Running a business isn’t always easy, especially when there’s a lack of communication and no system in place to monitor data from your operations – problems all too common with legacy systems. The sooner businesses address these issues the better, and that means making sure whatever Enterprise Resource Planning (ERP) solution you choose can support your business now, and in the future. Having the right solution in place will be the best way to ensure you’re able to keep meeting your goals.

Across industries, modern Enterprise Resource Planning (ERP) implementations have become increasingly common. According to Deloitte, nearly 53% of IT executives say that effective Cloud ERP implementation is their top priority. A recent report from Allied Market Research expects the global ERP market to reach $117.09 billion by the end of 2030.

In this post, we touch on the importance of implementing a modern ERP – like Microsoft’s Dynamics 365 products – correctly and what they bring to the table.

Properly Implementing a Modern ERP

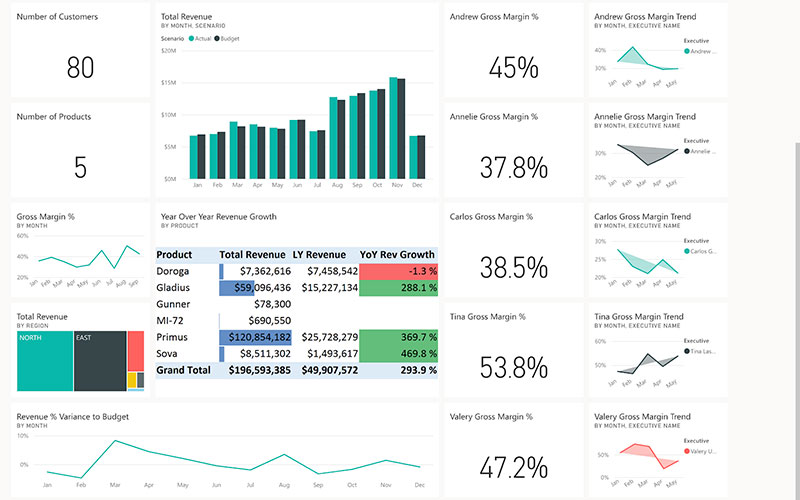

It’s true that modern ERP solutions like Microsoft’s Dynamics 365 Finance and Supply Chain Management open businesses to more possibilities. Microsoft’s ERP solutions offer Direct integration to Office products, enhanced collaboration, advanced analytics designed to generate actionable insights and boost efficiency, and more.

Often forgotten, though, is making sure you can implement a chosen solution properly – and this means collaborating with a Partner that understands the needs of your industry.

Figure 1:Benefits of Working with an ERP Implementation Partner

Important benefits of working with an ERP implementation partner include:

Fully streamlined and automated processes

With older systems, manual task allocation, tracking, and monitoring are becoming tougher and tougher as the system generates more data for every transaction. As workflows become more complex, organizations have to make significant investments to keep them up to date.

Microsoft’s D365 can automate and standardize even the most complicated workflows for efficiency.

Reduced cost

According to Deloitte, as much as 22% of operational cost savings happen with Microsoft ERP implementations. This has both a direct and indirect impact on overheads.

With powerful automation features, you can streamline how you schedule your resources. Microsoft’s D365 can easily automate tasks like task allocation, traceability, and report creation. This automation results in fewer errors and a reduced need for human intervention. This reduces organisations’ need to invest in third-party monitoring and optimization solutions.

Centralized data

Older, legacy solutions with siloed applications greatly hinder modern performance. This leads to excessive back and forth to access the correct data. This can be tough for any team, with the lack of instantly accessible data hampering performance and the ability to make quick decisions.

Advanced ERPs like Microsoft Dynamics 365 give users immediate access to critical data without additional effort or wasted time. All critical data is available from one platform where your teams can access whatever they need.

Performance monitoring and Real-time collaboration

Continuously finding and resolving issues is a crucial part of organizational growth. Microsoft’s D365 provides an extensive 360-degree view of tasks and workflows, allowing organizations to generate reports with actionable insights easily.

Teams that stay connected remain result driven. A proper ERP implementation means everyone in your organization will have access to performance data in interactive reports that users can share with other stakeholders. Users can share data, discuss goals, plan strategies, and work more efficiently with other departments.

Improved flexibility

D365 allows businesses to adapt to any changes in market demand quickly. This includes updating workflows as needed, allowing them to scale as your business grows.

This highly depends on your partner’s understanding of your industry and how your software is set up.

Best practices, reducing failures

A report from Deloitte revealed that nearly 55-75% of all ERP implementation efforts fail, citing poor system selection, incompetent data migration, and lack of implementation best practices – all related to your implementation partner.

To reduce the chance of failure and increase the possibility for success in any ERP implementation means following best practices:

Identify your ERP implementation objectives

Before starting any ERP implementation project, it’s important to have a good understanding of the following:

- Why do you need a new ERP? What is your proposed timeline?

- Will your new ERP need additional customizations?

- What functionality is critical to your business?

- What kind of downtime can you afford?

- What is the budget for your ERP implementation?

Selecting an ERP that aligns best with your goals

You wouldn’t wear dress shoes to a construction job, would you? The growing ERP market has different solutions, each with specific features. Make the wrong choice, and you could be stuck with that solution for years and years – this is where an experienced partner could guide you in the right direction.

For example, you may be leaning towards a lower-cost option, but is that solution scalable? Does it include access to everything you need, or will it require a significant customisation investment?

Microsoft has gone to lengths to ensure their Dynamics 365 ERP is a perfect fit for different enterprise types, combining CRM (Customer Relations Management), accounting, finances, marketing, planning, supply chain management, and more, unlike lesser ERPs.

Migrate data with utmost diligence

Lost, misplaced, or duplicated data is another major cause of failed ERP implementations. Even a single piece of critical data can lead to expensive fines, damage to a business’s reputation, or worse. This is why following best practices for migrating customer data is so important.

Data integrity should be at the top of the list in any ERP implementation.

Prioritize training

You may have worked with a certain ERP in the past, giving you a clear understanding of how it works – but not everyone has had the same experiences. This is precisely where Change Management comes in. Even if your chosen solution seems easy to use, your team must be comfortable with its capabilities. This means ensuring sufficient, ongoing training is part of the plan for any implementation.

If your users don’t receive the training necessary to complete their work in the new ERP system, you’ll never be able to achieve the results you’re after.

Final Thoughts

There’s a lot that goes into making sure your ERP implementation goes according to plan. Make the wrong choice, and your business will be stuck with inefficient or sub-par functionality that requires heavy customization or the added cost of third-party add-ons – an expensive decision.

The best way to ensure you make the best choice the first time around is teaming with a partner that’s been there before.

Experienced ERP partners will understand the best practices for your industry and which solutions make the most sense. They’ll work with you to optimize your ERP implementation according to your needs, giving you the best chance for success and long-term enjoyment of a scalable solution.

Schedule a Call today to see how we can help.