At a Glance

- 18% – The hike in the Raw Material Price Index from 2020-2021 with at least another 10% hike expected.

- 60% – The increased amount of raw materials extracted, harvested and consumed since 1980.

- 117% – The increase in raw materials costs for non-food agricultural materials since 2000.

- 359% – The cost increase in rubber since 2000.

- 62 billion metric tons – The amount of raw materials used per year in 2008, an 8-fold increase since the early 1900s.

Introduction

Today, manufacturing relies heavily on the ability to acquire raw materials, both directly and indirectly. Examples of direct raw materials are the chemicals, textiles, minerals and other components that become finished products. Indirect raw materials are components added to other parts that together make a finished product. Accurate tracking of these materials is a good way to determine if a company flourishes or fails. Both of these material types are listed as current assets.

Tracking raw materials typically starts when they enter a warehouse. Their value is calculated from the start of a given time and adding costs such as storage, shipping, processing and labor to determine total value. Before you can build, mix or blend your products though, you have be sure to acquire them. Obtaining the essential materials you need to create your products is the end result of an involved process.

Obtaining Raw Materials

One of the first things to do before you start acquiring raw materials for your products is sufficient planning. Raw material planning can be used to determine how quickly you use each item, but only once you understand your inventory turnover rate – the number of times you use your raw materials.

In a previous post, we stated that “Materials planning is the method used to determine the requirements and quantities of raw materials to implement production.” If you don’t have enough raw materials on hand, you can add delays to your production schedule, or even lose orders altogether. If you keep too many materials on hand, there may not be enough budget available for other projects, like capital improvements.

A critical part of materials planning is understanding lead time: how far in advance do you need to place orders with your suppliers to get what you need in order to satisfy your customers?

Being sure you can order what you need requires a procurement management plan that, “defines requirements for a particular project and lays down the steps required to get into the final contract,” including raw materials.

This plan sets and defines everything you need to manufacture your products: what to buy, who to buy it from and how much you’ll pay. This includes determining purchase costs plus delivery and storage costs, also referred to as inventory costs. Placing an order, or receiving one from a customer, often uses an order management plan.

If your departments are unable to report how much of a given product, or the raw materials required in the process, are on hand, entire orders can be lost. When production tells sales one thing, but inventory says something else, the end result can be chaos. This is where accurate, frequent, communication that tracks the flow of raw materials through the entire acquisition process becomes critical.

Inventory Management

“Inventory management is important to small businesses because it helps them prevent stockouts, manage multiple locations and ensure accurate recordkeeping. An inventory solution makes these processes easier than trying to do them all manually.”

A chef can make a large salad using a full head of lettuce but only a teaspoon of spices. Managing inventory is often similar: A manufacturer is likely to have some items they use in large quantities, such as active pharmaceutical ingredients (APIs). Equally important are the catalysts and other chemicals bought in much smaller lots. Like a chef making a salad, without their ingredients, they don’t have a product.

Inventory management not only tracks what you have on hand, it also looks at your supply chain: making sure you have options for getting what you need when you need it. One part of inventory management is getting your basic supplies: making sure your customers receive their finished products when they need them is another. Having viable shipping options to ensure your merchandise arrives on time means gathering even more information and constantly updating your options. A common option used by a large number of companies, especially retailers, is vendor managed inventory.

Start tracking and managing raw materials efficiently, schedule a consultation with Xcelpros.

Vendor Managed Inventory

Commonly referred to as VMI, vendor managed inventory is when a company lets its suppliers determine the amount of product a company has in stock. If you walk into a grocery store you might see people who are not market employees stocking shelves. These are vendors – these employees track inventories, place orders, monitor shipments and stock shelves.

According to American Express, benefits of a VMI include:

Figure: 1Benefits of Vendor Management Inventory

- Improved efficiency You have the right quantities on hand to meet your needs without going overboard and having too much or too little.

- Cost reduction Having accurate inventories means few if any disruptions to sales, thereby providing better customer service.

- Reduced complexity Depending on your products, you may be able to reduce the number of vendors. The result is a predictable and reliable inventory schedule.

- Data insights Your supplier can anticipate demand, helping you prepare for seasonal and market-driven trends.

