At a Glance

- Chemical companies are more frequently moving towards fully adopting newer, digitized technologies and away from legacy systems and processes historically operated in silos.

- A well-functioning Enterprise Resource Planning (ERP) system helps chemical companies in all parts of their operations- procurement, manufacturing, supply chain, vendor management, aftermarket, and more.

- Implementing an ERP system doesn’t need to be costly or daunting, provided companies go for the right system and take the help of experts.

- The ongoing Covid-19 pandemic has highlighted the need for chemical companies, with the sector providing most of the raw materials used in sanitizers and personal hygiene products.

While digital transformations have been a big help for the advancement of every industry; many sectors are still looking for new ways to utilize these technologies to their fullest. The chemical industry is on the cusp of legacy and advanced software and systems. Many companies have departments working in silos, manual documentations, slow change management mechanisms, data discrepancy issues, and an overall fall behind when it comes to digitization and automation. Chemical companies can address these issues and many others by investing in a high-end ERP system.

According to PwC’s 23rd Global Annual Survey, 42% of chemical company CEOs prioritized and invested in digital operations and related technologies.

This statistic indicates that now’s the time for chemical companies to systematically restructure their IT base and look at ERP as an option and a way forward to sustainable growth. After all, every sector is looking to leverage digitization to their benefit, including the chemical industry.

Here are five benefits of an ERP software system for chemical companies:

1.Digitization of Processes Leading to Accelerated TimelinesAn intricately designed yet easy-to-implement ERP system such as the Microsoft Dynamics 365 ERP comes equipped with artificial intelligence (AI) and machine learning (ML) based features that can automate many processes such as documentation, reporting, log entries, etc. This will reduce manual intervention (providing personnel with time to invest in more innovative aspects) and mitigate errors. Digitization in the chemical industry also helps expedite processes as the data can be accessed, altered, and verified in real time. With Microsoft Dynamics ERP, chemical companies can realize the vision of going agile.

2.Fortifying Supply Chain Management (SCM) A comprehensive ERP for the chemical industry can facilitate better management of your supply chain by interlinking the departments and creating a data pool between finance, sales, and delivery. This way, you will digitize and monitor the procurement of raw goods, oversee warehouses, manage inventory more efficiently, channel communication between different stakeholders, and streamline the workflow.

Figure 1: A Multi Pronged ERP System to Integrate Different Departments in a Chemical Company

Start Your Digital Transformation Journey with Our Assessment.

3.Better Response Time and Quicker Time to MarketAn ERP for the chemical industry provides companies with a competitive advantage by giving better process and resource visibility, interconnecting departments, and avoiding bottlenecks. ERP also enables chemical companies to identify their slow-to-move inventories and find quicker delivery options. This considerably reduced time to market. The overall product development process in chemical manufacturing companies is also expedited, thanks to the automation and optimization features of ERP systems, and this also results in quicker time to market.

4.Dynamic Change ManagementThe chemical manufacturing processes are subject to changes at different levels, from pre-formulation to production and packaging. These changes take time to get recorded and notified in a legacy system-backed environment, leading to delays. With an ERP, chemical companies can be more flexible and dynamic in their change management approach. As data becomes centralized and systems become integrated, more collaboration can occur, expediting the communication network in a change management ecosystem. Even at the supply chain and aftermarket levels, ERP allows better visibility across several stakeholders, enabling manufacturers to respond quickly to any changes.

5.Better Customer Service and Enhanced Customer Satisfaction Like any other industry, the chemical industry strives to satisfy its customers- be it other industries, retailers, or end-users. With an ERP system for chemical manufacturing, companies gain insights into customer preferences and can anticipate market needs. Companies choose ERP systems designed to respond quicker and better to customer demands. With the ever-changing customer expectations scenario, chemical companies need to invest in a system that gives them better customer visibility and agility to respond.

ERP is a solution of possibilities, and chemical companies can turn these possibilities into opportunities. To survive, sustain, and thrive in this era of digitization, the chemical industry can use this software to integrate and collaborate better than ever before. It can also help to work with experienced consultants to maximize performance and reduce costs. While every company has different problems and requirements, well-designed chemical ERP software can efficiently address some issues.

Key Takeaways

- The chemical companies must analyze their as-is IT infrastructure and identify the right ERP system for their requirements.

- ERP is a dynamic, flexible software; thus, chemical companies can evaluate many aspects of their operations comprehensively with the help of a single system.

- With learned ERP experts, chemical companies can go places in terms of operating smoothly and delivering consistently.

Also Read: ERP Solutions to Rev Up Oil and Gas Industry

References: PwC’s 23rd Global Annual Survey

At a Glance

- 1.Poor software fit /inaccurate requirements

- 2.Business leadership is not committed to the implementation

- 3.Insufficient team resources

- 4.Lack of accountability to make timely, high quality decisions

- 5.Lack of investment in change management

- 6.Insufficient training/support

- 7.Insufficient funding

- 8.Insufficient data cleansing

- 9.Insistence on making ERP look like legacy

- 10.Lack of testing

Sources: ERPFocus.com

Introduction

Overall cost reduction, improved security, and interoperability are why small businesses invest in newer and agile enterprise resource planning (ERP) software.

The biggest question companies have at the start is: Do we use an on-premise solution or a cloud-based ERP?

On-premise solutions require more up-front costs for:

- Purchasing servers

- Creating databases

- The initial implementation

- Consultants

Ongoing costs involve:

- Information technology (IT) staffing

- On-line security

- Data back-up

- Duplicating this set-up for every site

Keeping everything local requires ongoing maintenance, specialized in-house or on-call consultants, upgrades, and updates. You’ll likely need more hardware as your company grows. As you add additional facilities, your computer infrastructure will also continue to grow.

Moving to the cloud can help reduce most of these costs by about 30 percent. Depending on the age of a company’s existing equipment, there may be some hardware costs in the form of upgrading existing equipment to ensure compatibility. These costs will pale compared to the expense of having to add or outright replace servers.

Among the features of a successful cloud-based ERP implementation are:

- The vendor is responsible for the cloud servers since it hosts and manages the software

- No additional IT costs for staffing, maintaining the hardware and software, software updates and upgrades

- The host (vendor) is responsible for your data security

This is just a small example of features and benefits of an ERP that pay off over time, especially when a company grows.

Other Cloud-Based ERP Advantages

Purchasing a cloud-based system has several other advantages beyond hardware and maintenance costs, including:

Scalability: A key reason growing companies move to the cloud is their ability to grow with it. Adding another 100 users might require expanding your server. As your company grows, adding new users to your ERP is just an internet connection away.

