Introduction

Remaining competitive in today’s global marketplace has become more important than ever. Consumer habits continue to change, and businesses are finding themselves stocking more and more items. An efficient warehouse management solution is the best way to ensure customer satisfaction at a time when everyone expects things like next-day delivery, BOPIS (Buy Online Pickup in Store), and more.

Thankfully, managing a growing SKU count is getting easier and the technology already exists to help improve your supply chain and bottom line.

Keeping an eye on the changing technology landscape is a good way to get started – here are some of the advanced warehouse management trends we’ve seen in 2022.

Automation

More warehouses are striving to be fully automated than ever before, from self-driving forklifts and automated inventory systems to sophisticated barcode scanning and sorting. Many companies see full automation as a cost-saving measure as they shift their budgets from human workers to technology – becoming more important as SKU counts continue to grow to meet consumer demand.

According to Capterra, 54% of warehouses plan to expand the number of inventory SKUs carried over the next five years.

Manufacturing plants have seen similar trends, with equipment automation replacing traditional manufacturing processes such as machining and assembly. You’ll need to think creatively about how automation can change your processes and make your jobs easier. Some innovations include adding robotics or autonomous vehicles into your delivery process; building more efficient ways to collect data; or developing mobile apps that make data easily accessible to your employees, wherever they are.

Sustainable Warehouse Solutions

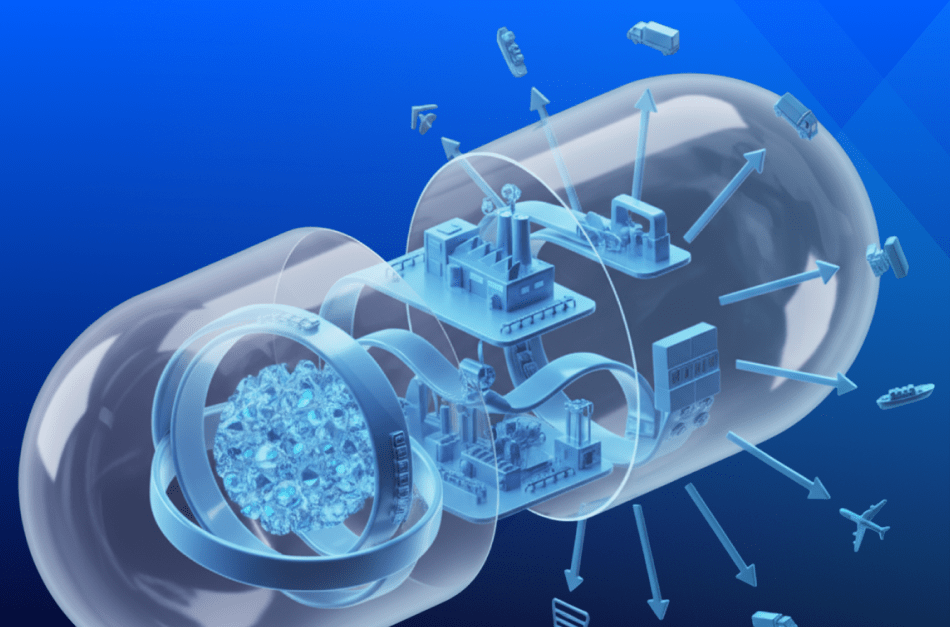

Supply chains and warehouses have always been a driving force of the economy, and as we move into the future, warehouse management trends will continue to affect global supply chains. One of the most significant changes driving growth in sustainable warehouse solutions is increased consumer pressure for sustainable goods and services. Consumers want more transparency and accountability with their products, which improved tracking technologies can only achieve.

Another factor influencing this change is an increase in regulations governing environmental impact. For example, several European countries banned single-use plastic packaging earlier this year due to the damage it causes, leaving companies scrambling for viable alternatives, like bio-based plastics or renewable materials like bamboo.

Supply chain management solutions like Microsoft’s Dynamics 365 will play a vital role in managing inventory, assets and faults and improving compliance with regulatory bodies like the FDA, EPA, REACH and more.

Internet of Things (IoT)

Internet of Things (IoT) technology in warehouse management continues to grow and offers new benefits like reduced costs, better forecasting, and easier scalability.

Sensors and cameras continue to improve, and newer RFID (radio frequency identification) tags or beacons tell you exactly where an item is at any given time.

The data collected from these sensors leads to a better customer experience because you know exactly how long it takes for a package to be delivered or whether there are any delays with your orders. This makes your warehouse inventory management easier.

When managing people, IoT technology will allow you to reduce overtime hours and increase efficiency. Using drones and autonomous vehicles lets you confidently adjust your business strategy by setting prices based on demand or supply chain availability.

Some experts predict that we’re nearing the point where IoT technology will be doing a lot more tedious work like stock picking and placing items into cartons—saving companies money and freeing up valuable labor hours for other things like customer service or development projects.

Wearable Technology

Technology is changing how work is done everywhere, and warehouse management is no exception. We already see hints that in the not-so-distant future, fewer people will work in warehouses due to the rise of wearable technology. Examples include Exo-suits, Smart Glasses and audio devices – powered devices designed to reduce physical requirements and give workers hands-free access to their data and instructions.

These devices could replace warehouse management equipment like head-up displays or tablets. Amazon, for example, has already patented a system allowing its employees to use wearable devices while at work. These devices focus on 100% accuracy thanks to the ability to fully validate your inventory.

Some analysts believe this trend would lead to higher costs for shipping companies and consumers because it would require new training programs, and many warehouses wouldn’t need human labor. Others feel these technologies might reduce costs because they increase productivity and reduce errors.

The fact remains that wearable technology holds exciting potential and could change the way we manage our warehousing processes. However, it’s still unclear exactly what effects it will have on business owners and consumers.

Augmented Reality (AR)

Even now, fulfillment centers are beginning to use augmented reality (AR) technology to help with logistics and planning. This trend is expected to grow and expand over the next few years.

There are many benefits, like training and easy visualization. Still, one of the most important is that warehouse managers and personnel can use AR daily without having an expensive changeover cost when they start using it.

This technology provides instant feedback with data from multiple locations, so managers know exactly if their supply chain is performing as expected or if any issues need to be addressed. The wireless nature of these devices means AR is perfectly suited for work in and around warehouses.

Digital Transformations

Warehouse management is going digital everywhere. E-commerce and omnichannel retailing have become much more popular, leading businesses to invest more in warehouse management software and automation. The ability to deliver products from their warehouse on time with less employee involvement is what many businesses have been aiming for.

Companies want their warehouses to be fast and flexible, moving with the needs of changing business conditions. Warehouses are now being designed with reconfigurable storage systems, which can be changed based on current storage needs without downtime or significant disruption.

For this level of automation and digitization to happen, these enterprises need a great deal of up-to-date data about their inventory and how quickly they can process orders. Fortunately, warehouse management solutions like Microsoft’s D365 provide real-time updates on inventory levels and shipping rates. These are just a few reasons we’re seeing more businesses finally replace their aging legacy systems – and when all is said and done, they’re much better off for it.

What comes next

Staying up to date on changes in technology can be a full-time job. One of the best ways to understand what comes next is by working with a partner that understands your business.

As your company grows and your warehousing needs change, your partner can ensure you’re using the perfect solution.

Whether you’re looking for a whole new warehouse management solution or just adding on newer functionality, your partner should be there to set you up for greater success.

Be prepared for what comes next, contact us today to find out how we can help.