Ensuring your customers receive their orders punctually is an essential part of any successful enterprise – especially true when it comes to manufacturing. Many organizations use scheduling and capacity planning systems to guarantee their services and products reach their destination without delay. Microsoft Dynamics 365 offers optimal job scheduling and capacity planning solutions that can give you a competitive edge and satisfy your customers. Through this post, we’ll be looking at how Dynamics 365 can facilitate efficient job scheduling and capacity planning to guarantee timely deliveries.

The importance of on-time delivery

Delivering products on time is essential for businesses that want to maintain a successful reputation. Customers expect their orders to arrive when promised, and any delays in the supply chain can lead to lost sales and damaged relationships. On-time delivery is even more crucial in the current competitive landscape, where customers have an abundance of options to choose from.

Having a reliable system in place to ensure that orders are delivered on time is critical for any business. Job scheduling and capacity planning are key tools designed to help companies achieve this goal.

- Job scheduling involves creating plans for how to use resources, including people and machines, to complete tasks.

- Capacity planning focuses on understanding the maximum capacity of resources so that orders can be completed efficiently.

To streamline job scheduling and capacity planning, more companies are utilizing cloud-based Supply Chain Management systems like Microsoft Dynamics 365. With its easy-to-use graphical user interface (GUI), users can quickly create job schedules without writing complicated code or manually entering data. It also provides insights into capacities and resources used so that users can make better decisions on resource allocation.

This helps organizations optimize their operations while meeting customer expectations of timely delivery. Additionally, the cloud-based solution allows businesses to access data across multiple sites or departments, giving them visibility into what needs to be done.

How job scheduling and capacity planning can help

As described above, job scheduling and capacity planning have become essential tools for businesses that want to ensure on-time delivery. Carefully planned and executed job scheduling and capacity planning can help improve efficiency, reduce costs, and prevent bottlenecks from forming.

With efficient job scheduling and capacity planning, businesses can reduce lead times, increase on–time delivery, and improve customer satisfaction. These are all things that can increase a business’s revenue. Job scheduling and capacity planning can help businesses plan for potential problems and take preventive measures to avoid delays or other issues to save time, money, and effort.

What to consider when implementing job scheduling and capacity planning

Job scheduling and capacity planning can be implemented for any business that needs to ensure their orders are delivered on time. However, this process can become complex when managing multiple customer orders. To ensure successful and timely order fulfilment, several factors must be considered when implementing job scheduling and capacity planning in your supply chain.

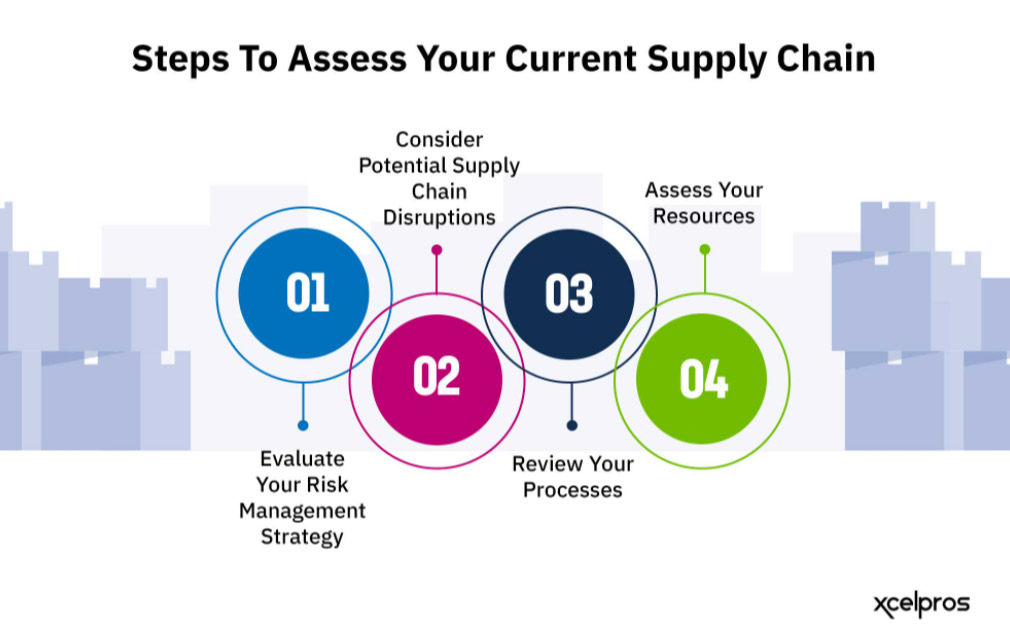

Figure 1:Considerations While Implementing Job Scheduling and Capacity Planning

One of the first things businesses can do is review the demand for each product or service. This helps determine the resources needed to complete orders within a desired period. It would help if you also considered any external factors that may impact the capacity of your resources, such as changing customer demand, unexpected delays, or seasonal fluctuations.