Agility: Does one part of your company require extra help with Supply Chain Management? An open-source-based ERP likely has a module designed just for that. Assuming you start with financial management, adding a sales component is a logical complement.

Disaster Recovery: Natural disasters such as fires, floods, or earthquakes are common everywhere. So are unnatural disasters in the form of riots and even wars. Cloud-based systems keep your data on multiple servers in different regions. When one server goes down, your data is safe on another. How safe are they? One ERP provider estimates that cloud systems are so secure and redundant its customers experience less than eight minutes of unplanned downtime a year.

Storage and access: This same geographical dispersal that means your data is safe from disasters also means that when you need more space, it’s easy to get. When your server farms occupy large warehouses, adding more terabytes—Western Digital has 18-20TB drives available for home computers with those in the 100TB territory made for commercial firms—is a power and data connection away.

Automatic updates: Cloud service providers provide around-the-clock monitoring. They are constantly finding ways to improve performance and data security. Microsoft, for example, employs 3,500 security engineers. They protect customer data in part by ensuring the Azure cloud computing platform is safe from all attackers.

Get started to learn more about key features and benefits of ERP systems

Plan Your Implementation

No matter what software your company has, and how robust your network may be, it’s still possible for your ERP implementation to fail. In fact, the average estimate of all ERP installations that fail is between 40% – 60%

Successful implementations often require focus on seven critical aspects.

Figure 1:Plan Your Implementation

- 1. It is choosing the right team. Your implementation team must have a good mix of talent. It should include people with experience in your particular business segment. Include business analysts, developers, software architects and project managers. The team must also include a strong-willed and senior management Champion from your company whose goal is ensuring the highest priority tasks are accomplished first.

- 2. We are planning a phased approach. Install the implementation in logical sections. This reduces disruption, especially when moving data from the old system to the new.

- 3. It was moving useful data only. Client data that is no longer relevant is not worth keeping. Bring over material that helps now and in the future. Reformat your data as it’s brought from the old system to the new while you perform the build. Separate that data into static, one-time entry data like customer lists, and dynamic information such as transactions.

- 4. It is setting achievable goals and expectations. A great way to accomplish long-term goals is by breaking each into a series of smaller steps, each with its payoff. Build on the previous step to accomplish the next and keep going.

- 5. Using the implementation to fine-tune your business. Many companies purchase an ERP system to reduce costs. Use the implementation to take a critical look at each business process. Where are the bottlenecks? Where is effort duplicated? How can each process be streamlined to be more efficient and effective?

- 6. Time is a sixth critical part of an effective ERP implementation. Don’t be in a hurry to turn the key; fire it up and race off. Successful implementations take six months to two years. Effective, thorough planning and a thoughtful, well-researched approach before purchasing will help ensure your ERP implementation is successful.

- 7. Another important task is understanding that a new ERP will look different from the old one. While having a familiar look and feel is nice, your staff will embrace an optimized newer version once they understand how well it performs. Microsoft’s Dynamics 365 line of products may look different than your old ERP, but it will retain some familiarity for Office 365 and Azure users.

Final Thoughts

Online ERPs are designed for flexibility and expansion. A cloud-based ERP is less expensive to maintain over time, no matter where your company has its production plant, warehouse, or office. Small businesses considering ways to improve efficiency and encourage growth will want to examine the many top ERP solutions available.

Before you buy, though, make sure you have:

- A plan with short-term, medium and long-range achievable goals

- An upper-level management champion

- A budget based on hard facts

- A willingness to change

- The strength and stubbornness to know that growth requires pain, the pain of change.

Taking the right approach will help your company prosper and grow.

Also read: Top 5 ERP System Trends in 2020 to help plan for 2021

Introduction

Modern pharmaceutical companies are undergoing a significant transformation with new opportunities from digitization, big data, and analytics. In response to COVID-19, businesses are seeing an increased need for an agile enterprise Business Intelligence (BI) architecture to leverage these opportunities in order to grow. Successful Pharmaceutical companies are looking beyond standard operational and statutory reports to implement more powerful Analytics and AI-driven solutions. These new solutions provide actionable insights and useful KPIs to help make better decisions. This leads to more empowered teams and new engagement that drives additional revenue.

Pharmaceutical companies generate massive information every day through their day to day operations. But the data is not always being put to the right use. Some companies tend to look at reports with a traditional eye that doesn’t drive a ‘call to action’ to grow the business.

The strength of any analytics software lies in its ability to help users easily create quick insights, especially for an agile business like pharmaceutical manufacturing. Creating reports in days instead of months frees up hundreds of hours in unnecessary spend to gather these hidden insights. This allows business leaders to repurpose cost savings towards other operational improvements and growth.

There is a right and wrong way of reporting – one provides overwhelming numbers, while the other means to understand those numbers and make them actionable.

As the pharmaceutical industry continues to undergo significant adjustments to new opportunities presented by digitization, big data, and analytics, more enterprises continue to see the need for an agile enterprise Business Intelligence (BI) architecture to leverage these opportunities & seamlessly deliver business-critical insights to executives.

The Strength of PowerBI

Power BI, Microsoft’s business analytics solution, lets you visualize your data and make it accessible to your Organization. Insights can be easily shared through various platforms of your Organization by embedding them in your app, portals, or website, collaborating on Teams, and integrating them into your ERP or CRM applications. Microsoft’s Power BI makes it easy to combine these numbers from different sources, streamline analytics onto a single dashboard, act on newfound insights, and enhance visibility to other teams in your organization.

Leveraging PowerBI interactive reports in a few quick and easy steps

- Onboard

- Access PowerBI either from powerbi.com or any of the Microsoft ERP/ CRM applications.

- Connect to your data wherever it lives.

- Explore your data with interactive visuals.

- Collaborate & Share

- Publish reports and dashboards.

- Collaborate with your team.

- Share insights inside and outside of your Organization.

- Access insights from anywhere

- Act with seamless access to data insights from your desk or home.

- Access on the go with Power BI visual reports built rapidly.

Book a demo to learn how Power BI can boost your pharmaceutical analytics.

Turning Industry Data into Smart Decisions

Leading Pharmaceutical companies who are transforming into agile organizations need 360-degree insights for business-critical functions such as manufacturing execution, sales productivity, financial management, purchasing raw materials from approved suppliers, quality assurance & quality control.

Today’s pharmaceutical organizations collaborate, monitor, and communicate on available live data to achieve operational excellence. Pharmaceutical business intelligence enables these organizations to monitor real-time data from multiple sources and combine them into one pharmaceutical dashboard with the ability to drill-down into the report to identify issues, as necessary.

