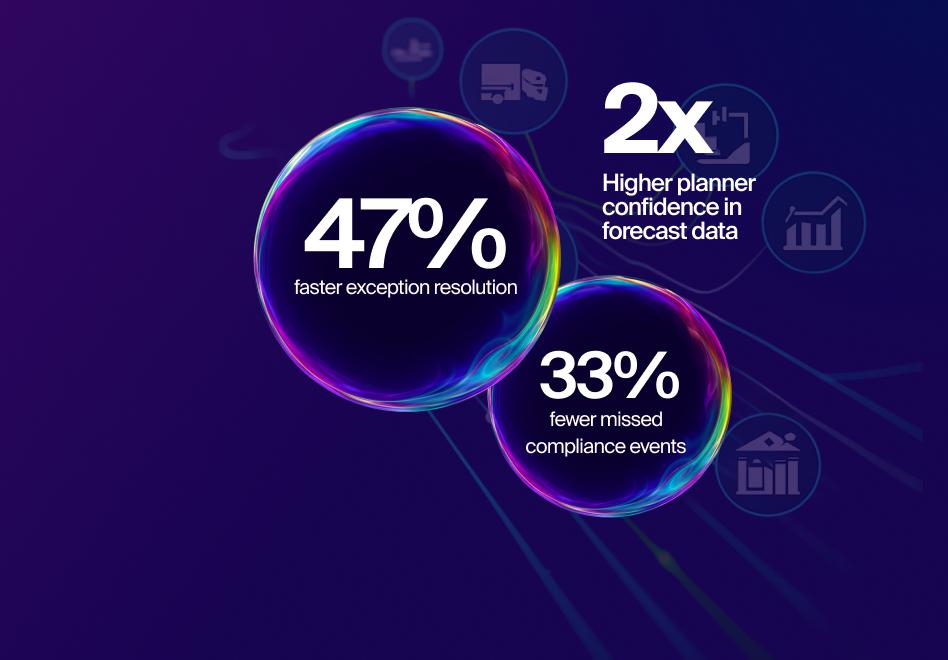

ERP + MES + GenAI = Predictive Compliance

Forward-looking chemical manufacturers are linking ERP and MES to create compliance-ready production environments. By adding GenAI-driven insights, systems can now:

- Flag training gaps before a scheduled audit

- Suggest preventive maintenance schedules for equipment tied to hazardous processes

- Integrated PPE ERP capabilities recommend updated protective equipment protocols when OSHA or GHS standards shift, closing gaps in worker safety compliance

- Generate “risk readiness dashboards” so leadership can see immediately where exposure exists before the regulator does

One chemical distributor we worked with used this combined approach to cut OSHA corrective action timelines from 21 days to just 6.

Why ERP Security Matters in the Chemical Industry

ERP security in the chemical industry ensures that hazardous data, SDS records, and compliance workflows are protected across region-specific regulatory environments. An ERP that isn’t configured for SDS, HazCom, and GHS workflows from the ground up creates hidden risk:

- Incomplete hazard labeling for export shipments

- Mismatched SDS data between facilities

- Missed training renewals for high-risk roles

Modern compliance ERP solutions ensure GHS labeling accuracy with ERP integration, where every formula change instantly updates hazard classifications and SDS sheets across facilities.

Every formula change instantly updates hazard classifications, pictograms, and SDS sheets across facilities, eliminating manual rework and ensuring global consistency. Automated version control ensures that the latest SDS is always available, while integration with labeling systems reduces the chance of costly misprints or outdated hazard symbols.

Working with a vendor who understands chemical manufacturing means your ERP is built to speak compliance fluently, not just store it.

ERP Compliance for Chemical Industry OSHA Standards

The conversation has shifted from “How do we avoid fines?” to “How do we use compliance as proof of operational excellence?”

- Investors see it as a proxy for governance quality

- Customers see it as a trust marker

- Regulators see it as an indicator of cultural maturity

An ERP built for compliance in the chemical industry not only tracks OSHA standards and CAPA readiness, but also turns audit prep into a source of operational credibility.

Bottom Line

The era of treating ERP as a compliance archive has ended. In the modern chemical industry, managing compliance is no longer a reactive burden but a strategic imperative. A purpose-built ERP system now acts as the central nervous system of operations, seamlessly orchestrating people, processes, and data into a connected ecosystem that delivers real-time safety intelligence.

This transformation makes regulatory adherence a built-in operational reflex: OSHA inspections, automated GHS labeling, SDS updates, hazardous material tracking. By shifting from manual, after-the-fact checks to automated, ecosystem-wide visibility, chemical manufacturers don’t just respond faster – they stay audit-ready year-round.

Most importantly, compliance stops being a cost of doing business and becomes a source of sustained competitive advantage and profitability. With the right ERP foundation, risk readiness isn’t just protection – it’s performance.

Don’t wait for audits to expose risks – ERP for chemical compliance keeps you OSHA- and GHS-ready every day.