Introduction

Full accountability and the ability to properly manage finances are essential to the success of any business. In today’s dynamic and constantly changing business environment, financial management has become increasingly complex, requiring firms to be agile, informed, and proactive in managing their finances.

To meet this need, more organizations look towards modern tools and technologies designed to help them streamline processes, optimize resources, and make informed decisions. Microsoft’s D365 is one solution that can transform how businesses manage their financial processes.

Microsoft’s Dynamics 365 for Finance is a comprehensive solution that helps companies manage their finances. From budgeting and forecasting to financial reporting, D365 allows businesses to make informed decisions, gain real-time visibility into financial performance, and optimize their resources.

In this article, we will explore the benefits of D365 for Finance, highlighting ways they help businesses achieve financial excellence.

A report by Gartner found that the adoption of financial management tools like budgeting and forecasting can reduce finance and accounting costs by up to 30%.

Budgeting

Budgeting is essential to financial management, enabling businesses to plan and allocate resources more effectively. With proper budgeting, organizations can accurately forecast revenue and expenses, identify potential cost savings opportunities, and make informed decisions on investments and resource allocation. Microsoft’s Dynamics 365 for Finance includes comprehensive budgeting tools that allow companies to create, manage, and monitor budgets in different departments and projects.

These highly customizable tools allow businesses to set up budgets at different levels, including company, department, and project. Businesses can create budgets based on historical data, forecast future revenues and expenses, and monitor performance against budget targets in real-time. Additionally, the tool enables businesses to allocate resources efficiently and effectively, ensuring each department and project receives the necessary funding to meet its objectives.

One of the key benefits of budgeting in D365 is real-time visibility into the financial performance that enables businesses to monitor their financial performance against budget targets and identify areas for improvement. With real-time visibility, businesses can make more informed decisions on resource allocation, cost control, and revenue optimization. This can help businesses optimize their financial performance and achieve their financial objectives.

Forecasting

Forecasting is a critical aspect of financial management that helps organizations predict future financial performance and plan accordingly. Without proper forecasting, businesses may miss opportunities or face financial risks that could have been avoided with accurate predictions. Microsoft’s D365 offers a powerful forecasting tool that leverages advanced analytics and ML (Machine learning) algorithms to provide accurate and actionable insights.

Forecasting in MSD365 is highly customizable, allowing businesses to model and simulate various scenarios based on historical data and assumptions. With the included tools, businesses can predict revenue, expenses, and cash flow, enabling them to make informed decisions on investments, resource allocation, and risk management.

Advanced analytics and machine learning algorithms enable businesses to identify trends, patterns, and anomalies in their financial data. This gives businesses the insights needed to make informed decisions, identify growth opportunities, and mitigate risks.

By leveraging the forecasting included in D365, businesses can proactively manage financial risks and opportunities. With accurate predictions, businesses can make informed decisions on investments, resource allocation, and risk management, ensuring they are well-positioned to achieve their financial objectives.

Financial Reporting

Financial reporting is the cornerstone of financial management, providing stakeholders a clear understanding of the organization’s financial health and performance. With accurate and timely financial reports, businesses can make informed decisions, identify areas for improvement, and communicate their financial performance to stakeholders. D365 provides a full suite of financial reporting tools that enable businesses to create and distribute reports quickly and easily.

These tools offer a variety of customizable templates, enabling businesses to produce reports tailored to specific audiences, such as investors, board members, or internal stakeholders. The tools also provide real-time data access, enabling businesses to create reports that reflect the most up-to-date financial information.

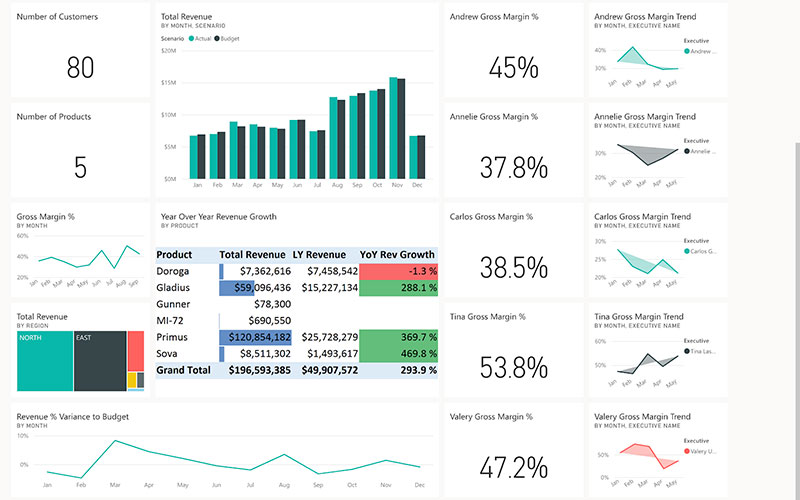

In addition to customization options, financial reporting in D365 offers intuitive visualization options, enabling businesses to present financial data in a way that is easy to understand and interpret. With features such as charts, graphs, and dashboards, businesses can quickly identify trends, patterns, and anomalies in their financial data.

Figure 1:Benefits of Dynamics 365 for Finance Management

Benefits of D365 for Financial Management

There are many benefits of using D365 for financial management, including:

- 1.Streamlined financial processes: D365 provides a centralized platform for managing financial operations, such as accounts receivable, accounts payable, and general ledger. By streamlining financial processes, businesses can reduce errors, save time, and increase productivity.

- 2.Real-time insights: With D365, businesses can gain real-time insights into their financial performance through interactive dashboards, reports, and analytics. This helps decision-makers to identify trends, make informed decisions, and take timely actions.

- 3.Flexible reporting: D365 offers flexible reporting capabilities, allowing businesses to create custom reports that meet their unique needs. Users can easily create financial statements, balance sheets, and other financial reports, all of which can be customized to reflect specific business requirements.

- 4.Integration with other systems: D365 seamlessly integrates with other Microsoft applications, such as Excel, Power BI, and SharePoint, as well as third-party systems. This enables businesses to consolidate data from multiple sources and streamline financial reporting.

- 5.Improved financial compliance: D365 is designed to help businesses comply with financial regulations, such as GAAP, IFRS, and SOX. The system includes features such as audit trails, transaction tracking, and role-based security, which help businesses to maintain compliance and reduce risk.

Final Thoughts

In conclusion, achieving financial excellence is crucial for businesses thriving in today’s competitive landscape. Microsoft Dynamics 365 (D365) is a powerful tool for finance management, offering businesses streamlined processes, real-time insights, flexible reporting, integration with other systems, and improved financial compliance. By leveraging D365’s capabilities, businesses can gain a competitive edge, reduce costs, and increase profitability.

Our organization specializes in helping businesses achieve financial excellence through customized D365 implementations and ongoing support. Our team team has extensive finance management experience and can help businesses leverage MSD365’s full potential to achieve their financial goals.

Together, we can take your financial management to the next level, streamline processes, improve insights, and achieve financial success.