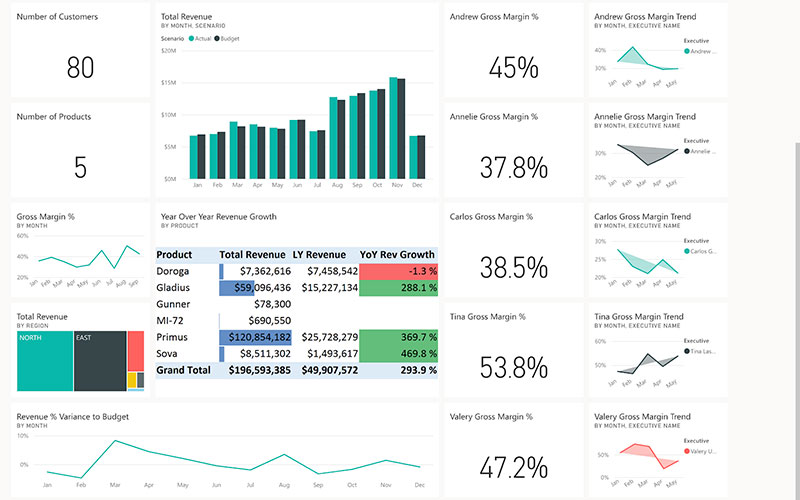

Figure 1: Pharmaceutical Analysis using Power BI

Usage in the Pharmaceutical Industry

01.Interactive Reports

Power BI is an analytics software that brings to the table a strong background in delivering end-to-end BI analytics to modern Pharmaceutical companies such as

- Efficiency Reports On Lot Production

- Trending And Analysis Of Quality Control Data

- Recommendations Based Clinical Trial Reporting

- And Financials Per Batch Produced For Each Product

- Product Go to market assessments (how much spend and types of activity is involved, expected and actual results)

02. KPI Reporting

Accurate decision making occurs when reporting provides clarity on both good and bad data points on prime KPIs. With business analytics in the pharmaceutical industry, companies can acquire intelligence in real time and can track key performance indicators like:

- Machine utilization

- Process efficiency

- Cost of Sales

- Inventory levels

- Batch Losses and cycle times

- Quality standards of a product line

- Customer engagement and customer experience

03.Real-Time Analytics

One of the essential requirements for agile Pharmaceutical companies is to have real-time analytics of overall operations, and to be able to make quick corrections and proactively handle situations before they turn into risks. Especially for manufacturing execution and pharmaceutical inventory management, knowing the work is progressing and inventory is turning around helps production supervisors to manage batch production processes much faster and make on the fly corrections. This real-time reporting on screens throughout a production plant gives needed visibility to both the managers and operators who can be alerted and fully aware of any issues.

Figure 2:Real-Time Data Tracking with Power BI

Benefits of PowerBI enabling business improvements

- 1. This information gives the ability to make changes to processes based on how well resources are functioning to increase productivity, and how each product lot produced is performing in the market.

- 2. Getting real-time alerts with Power BI mobile apps makes your operations more efficient, allowing you to achieve a higher level of organizational agility and minimize response times.

- 3. Power BI enables monitoring of your supply chain end-to-end, letting you identify problems and potential bottlenecks before they can affect critical processes.

- 4. Monitoring quality inputs and outputs from all sources, including your customers, allows you to make quick and meaningful decisions that will improve the quality of batches that are manufactured.

- 5. The ability to share your dashboards with suppliers and partners is a plus and accommodates adjustments to the latest information available to work towards making your processes leaner and smarter.

- 6. Microsoft’s Power BI is a full-featured BI solution that offers a number of benefits to many different organizations on their path to success such as –

-

- Global Scale – Local Speed

- Agile Business Processes

- Predictive Analytics

- Machine-to-Machine

- Employee Onboarding

Basic analytics used by the Pharmaceutical Industry

- Products & Inventory

- Full Track & Trace Functionality

- Enhanced Global Marketability

- Customer Requirements

- Product Quality

- Product Recalls

- Sales

- Quotes & Order analysis

- Pricing and Cost reporting

- Available-to-Promise reporting

- Order Profitability

- Supply Chain Management

- Match demand and supply

- Improved Supply Chain Responsiveness

- Updated and efficient Logistic analysis

- Financial

- Product Profitability reports

- Batch costs

- A full audit of transactions

- Manufacturing

- Safety and sustainability analysis

- Realtime production data reports

- Equipment failure predictions

- Production rescheduling

Final Thoughts

A big step towards change today comes from enhancing visibility across all operations including manufacturing execution, sales force productivity, procurement, and financials. Power BI brings to the table a strong background in end-to-end BI services for modern pharmaceutical companies – covering BI strategy, managed services, implementation & support, and even more. From the moment you start considering a BI solution for your growing Pharmaceutical company, the benefits of Microsoft’s Power BI become evident very quickly. Microsoft’s Power BI will continue to be a must-have product for leading Pharmaceutical companies by delivering a 360-degree insight of operations.

References: Advantages of Using Power Bi

Introduction to effective inventory management

Especially today, manufacturers, wholesalers and retail businesses from several different industries share several standard business practices, with inventory management at the top of the list.

An efficient, capable inventory management system can distinguish between struggle and success. Any boost to the efficiency of managing your inventory can result in a significant return on investment. To drive the effectiveness of your inventory management, especially when if you’re just getting started, it helps to pay attention to 10 popular techniques:

1.Fine-tune your forecasting Accurate forecasting is a must unless you want to either tie up precious capital in product stuck on warehouse shelves or be unable to meet your customers’ orders.

2.Identify low-turn stock Have a flexible ordering approach that, combined with accurate forecasting, lets to adjust inventory based on customer priorities.

3.Regularly audit your inventory Knowing—not guessing—what you have at any given moment lets you adjust ordering to ensure a balanced inventory.

4.Track stock levels You want to track all inventory from the moment you purchase raw materials or components to when you deliver finished goods to your customer’s door.

5.Keep track of your equipment Especially in a production plant – Knowing what you have, how quickly it wears and when to schedule repairs for optimal life ensures uninterrupted production runs.

6.Verify Quality Ensure all items in your inventory meet your quality control standards, ideally from the moment they arrive.

7.Categorize inventory based on customers needs Ensure you have the most sought-after products in stock at all times, working your way down the line to the least popular products.

8.Consider drop shipping This is much quicker especially for any items you don’t make yourself, especially when it becomes part of your product. An example is a Siemens ® controller for industrial machinery.

9.Rotate your stockTurn your stock so the oldest items are sold first This is especially true for pharmaceutical products with comparatively short shelf lives.