Working with a single VMI has some negatives as well as positives. Three of the biggest challenges, according to AmEx, include:

- Loss of control Someone else determines what products you have and therefore what you’re able to sell. Using a VMI also means an outside company has access to your private data. Data security can be a major issue, especially when you first start working with a vendor.

- Limited options It’s tough to make a fruit salad when the only fruit available is an orange. Your product choices may be limited and you might become dissatisfied if your vendor fails to deliver at the best price.

- Market agility Working with a single vendor reduces your ability to pivot when markets change. For example, some whiskey manufacturers were having problems selling their goods when the Covid-19 pandemic took hold. A few of the more enterprising companies were able to switch from making whiskey to producing alcohol-based hand sanitizer. Using a VMI might eliminate this flexibility to quickly change in response to market conditions.

Looking at your options and picking the best ones often comes down to software. Managing your raw materials and inventory accurately, especially when your company is growing and has distant suppliers, generates a lot of data. Managing this vast amount of data requires capable software.

Software Options

Depending on your needs, two types of software can help with your raw materials management, inventory management, order management, procurement management, stock management and resource planning needs:

- 1.Customized products designed to perform a specific function for a single industry with a company at a particular size. If your company is unlikely to grow, one or more of these products might be perfect for your needs. Using this type of software, you will likely need one product for each requirement. This is likely to mean using several different providers, potentially creating data exchange roadblocks. A second option offers greater flexibility, the option to handle many of these needs in a single package while also growing with you.

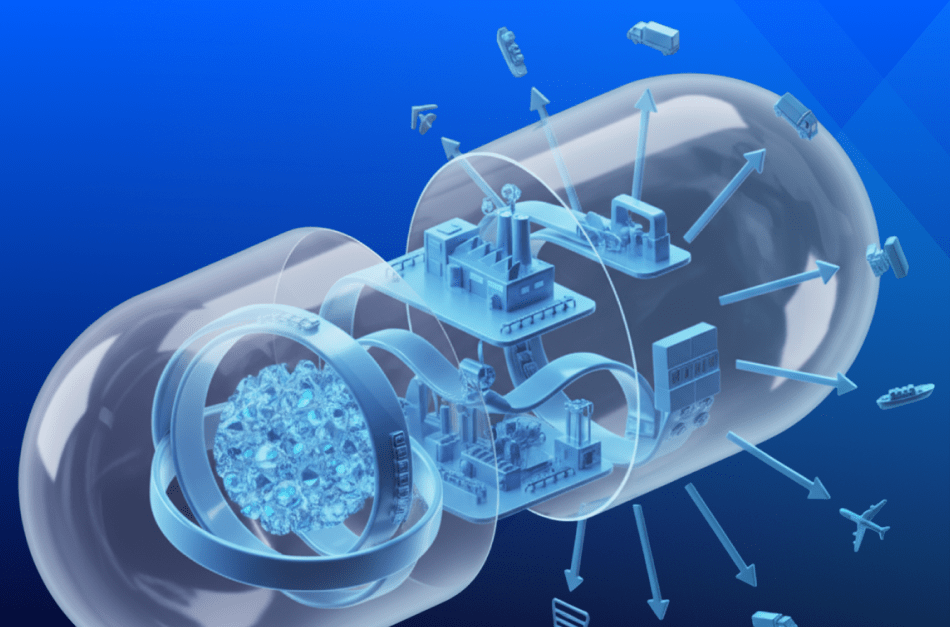

- 2. A modular Enterprise Resource Planning (ERP) product such as Microsoft Dynamics 365 Supply Chain Management is a large, versatile product capable of helping you track inventories from far-flung suppliers into, through and out of your warehouse. Microsoft Dynamics products are based in the cloud and offer added data security since they’re built on Microsoft’s Azure platform. Modular systems let you add sections when needed while maintaining constant communication between the modules. Using a system from the same company also ensures constant data flows, reducing inventory data errors.

The Bottom Line

Especially today, managing raw materials accurately requires a lot of work and attention to detail. Errors at any stage of the process – from ordering to shipping, storing or using – can result in expensive repercussions.

Finding the right software solution means evaluating your current and future inventory needs. What do you need now? Will solving today’s problem also work in 1-5 years or will it require an expensive overhaul?

The bottom line is that you should consider an investment in a modular product that can grow with your company over time, and not one that becomes obsolete the minute you expand.