At a Glance

- The Covid-19 pandemic not only came as a health threat, but it also disrupted the world’s socio-economic thread. Industries like pharmaceutical and biotechnology were at the forefront attempting to find solutions.

- Pharmaceutical industry supply chain challenges that concerned top executives include shortage of raw materials, unprecedented changes in demand pattern, inability to plan lead-times and shortage of labor.

- The pharmaceutical industry’s supply chain efficiency still has room for improvement and may need some transformative changes to thrive in the new normal.

Pharmaceutical supply chain challenges have been a major cause of concern for the industry throughout 2020. The challenges are still very much prevalent, even as the world moves ahead in the era of the new normal. This pandemic caused a major global socio-economic impact and led to disruption in almost all facets of the industry. Modern companies equipped with the right tools and technologies have been quick to adjust to the changes. Organizations that still functioned on archaic systems were struggling to adapt to the business processes changes brought about by the pandemic. Slow to adapt companies had to put in more effort to understand the needed changes and adapting to the changes without the right technologies in place was daunting.

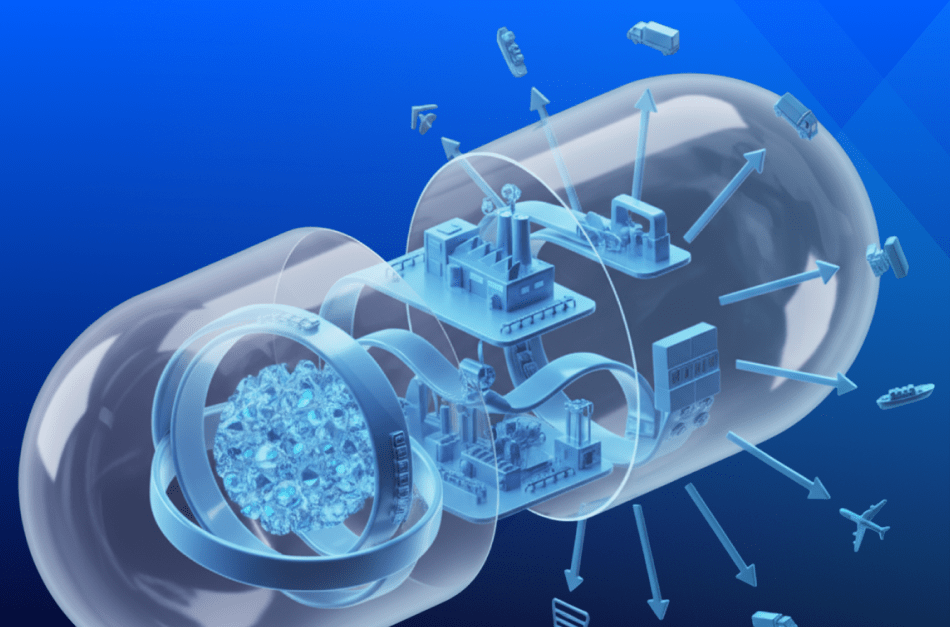

Figure: 1Major Pharmaceutical Supply Chain Disruptors

Added to that was the inability of companies to quickly onboard onto newer applications and get into the rhythm of modern cloud-based solutions. Some of the major issues that surfaced during the pandemic are:

- a.The demand for therapeutics and/ or vaccines led to an overdrive of pressure on the industry.

- b.The lack of resources and slow global travel have increased pharmaceutical supply chain disruptions.

- c.Changes in quality standards have added new tasks to the workforce that were not part of their day-in-the-life and had to adapt to rapidly.

- d.Changes in quality testing created adjustments in the test specification and additional steps in testing.

- e.Disintegrated systems made it harder for the workforce to stay agile and adjust to the changes that came their way.

- f.Inability to manage supply-demand cycles.

70%

of the leaders said that the pharmaceutical supply chain was vulnerable to ongoing problems caused by the continuation of the pandemic and that on-time, in-full delivery of medicines had deteriorated by almost 50 percent within the first few months of the pandemic.

Source: IDC Whitepaper Report

While modern manufacturing companies did rise to the challenges and leveraged solutions such as cloud applications, automation, Artificial Intelligence (AI), Machine Learning, and Big Data to their advantages, many risk-averse pharmaceutical companies are still prone to supply chain challenges due to the lack of right tools in place to make them nimble. Let us look at the top 8 concerns of the pharmaceutical industry supply chain that still are pressing concerns:

1.Unprepared for further disruptions: Different countries worldwide are struggling with second or third waves of the pandemic (and many have reported new mutant strains of the virus). These continuous disruptions have led to major disturbance in the pharmaceutical distribution system.

2.Technological bottlenecks are prevalent: The pharmaceutical industry has been highly apprehensive and traditional in adopting newer technologies. While the last decade has seen major leaps, there are still many bottlenecks in leveraging technologies to their full potential.

3.Shortage of raw material: The inability to plan effectively during the pandemic can cause many hurdles if procuring raw materials. Knowing lead times and accurate inventory quantities without a planning tool can slow you down significantly as you try to extrapolate data and understand your supply schedule.

4.Standard operating procedures and processes: As workforce within the pharmaceutical industry needs to be onsite, proper SOPs need to be set. This would add new processes that warehouse personnel need to be trained on. A lack of the right kind of training tools can add to the burden.

5.Managing cold storage facilities is resource-intensive: Some of the products have to be stored at very low temperatures to ensure that the potency and formulation remain intact. This would need pharmaceutical supply chains equipped with refillable dry ice containers or specialized freezers, both of which are not budget-friendly options.

6.Pharmaceutical safety guidelines and regulations differ across Borders: The pharmaceutical industry has to be very tenacious and alert when adhering to the safety guidelines and regulations. However, pharmaceutical supply chain challenges get magnified as the raw materials and drugs cross borders and these regulations keep on changing.

7.Rapid drug delivery: The historical task of bringing medicines to market is a race against time. Pharmaceutical operations and supply chain management handling need to be as efficient as they come to ensure lesser bottlenecks and plausible errors in these testing times.

8.Lack of integration across processes: When your inventory, manufacturing, labeling operations don’t talk to each other and are manually managed, the error rate will go up and business productivity will go down.

The year 2021 will probably push the pharmaceutical supply chain to its maximum limit yet. However, with the right strategy, technologies, and solutions, the pharmaceutical sector can rise up in these challenging times.

Key Takeaways

- Pharmaceutical manufacturing and distribution companies are facing a once-in-a-lifetime level of challenge and they need to streamline their operations to ensure the efficiency of supply chains.

- The pharmaceutical supply chain challenges have been a part of this sector for a long time and companies that are not properly equipped will tend to struggle more than others. This is the right time to transform to be equipped with the right technologies for a better tomorrow.

Take a assessment to get recommendations in transforming your pharmaceutical supply chain.