10. Use good inventory management software A viable program that meshes with your financial and sales software helps keep everyone informed, making for happier customers.

Get a consultation on how to track and control inventory in the warehouse.

Figure 1:Common inventory management challenges

Common Inventory Management Challenges

Among the most common inventory management challenges that can affect a number of different businesses are the following:

- Inconsistent tracking Working with older software that relies on manual data entry opens a company to data entry errors. Mistakes are bound to happen when different departments use different spreadsheets to input the same information.

- Inaccurate data Companies need to know how much of everything they have on hand and in the pipeline. Without accurate information, you won’t be able to track your production. This can be a massive problem if you’re still manually entering data.

- Order management Manufacturers often live on the edge of logistics, struggling to make sure deliveries are going out just in time – right before their customers need them.

- Juggling a complex supply chain Manufacturers need alternate ways of obtaining raw materials and shipping finished products. For example, your primary port is running behind because dock workers are sick. How do you get what you need when you need it?

- Communications and planning Intercompany communication is critical, especially in a world where companies often have business units in different countries, keeping everyone focused on the same task can be difficult.

- Robust competition In every industry, competition is ready and willing to grab your customers when you make a mistake or find yourself unable to deliver on time and within budget.

These are a few examples of the challenges faced by modern manufacturers. Thankfully, the good news is that modern ERP solutions can be a huge help when it comes to addressing these issues.

Inventory Management Software As a Solution

Several inventory managements programs available on the market today that focus not only on addressing these challenges, but also by identifying potential issues before they can impact your operations. Some of the best solutions available, like Microsoft Dynamics 365 Supply Chain Management, can seamlessly integrate with your existing software, reducing data silos, allowing different departments to share more information. Instead of requiring three departments to input the same information into a database, each group is able to provide material unique to their specialty.

Effective inventory management programs like Microsoft can print barcodes and QR labels. When these codes are scanned with a hand-held reader or cellphone, users can be rewarded with a wealth of information. The most critical data to track are precisely how much of any product you have, where it’s being stored, and what it will be used for.

For example, you need to produce 20,000 doses of a Covid-19 treatment. Your customer needs them yesterday but will settle for next week. Do you have enough raw materials on hand to meet your customer’s deadline? If not, what can you do to obtain what you need?

Using this information wisely lets management develop complex plans, like the ability to track everything from small lots to pallet loads. A company can learn by checking an item’s progress at different points—its arrival at the warehouse, use in production, loading onto a truck or ship, and delivery to the customer. By examining reports, you can identify potential delays or roadblocks and find ways to speed up delivery.

Supply chain management software on a secure cloud computing platform like Microsoft’s Azure let’s you communicate securely and safely with other researchers, salespeople and vendors. With Azure, you’ll know that your intellectual property and contracts are safe from competitors.

Boost Decision Accuracy with Power BI

With today’s supply chains – seemingly constantly in a state of upheaval – effective inventory management that goes beyond tracking stock on hand is critical to operations. Effectively managing your inventory and raw materials ensures you’ll have the materials you need when you need them. It means having more than one source of supplies and materials. It also means constantly checking with vendors to ensure you have the goods to meet your own delivery deadlines. This is where an integrated business intelligence solution comes into play.

Microsoft Power BI let’s you connect to hundreds of data sources, preparing reports you can easily share. You can confidently deliver interactive messages to customers using information from inside and outside your company. Inventory planners can be warned of potential shortages in time to find alternate supplies. Salespeople can be told of possible delivery delays caused by outside forces, giving them time to ask the customer if they want to use a different shipping method.

Accurate business intelligence at your fingertips puts you ahead of competitors stuck using their “tried and true” methods that are becoming increasingly worthless every day.

Final Thoughts

Effective inventory management comes down to data: knowing what you have and where it is.

A modern inventory control system that supports labels and barcodes lets you track raw materials, work-in-progress and finished goods simultaneously, with high accuracy.

An inventory system with business intelligence helps you find faster and alternate ways of obtaining raw materials and pre-made products, mainly when shipping delays occur. That information can help you get your products to your customers when needed, balancing everyone’s inventory.

At a Glance

- Disruptions brought by Industry 4.0 and digitization in the pharmaceutical sector are undeniable. Thus, pharma companies must arm themselves with state-of-the-art software solutions and tools to stay ahead in the game.

- Tracking, tracing, and serialization need the support of automated tools that can reduce manual efforts and mitigate the errors leading to stock-outs, delivery issues, and callbacks.

- Pharma companies need to be sure they comply at all times. An ERP with Pharmaceutical and Biotech centric solutions help companies meet all the regulatory requirements.

Technology has taken over our way of life and way of work. All major and minor sectors are undergoing massive changes to adapt to these changing times; the same goes for the pharmaceutical industry. Pharma companies worldwide face various challenges, such as increasing process complexities, changing consumer dynamics, healthcare reforms, a growing abundance of data without the infrastructure to leverage it, and more. These changing tides caused pharma companies to look at ERP as a panacea to solidify their IT framework and use the latest technologies (Cloud, Big Data, Automation, Artificial Intelligence, Machine Learning, Data Analytics, etc.).

However, merely adapting an ERP system will not give pharma companies value for their money.

In fact, according to a report by Gartner, by 2021, ERP cloud enterprise application implementation labor rates will increase by 60 percent due to high demand and a lack of skilled resources.

This realization indicates that, like other sectors, the pharma industry would need to invest in skill upgrading of their employees and get expert ERP consultants on board for a smooth implementation.

Now, let’s talk about the need for an ERP software system in the pharmaceutical industry in today’s time (especially as it needs an ERP that is tailor-made for the industry’s regulations and norms). Below are some of the key reasons for pharma companies to move to ERP

Manufacturing formulation and preformulation management

The drug manufacturing process comprises strict formulation and monitoring raw material ingredients and finished product yields to produce a batch. The pre-formulation stage includes defining drug production procedures, steps, quantities, etc. With a robust ERP system, such as the Microsoft Dynamics 365 ERP, pharma companies can ensure automated management of these formulations without constantly monitoring productions and worrying about manual errors.

Effective product costing

The costing of drugs involves various factors such as raw material master management, procurement cost, supply chain tracking, vendor cost management, and so forth. In a legacy system, these departments work in silos, and changes in data or any variable take time to communicate to other branches. There’s centralized access to data with an ERP system, and an interconnected network is established between various functions to develop concurrency. Well-captured data helps in efficiently defining product costs, and any changes can reflect in the system, enabling finance to accommodate those changes appropriately.

Figure 1:Benefits of ERP for Pharmaceutical Companies

Get a Consultation to Begin With Digital Transformation and the Role of ERP Systems in the Pharmaceutical Industry.