It’s also important to consider the availability of your resources. Ensure you understand your employees’ current workload, their skills, and any additional tasks they may need to complete to finish the job. This will help you effectively manage staffing and allocate resources to fulfil orders on time.

Finally, don’t forget to look at the tools you use for job scheduling and capacity planning. It is important to have a system that allows for easy visibility and management of jobs, resources, and customer data. This way, you can ensure that every aspect of the job scheduling and capacity planning process runs smoothly and efficiently.

This is a perfect case for solutions like Microsoft Dynamics 365, which offers an intuitive job scheduling and capacity planning solution that makes it easier to manage these processes. With Microsoft Dynamics, businesses can easily track customer orders, view available resources, and manage workloads—all while providing greater transparency into the entire process. As a result, businesses can deliver on-time orders with confidence.

How Microsoft Dynamics can help

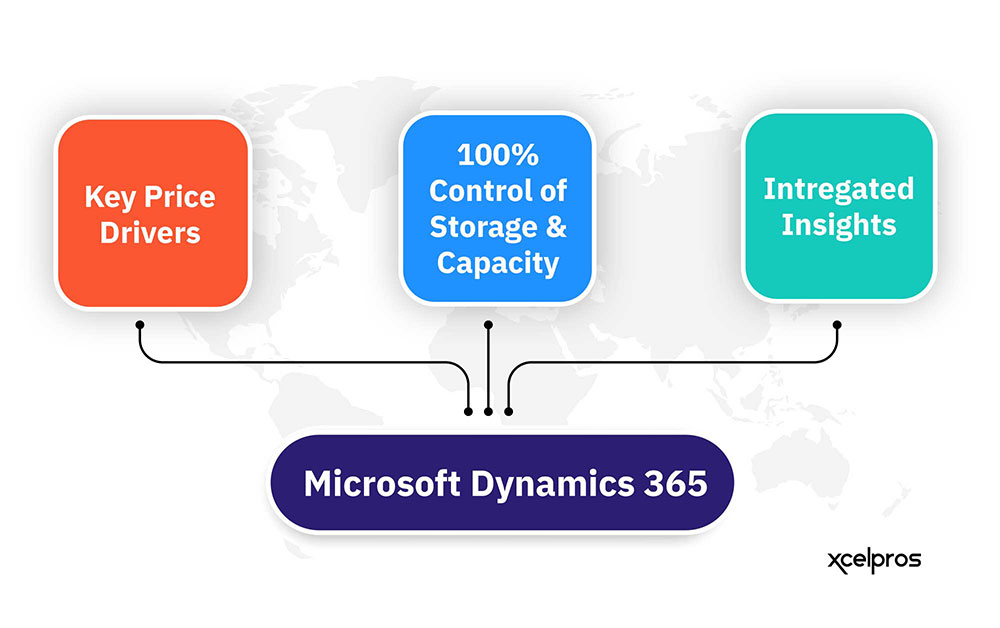

Microsoft Dynamics 365 (D365) is a well-known cloud-based enterprise resource planning (ERP) system that enables businesses to efficiently manage their entire supply chain, including resources and processes. D365 provides users with comprehensive tools to manage job scheduling and capacity planning, including features such as project-level resource scheduling, job costing, inventory control, job tracking, and demand forecasting.

Things like job scheduling and capacity planning can be difficult to implement independently, which is why many businesses turn to Microsoft Dynamics for help. Microsoft’s D365 provides powerful job scheduling and capacity planning tools, allowing businesses to manage resources and meet customer expectations easily.

With D365, businesses can;

- create optimized production plans,

- set production goals, and

- monitor progress to ensure timely delivery.

The software also includes dashboards and performance analytics, making it easy to view overall performance quickly and easily. Additionally, D365 allows users to track inventory levels and determine when additional materials must be ordered to meet deadlines. This helps ensure all necessary materials are available and orders are processed as quickly as possible. Moreover, it also helps reduce costs associated with excess inventory.

Using D365 to automate processes like job scheduling and capacity planning helps businesses save time and money by reducing manual labour costs. This leads to improved efficiency, reduced expenses, and better customer satisfaction.

D365’s job scheduling helps businesses optimize their operations by allocating the right resources at the right time. Users can easily identify potential delays and adjust in real time by assigning jobs to the most qualified team members and grouping them into batches. This helps businesses plan and execute their operations on time.

D365’s capacity planning makes it easier for businesses to plan for future needs and better manage their resources. The system offers various reporting options that allow users to track their current and projected capacities, identify any gaps in resources, and plan accordingly. With this information, businesses can optimize their resources, adjust their work schedules to meet customer demands, and improve on-time delivery rates.

Microsoft Dynamics 365 provides users with a comprehensive suite of tools to manage job scheduling and capacity planning effectively. By leveraging the features offered by D365, businesses can optimize their supply chain operations, reduce delays, and improve their overall on-time delivery rates.

Schedule a call today for more information and to find out how we can help streamline your delivery.