Meeting Regulatory Compliance

Regulatory compliance is a big one for all pharma companies. These regulations affect the brand name and consumer’s trust, but there is a factor of safety involved. Regulations and norms also differ regionally. It is essential to stay on top of safety and healthcare protocols to maintain global standards, and this is where a comprehensive system like Microsoft Dynamics 365 ERP can serve as a game-changer. Its flexible interface, centralized networking features, and automation solutions allow pharma companies to keep up with the changing rules and regulations and helps drug manufacturers to track these measures and stay compliant.

Pharmaceutical companies are also mandated to maintain CFR 21 Part 11 where it’s a statutory requirement to record (or document- either in print form or electronically) the steps and procedures that comprise complies with this FDA-regulated electronic signature and the production of a medicinal product. Microsoft Dynamics 365 Finance and Operations is compliant with this FDA-regulated electronic signature and electronic record.

Systematic and Efficient Inventory Management with Real-time Tracking

Effective inventory management for a smooth supply chain and avoiding stock-outs or bottlenecks are always concerns for pharmaceutical companies. This concern has reached the global level as governments worldwide are looking to manufacture or procure enough potential Covid vaccines and manage inventories so that the doses go to their population smoothly. An ERP system can help with a real-time track, trace, and serialization to manage inventory and avoid plausible glitches. An ERP system can also help accelerate product recall with its high-end traceability solutions.

Managing Variability and Predicting Scalability

Manufacturing of drugs involves managing supply chain variability, understanding its sources, and gaining a hand over release failures. Another aspect is predicting the scalability of product demand to alter manufacturing capabilities/capacities effectively. Both these involve strong communication between different functions and the use of data to preempt change. With a robust ERP for the pharmaceutical industry, companies can achieve these goals through predictive analysis, data crunching, and supply chain visibility.

Final Thoughts

Pharmaceutical companies can benefit a great deal from an effective ERP implementation. This transition leads not just to accelerated production but is a massive plus in streamlining operations and managing costs.

- A cost-effective and flexible ERP system such as Microsoft Dynamics 365 Finance and Operations enables pharmaceutical companies to take the proper steps in digitization, automation, and artificial intelligence.

- ERP system is the need of the hour, and getting expert consultants on board can help pharma companies meet their customized financial, operational, and regulatory requirements.

- Industrial dynamics are changing at lightning speed, and the pharmaceutical industry needs to keep up with these changes to stand the test of time.

At a Glance

- $985 million: The median cost of getting a new drug into the market

- $1.3 billion: The newer, lower average cost of getting a new drug to market

- $2.8 billion: The previous average cost of getting a new drug to market

- $200 billion: The estimated size of the counterfeit drug market

- 13: the number of new drugs not brought to market each year because of revenue losses from counterfeit drugs

Sources: Wikipedia and Statista.com

Introduction

On average, the cost of bringing a new medicine from idea to market – aka the drug development process – has dropped significantly, from $2.8 billion per drug to $1.3 billion each, according to an online encyclopedia. Counterfeits still have a measurable effect on the number of drugs being brought to market. Recent studies published on Wikipedia and Statista.com show that prescription drug makers continue to get hammered by counterfeit competition.

Statista’s 2022 study provided interesting data on different scenarios showing changes based on market size. The number of new medicines not brought to market ranged from six at $100 billion to 28 at $431 billion

So, what does all this mean? The short version is big pharma and even smaller companies have a considerable investment in intellectual property (IP) they must protect.

IP and Drug Manufacturers

“IP rights, if sufficiently limited, are typically justified as necessary to allow pharmaceutical manufacturers the ability to recoup substantial costs in research and development, including clinical trials and other tests necessary to obtain regulatory approval from the Food and Drug Administration (FDA),” the Congressional Research Service states (CRS).

Pharmaceutical companies are protected by two types of intellectual property (IP): patents, which give exclusive rights to the holder for 20 years, and regulatory exclusivities. According to CRS, these exclusivities range from six months to 12 years, depending on the specific type of drug or biologic.

These companies have a substantial financial investment in their research, development, and testing data. The only way to recover their vast assets is by making and selling products.

It can cost millions of dollars and over ten years of dedication to developing a single drug. With the money levels involved, thieves have a solid incentive to capture this research for themselves.

Protecting Your IP Investment

Take a look at another statistic: $590 million. That’s the amount the U.S. Treasury Department estimates was paid by victims of 450 ransomware attacks in the first half of 2021 alone.

Using that short time frame alone, the Treasury’s Financial Crimes Enforcement Network (FinCEN) stated that “ransomware is an increasing threat to the U.S. financial sector, businesses, and the public.”

Ransomware is one of many cyber-attacks that share a common goal: stealing money. This attack works by infiltrating a company’s computer network and taking control of it. Companies face a difficult decision: pay the ransom, have their data destroyed, or worse, share it worldwide.

Distributed denial of service (DDoS) attacks is another standard weapon in a hacker’s arsenal. “In computing, a denial-of-service attack is a cyber-attack in which the perpetrator seeks to make a machine or network resource unavailable to its intended users by temporarily or indefinitely disrupting services of a host connected to a network,” a Wikipedia article states.

Many of these attacks start with simple phishing schemes. If they get one employee out of thousands to open an infected email, they have a doorway into your data. Microsoft does everything it can to block these attacks and protect its investment and yours.

As with ransomware and other attacks through stealth or brute force, the goal of DDoS attacks is money. The thinking is, “Hit a company badly often enough, and it will pay you to leave them alone.

Figure 1:Key Strategies to avoid cyber security attacks

Book a consultation to discover more about Azure protection in the pharma industry.

Protection in the Cloud

Every company has another option, though: investing in its security.

One method of stealing data involves capturing it as it moves from place to place. Microsoft has invested millions of dollars to continuously protect its customers’ data through its Azure cloud computing platform. The company stated in a recent blog post that they detect 1.5 million attempts per day to compromise its systems, spending about $1 billion a year on computer infrastructure security.

With the ongoing need to invest in protecting their on-premise equipment from attacks, more firms are migrating to the cloud, with platforms like Azure gaining importance with each thwarted attack. Moving data from on-premise network servers to widely spread cloud data centers means attackers have to hit moving targets if they want to control a company’s data.

“The cloud has some built-in advantages. Unlike the internet, it was built from the ground up with modern security and privacy in mind. It’s also a controlled ecosystem protected by people who spend all day thinking about data security and privacy,” according to a recent Microsoft online store.

Traditionally, internet and computer security safeguards were bolted onto a tool rather than built into it. “With cloud infrastructure, security considerations are part of the development process,” Microsoft states. “The cloud is an opportunity to do security better,” security analyst Doug Cahill added.

Azure’s status as a cloud platform means that all of the money, and the 3,500 security engineers Microsoft devotes to making it secure, also benefit the software running on top of it. For example, Microsoft Dynamics 365’s Supply Chain Management, which helps companies track raw materials and finished products from the warehouse to the customer, runs on top of Azure.

Companies using this software get the bonus of automatic protection for their cloud data. While these updates can’t directly help prevent thieves from making a physical attack on their buildings, it can make it harder for them to steal data on the move.

“If we detect a set of attacks on one tenant or a handful of tenants, we can synthesize that and start using the things we learn to protect all the other tenants out there,” Bharat Shah, Microsoft’s vice-president of Security for Azure platform, said. “That’s the cloud effect. We learn. We react. We turn something on, and we protect everybody else.”

Azure benefits from Microsoft’s investment in machine learning – a branch of artificial intelligence – to track attempted attacks. Microsoft takes what it learns and uses it to benefit not just Azure but all the companies who’s multi-million-dollar intellectual property investment rides on top of it.

The Bottom Line

Citing the NETSCOUT Threat Intelligence report, Forbes.com estimated 26,000 cyber-attacks per day, or 18 per minute, in 2020 alone. The report indicated that security threats against industrial control systems and operational technology tripled in 2020, while DDoS attacks will grow to 15.4 million by 2023.

These numbers should make any executive who doesn’t have a significant cyber security team on their staff nervous. Thankfully, companies who use Microsoft Azure’s cloud computing platform have the security of more than 3,500 security engineers devoted to protecting it and the data running through it.

With the livelihood of pharmaceutical companies depending on keeping their data safe, secure, and private, you don’t risk your company’s data with poor security. Investing in Azure services today can make a huge difference in your bottom line.

At a Glance

- The manufacturing industry operates best by integrating people, tools, processes, and information.

- The data generated from each of these facets needs to be quantified and analyzed.

- In the manufacturing world, organizations that know their metrics tend to understand the tricks of the game.

- It’s critical to focus on the metrics that matter the most; the ones that help your entire organization gain essential insights regarding different functionalities and business areas to continuously improve the manufacturing process.

- One key that comes from knowing and managing your manufacturing metrics is the ability to systematically optimize your operations based on results.

In any industry, it’s essential to know exactly what your numbers are and what they mean to your business. While this sounds like it should be simple enough, we all know how difficult this can be in practice. When you’re able to gather numbers and metrics they still need to be collated, classified, quantified, and analyzed to add value to the business, especially for a multi-pronged industry like manufacturing. Manufacturing metrics can be diverse, and each metric has a different value throughout the manufacturing value chain. A cumulative study of a group of these metrics is a good way for manufacturing companies to gauge their performance and form strategies for continuous improvements.

Figure 1:Cycle of Continuous Improvement Methodology

As a manufacturing company, you always want to aim for a higher ROI which can mean a thorough analysis of manufacturing metrics and alignment of short-term and long-term business goals. Each of these metrics serves as a source of truth, representing a precise measurement of your manufacturing processes either in terms of quality or quantity (and sometimes, both). Let’s take a look at the manufacturing metrics that matter the most and how you can fortify your IT infrastructure to study and derive insights from these metrics.

1.Demand Forecasting Market research helps companies gain ideas to make estimates about demand forecasting. A manufacturer’s objective is to gauge the amount and type of raw material they will need for their upcoming business cycle. Planning, supply chain management, and operational alignment can benefit significantly from this metric’s help. It’s essential to remember that demand foreshadowing is dependent on external factors and, as such, subject to sudden changes. Take, for example, the ongoing Covid-19 pandemic. Many manufacturers found that much of their yearly estimates had taken a hit (especially sectors like automotive and luxury consumer goods). On the other hand, the demand for things like medical equipment and hygiene products increased by several fold, the world over. In this scenario, manufacturing companies can benefit from a robust enterprise resource planning system such as the Microsoft Dynamics 365 Finance and Operations that seamlessly enables change management, demand analysis, and order management.

2.Throughput & Yield of Units Produced A manufacturing company’s operational efficiency is directly proportional to its yield. Throughput is a metric that measures the average number of units produced in a particular amount of time (other coefficients being per machine, per production line, or facility). Access to the correct yield information helps manufacturers gauge their performances accurately, address bottlenecks, and develop plans for improvements.

63%

of manufacturing executives plan to get more out of what they already have invested within their manufacturing and supply chain network.

Source: Accenture

3.Inventory Turnover Properly managed inventory is a strong indicator of a manufacturing companies’ performance- after all, knowing how often inventory is sold or used in a particular timeframe is the measure of knowing its success in the market. This is precisely why decision-makers in the manufacturing industry focus on analyzing the turnover data of their inventories. To expedite the analysis and avoid data mismanagement, manufacturers still using legacy systems need to strongly consider investing in an automated ERP system that can track inventory data in real-time and facilitate seamless coordination between multiple stakeholders.

4.Quality Analysis The final quality of your product is one of the best indicators of production performance. A successful product is the best way to build your customer base, making it essential to understand applicable quality metrics- including monitoring and documenting raw material quality, incoming supplier quality, random quality checks at manufacturing plants, packaging quality, and more.

5.Overall Equipment Effectiveness (OEE) Whether it’s a single piece of equipment or an entire production line, knowing how effective every piece of equipment is, has become essential to a timely yield that matches quality and quantity requirements. This metric is recognized by the manufacturing industry worldwide as one the most important to assess agility, downtime, and overall production quality.

Book a demo today to learn how Microsoft Dynamics 365 helps you achieve manufacturing KPIs.

The metrics above are just a few in manufacturing that often generate mountains of data through multiple sources that are constantly subject to changes. The answer to managing all this information is a data pool – a single source of truth for multiple manufacturing metrics that can help companies track, manage, and analyze the data against their KPIs.

Figure 2:Role of Sophisticated ERP in Managing Manufacturing

Implementing Microsoft Dynamics 365 ERP and Power BI lets you optimize your IT infrastructure to systematically allow real-time data access, multi-level visibility, and artificial intelligence-backed insight generation. This allows you to visualize and track the progress of your manufacturing metrics, along with a cumulative awareness of your production line.

Final Thoughts

For every manufacturing company operating today, metrics and KPIs have become among some of the most important things to understand and track. How you view these metrics moving forward, how accurate the information is, and how you’re able to leverage it will be the deciding factor in your success.

- Every company needs to reinvent its best practices with the help of manufacturing metrics for a profitable business.

- Investing in a fortified IT infrastructure to track and manage manufacturing metrics is the need of the hour for manufacturing companies.

Introduction

Members of your U.S. sales team schedule an online meeting with their European counterparts, the video and audio conferencing is run through Microsoft Teams. All of your employees, from the chairman of the board to the people in the mailroom, have an email account they access through Microsoft Outlook. Your accounting department ensures everything it does is backed up on the cloud using Microsoft OneDrive. Nearly everyone in the office uses Microsoft Office 365 for everything from writing memos to generating invoices and keeping track of inventory.

What do all of these actions involving distributed computing have in common? Teams, Outlook and OneDrive and the corporate versions of Office are just a few of Microsoft’s many office programs that run on top of Microsoft Azure.

“Azure is the cloud platform that underpins all of Microsoft’s cloud services, including Microsoft Teams. Our workloads run in Azure virtual machines (VMs), with our older services being deployed through Azure Cloud Services and our newer ones on Azure Service Fabric,” ZDNet quoted Microsoft as reporting on its own blog in early 2021.

Whether you know it or not, the odds are your small to medium-sized business is using Azure, even if you have no idea what it does.

What is Microsoft Azure?

“The Azure cloud platform is more than 200 products and cloud services designed to help you bring new solutions to life—to solve today’s challenges and create the future. Build, run and manage applications across multiple clouds, on-premises and at the edge with the tools and frameworks of your choice,” according to Microsoft.

Azure is the foundational program Microsoft uses for all of its cloud computing offerings. To put Azure in perspective, consider a table. It has four legs and a top. You could not put anything on the table without the four legs, which are the core hardware components of computer processor, memory, motherboard and power supply. Just having four legs alone would be worthless without a top, which in this case is Azure’s function: it serves as the underpinning of your other programs. The tools you use, like Microsoft Dynamics 365, Teams and Microsoft Office don’t run in a vacuum: they’re all supported by Azure.

Azure provides three primary services:

- Software as a service (SaaS), which is subscription based

- Platform as a Service (PaaS), which lets customers run, develop and manage applications

- Infrastructure as a Service (IaaS), which are online services

Considered a hybrid cloud product, “Azure is the only consistent hybrid cloud, delivers unparalleled developer productivity, provides comprehensive, multi-layer security, including the largest compliance coverage of any cloud provider,” while also being less expensive than Amazon Web Services, Microsoft states. AWS is Azure’s main cloud computing competitor.

One report showed 234,731 companies using Azure from 2015 to July 11, 2018. It was ranked third out of 81 competing cloud platform and service products used by nearly 2 million companies. Two offerings from Amazon lead the list. Products from Google and Rackspace complete the top five.

What Is Azure’s Best Feature?

The reason why 95 percent of Fortune 500 companies rely on Microsoft Azure is security.

“Everything sent within the Azure environment is automatically encrypted. The Azure network has automatic detection to prevent distributed denial-of-service (DDoS) attacks, similar to some of the largest services on the Internet, such as Xbox and Microsoft’s Office 365,” Cloud Business states.

Figure: 1Organizations compromised by cyber attacks

In fact, according to Cloud Business; Microsoft invests $1 billion every year into security, which includes protecting Azure. In terms of security features that Azure uses to protect Microsoft’s many clients, including:

- Automatic encryption, hiding everything that goes through it from prying eyes.

- Automatic smart traffic monitoring and profiling that detect and deflect threats that look out of the ordinary. This approach helps reduce risks caused security threats that broke through external systems.

- Smart access control, which routes management (i.e., administrator) accounts over separate networks from most employees. Azure lets managers control and restrict down to the individual document level, further protecting your secrets.

- Regular hardware and firmware code revisions, which helps protect against threats before software is loaded and active.

- Providing access to Azure through an encrypted virtual private network (VPN) regardless of where a customer is located. People in Milwaukee and Mumbai access Azure through a VPN.

- Special computing environments known as Trusted Execution Environments or TEEs, which ensure that no matter where encrypted is—stored, in transit or inactive—is safe.

Microsoft also has 3,500+ cyber security experts on staff. Of that, 200 focus on finding weaknesses in Azure. The resulting information then becomes part of Azure’s operational security procedures.

Book a Azure demo and secure your data from cyber assaults.

Is Azure’s Infrastructure Secure?

If Microsoft trusts Azure’s security, your company should, also. In a series of four blog posts by Azure Security’s Director of Program Management, Avi Ben-Menahem, he provides three reasons why Azure’s infrastructure can securely keep their customer’s data safe.

- 1.A secure network infrastructure. “Management (Microsoft-managed) networks and customer networks are isolated in Azure to improve performance and ensure the traffic moving through the platform is secure,” Ben-Menahem wrote. The system is designed to help keep unauthorized people off a customer’s network. Microsoft manages an essential part of network cabling, the equipment to support and secure the network, and the integration of systems used to monitor the network.

- 2.Integrated security controls in Azure’s hardware and firmware. This ensures Azure is secure by default throughout its lifetime. Hardware security is enhanced by Project Cerberus, which is a chip containing a CPU, memory and programmable input/out that protects against unauthorized access and malicious updates.

- 3.Regular competition between Red an Blue teams of cybersecurity experts. Red team members try to compromise Azure’s infrastructure while the Blue team attempts to stop it. “At the end of each red and blue team exercise, the overall team codifies what they’ve learned into the Azure operational security process, so the team becomes more effective at continuous detection and response,” Ben-Menahem explained.

“Microsoft’s scale of investments across infrastructure, hardware and experts are unparalleled. Microsoft provides a secure infrastructure for our datacenters, composed of segregated networks, well-maintained hardware and firmware, and industry-leading operational security processes so that you can have more resources available to deliver business value,” he concluded.

Data is seamlessly altered into a stream of meaningless numbers when encrypted and then decoded into everything from words and numbers to videos, all without human interaction.

Final Thoughts

Today, businesses of any size need to give serious thought to adopting Azure as their cloud computing platform of choice if they haven’t already.

Azure’s focus on security means you don’t have to worry that some external group is going to use a distributed denial of service (DDoS) attack to damage or steal your intellectual property.

Constant, ongoing efforts by over 3,000 cyber security professionals as well as Microsoft’s ongoing effort to improve their products means your data is safe, not just today, but well into the future.

At a Glance

- Worldwide pharmaceutical companies are dealing with drug counterfeiting, adulterations, supply chain thefts and packaging glitches.

- Serialization is much more than just applying barcodes to personalized medicines.

- This modern age of fast-paced digitization calls for modifications and improvements in serialization techniques.

- To better strengthen the supply chain, loopholes need to be identified and closed.

- Transparency needs to be maintained for every drug dose.

- Pharmaceutical companies and their supply chain vendors should use of advanced analytics, cloud computing and the Internet of Things (IoT) to get a grip on modern serialization techniques.

Introduction

Traceability in pharmaceuticals is now very much seen as a global mandate. With laws differing from country to country, major pharmaceutical companies are looking for ways to improve how they track and trace their products in the supply chain to always remain in compliance.

Struggling to meet those requirements continuously is causing pharmaceutical companies to develop and implement new serialization techniques. Supply chain security, battling counterfeit and altered drugs, better product traceability, and overall cost-savings are chief among the motivations.

Reports suggest that by 2023, more than 90% of the global drug supply will be scrutinized under track and trace regulations. The program will enhance patient safety measures by combating drug counterfeiting.

Serialization is no longer restricted to global compliance mandates either. It’s helping more and more pharmaceutical companies add transparency, accountability and integrity to their supply chains.

Serialization is proving to be more effective at reducing shrinkage (i.e., errors and theft) than other solutions such as sturdy packaging and traceable 3D hologram models.

Figure: 1Common Loopholes in the Pharmaceutical Supply Chain

Innovation is the key to improving trace and track in any supply chain model, including the frequently complex pharmaceutical supply chain.

Companies worldwide are investing millions of dollars in maintaining product integrity.

Assigning unique identification numbers or barcodes to individual items (such as a strip of tablets or a bottle of medicine) for computerized serialization and tracking is becoming among the best ways to maintain product integrity.

Among newer innovations and latest trends in serialization in the pharmaceutical supply chain.

Data Encryption and Data Security

The ultimate aim of pharmaceutical supply chain serialization is to ensure consumers get the right drugs at the right price and quality. At the same time, companies that trace and track their products end up knowing where each shipment is at any given moment.

Verification for this requires very strict data management and security. One way to get it done is through computerized encryption that lets only designated people read the data.

The pharmaceutical industry loses on average 4.5% of its potential revenue because of supply chain inefficiencies.

Recalling Individual Products

The pharmaceutical industry is highly susceptible to recalls caused by poor packaging, leading to contaminated products that could harm patients.

Previously, these recalls were made at batch-levels, causing massive revenue loss as well as disrupting the supply chain. Narrowing defective medicines to individual units makes it possible for companies to limit recalls to specific products. The same serialization can then be used to determine when and where the product was altered or contaminated.

Figure: 2 Serialization to Improve Track and Trace

Use of Advanced Analytics

By studying buying trends, life sciences organizations and their research groups constantly work to understand what consumers need and want. Using advanced analytics applications like Microsoft Power BI to create in-depth business intelligence reports is becoming the best way to help realize and act on these patterns. Power BI’s dashboards take advantage of interactive visualizations to help users make informed decisions about if and when they need to alter their production schedules to keep up with market demand.

Enhanced Visibility at Every Level of Supply Chain

Serialization is a good way for companies to provide accountability regarding compliance with government regulations. It’s also an excellent way to enhance visibility and improve monitoring at every level of the pharmaceutical supply chain. Knowing how much you have and where to reduce stock-outs improves the overall distribution and ensures your products are available when and where the consumers want them.

Barcoding and Labeling

Barcodes can provide a lot more information than just a serial number alone. You can include electronic links to product information sheets, safety data sheets, ingredients, storage requirements, shipping requirements, dosage levels, and other information. All a worker needs to scan a code made with advanced label-making capabilities using a barcode reader or cellphone to access this data on the spot.

$200 billion (10%): that is the global monetary cost of counterfeit drugs according to the World Health Organization.

One million: That is the annual cost in human lives each year from fake and altered medicines according to Interpol.

Serialization’s Impact on Companies

In the United States, the serialization of all drugs at the sealable unit and case level became a requirement with the passage of the Drug Supply Chain Security Act (DSCSA) in November, 2017. This requirement had an impact on pharmaceutical companies and their supply chain vendors that had to ensure serialization of all drugs at an individual container or dose level with barcodes for better tracking and tracing.

Ultimately however, this has led to a number of benefits including:

- Better market visibility down to individual drug demand. This helps by allowing for more efficient drug distribution.

- Warehouses and inventories need to be equipped with a fortified drug distribution plan.

- Better understanding and communication among cross-functional teams. Since serialization provides an inflow and outflow of different information, life sciences researchers, packaging personnel, IT experts, and distributors alike can share any data available for a particular drug.

Challenges in Serialization

Like any other change across the supply chain, serialization has its own set of challenges, including:

- Hardware Setup and Updates

Companies need to ensure they have the right equipment and supplies on hand at all times to print the labels, barcodes and seals required for serialization. - Steady Flow of the Production Line

Introducing serialization and the training required to understand the process might have an impact on the production line early on as labeling each and every product may initially slow down the process. - Higher Costs

Adding serialization to an existing process often means adding costs in terms of hardware, software, and people. These costs can be reduced by using pooled investments and sustainable hardware and software applications. - Skilled Personnel Shortage

Newer, digital methods of serialization require a workforce that understands what needs to be done. Companies are facing a lack of a skilled, technically sound employee base to implement their serialization strategies. - Technical Glitches

Serialization should ultimately require minimal human intervention, aiming to significantly reduce manual errors. With anything else so integrated, you will need to make sure any technical issues can be identified and addressed in a timely manner to avoid any major disruptions to production.

XcelPros’ Microsoft Dynamics 365 solutions enable pharmaceutical companies to seamlessly implement serialization for better compliance and enhanced track and trace.

Key Benefits of Serialization in Operations

Pharmaceutical companies able to take advantage of advanced digital serialization processes for their supply chain operations often realize a number of benefits, including

- Easy end-to-end implementation across the supply chain

- Efficient sealing of supply chain loopholes to combat drug counterfeiting and packaging mistakes

- Minimal human intervention required, making serialization a fool-proof, effective way to ensure brand authenticity and reduce batch recalls

- Full compliance with government traceability regulations

- Reduction of counterfeit drugs and compromised quality.

Final Thoughts

Overall, serialization in the pharmaceutical supply chain plays a significant role in avoiding drug theft, counterfeiting, batch recalls, and other potential hazards. Every pharmaceutical company needs to have a unique serialization process to meet its requirements. Newer serialization software uses advanced analytics for better drug distribution and fewer stock-outs.

With government mandates requiring pharmaceutical companies and their supply chain vendors to understand and master the technical details of implementing serialization at batch and case levels in an effort to fortify their supply chain and enhance visibility, these companies need to be prepared to overcome any challenges that arise. Is your track and trace solution ready?